Production method for composite anisotropic rare earth permanent magnetic material with good temperature characteristics

An anisotropic, rare earth permanent magnet technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of complex protection mixing process, high cost, and easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Manufacturing of samples

[0037] a. R 1 Manufacture of FeBM anisotropic coarse powder

[0038] As one of the magnetic powders used in the present invention, R 1 FeBM is obtained by HDDR process. The specific manufacturing method is to make the atomic ratio into Nd 12.5 Fe bal B 6.0 Ga 0.3 Nb 0.3 The alloy raw materials are loaded into the vacuum induction furnace, and the vacuum is lowered to less than 1×10 -2 Pa, melting and casting under the protection of argon, and homogenizing the alloy at 1403-1423K for 35 hours under the protection of argon. The homogenized alloy is crushed to particles smaller than 10mm, and put into the HDDR furnace for treatment. The treatment process is: hydrogen charging at room temperature 0.1MPa, heating to 673K, reducing hydrogen partial pressure to 0.03-0.06MPa, and increasing the temperature under this pressure to 810°C and keep it for 2 hours, then remove the hydrogen until the vacuum in the furnace reaches 1×10 -2 Pa, th...

Embodiment 2

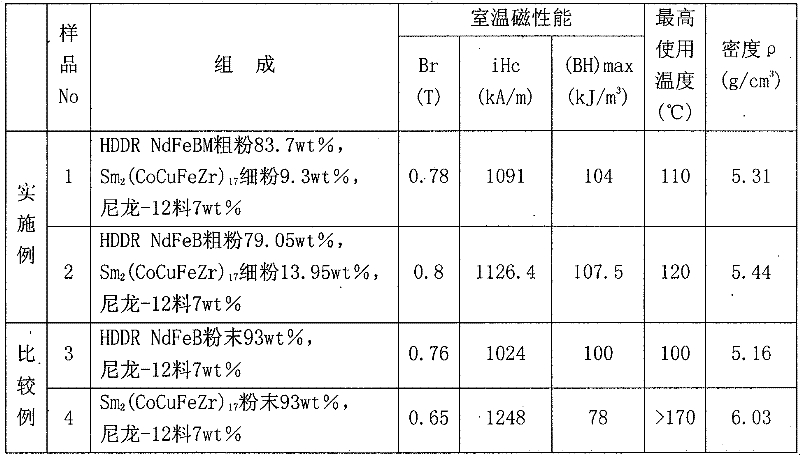

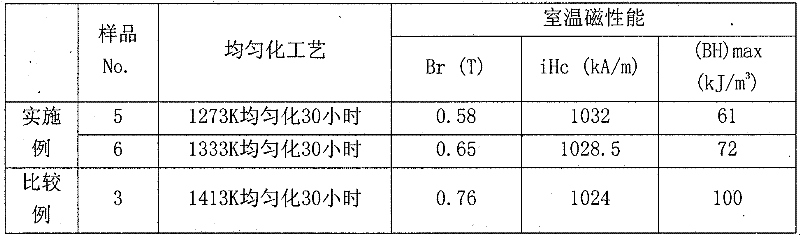

[0053] According to the manufacturing method of Example 1, only the temperature for homogenizing the steel ingot was changed, and the results obtained are shown in Table 2.

[0054] Table 2. The effect of different homogenization treatment systems of single NdFeB material on the magnetic properties of injection magnets

[0055] (Nylon-12 content 7wt%)

[0056]

[0057] From the data of Br in Table 2, it can be seen that the choice of homogenization treatment temperature is very important. Samples No.5 and No.6 show only weak anisotropy characteristics, and the lower the temperature, the weaker the anisotropy.

Embodiment 3

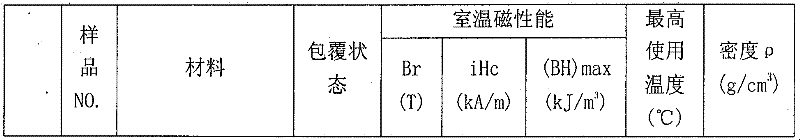

[0059] According to the manufacturing method of embodiment 1, only different coating states are selected, the results are shown in Table 3,

[0060] Table 3. 79.05 wt% HDDR NdFeB coarse powder and 13.95 wt% Sm 2 (CoCuFeZr) 17 Effect of Different Coating States of Fine Powder on Magnetic Properties of Injected Magnets (7wt% Nylon-12)

[0061]

[0062]

[0063] It can be seen from Table 3 that no matter whether the two magnetic powders are coated or only the fine powder is coated, the magnetic properties of the magnets made are better than those made from the magnetic powders that are not coated. This is mainly due to the density Due to the contribution of the magnetic powder, the coating treatment of the magnetic powder also has some improvement effects on the material iHc and the maximum service temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com