Biological leaching-solvent extraction-electrodeposition recovering method for heavy metal copper in sludge

A technology of biological leaching and recovery method, applied in the field of environmental engineering, can solve problems such as no reports, and achieve the effects of simple equipment, easy operation and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 reclaims copper in the municipal sludge 1 of an industrial park in Suzhou

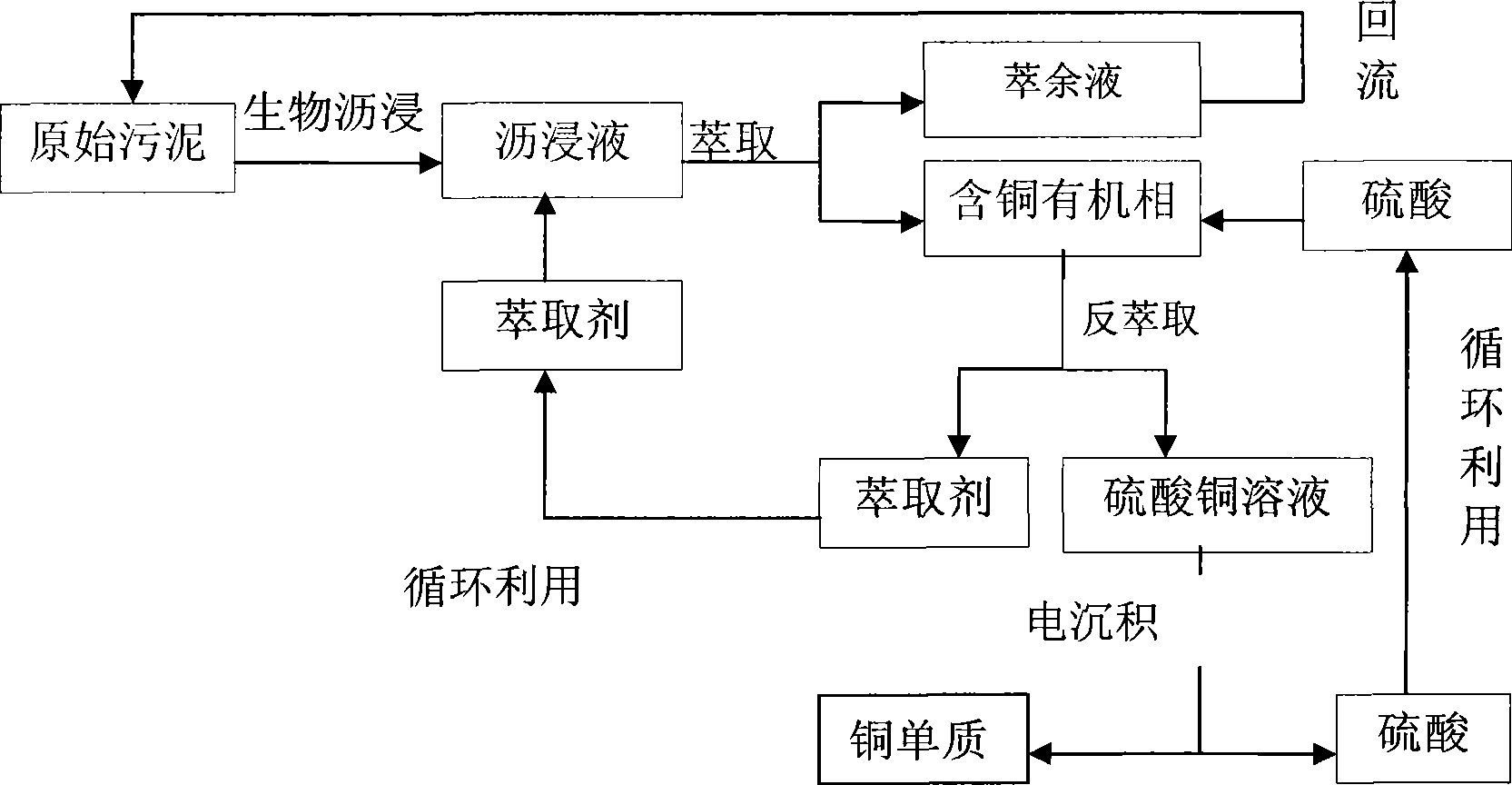

[0046] According to the technique mentioned in the present invention, according to flow process (see attached figure 1 ) to treat the urban sludge of an industrial park in Suzhou and recover the copper in it.

[0047] Copper dissolution stage by bioleaching: the microorganisms used in bioleaching are compound acidophilic thiobacteria (Acidithiobacillus thiooxidans TS6 and Acidithiobacillus ferrooxidans LX5); the solid content of the test sludge is 2.87%, the pH is 6.59, and the organic matter is 46%. Total copper 7432mg / kg (calculated as dry matter).

[0048] Add the compound acidophilic thiobacillus inoculum (the density of thiobacillus is about 108 CFU / mL) and the original sludge after domestication and enrichment culture into a 10L reactor at a volume ratio of 1:, and add sulfur powder, Ferrous iron is used as an energy source (the addition amount is 2.0g / L). Under the conditio...

Embodiment 2

[0051] Embodiment 2 reclaims the copper in the municipal sludge of an industrial park in Wuxi

[0052] According to the technique mentioned in the present invention, according to flow process (see attached figure 1 ) to treat the municipal sludge in an industrial park in Wuxi and recover the copper in it.

[0053] Copper dissolution stage by bioleaching: the microorganisms used in bioleaching are Acidithiobacillus thiooxidans TS6 and Acidithiobacillus ferrooxidans LX5; the solid content of the test sludge is 2.93%, pH6.56, organic matter 43%, total Copper 12750mg / kg (calculated as dry matter).

[0054] The compound acidophilic Thiobacillus inoculum (the density of Thiobacillus is about 10 8 CFU / mL) and the original sludge in a volume ratio of 1: add them to a 100L reactor, and add sulfur powder and ferrous iron as energy materials (the addition amount is 2.0g / L), under the condition of ventilation and aeration , stirring and mixing, so that the microorganisms can better act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com