Conductive composite material, preparation and use thereof

A technology of conductive composite materials and conductive fillers, which is applied to conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of reducing the mechanical properties of materials, disorder, and adverse effects on the mechanical properties of conductive polymer materials, so as to eliminate the difficulty of recycling. , the effect of easy recovery and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

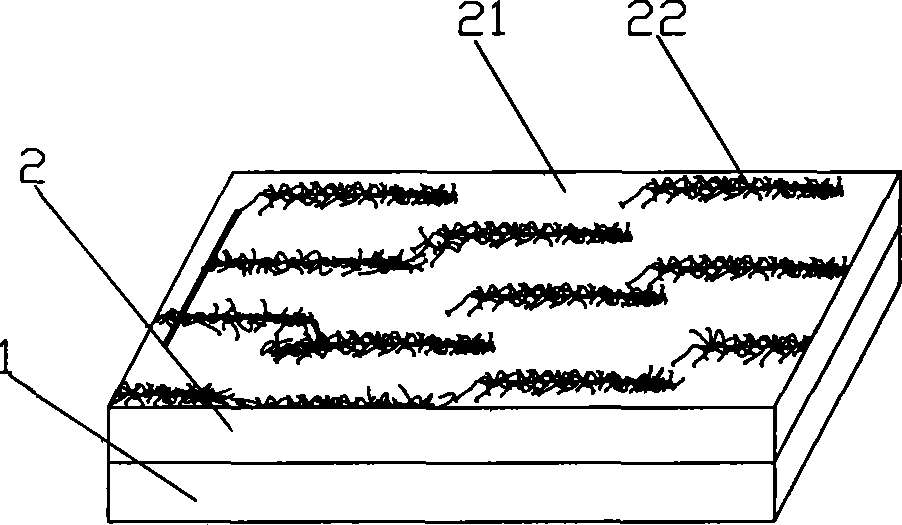

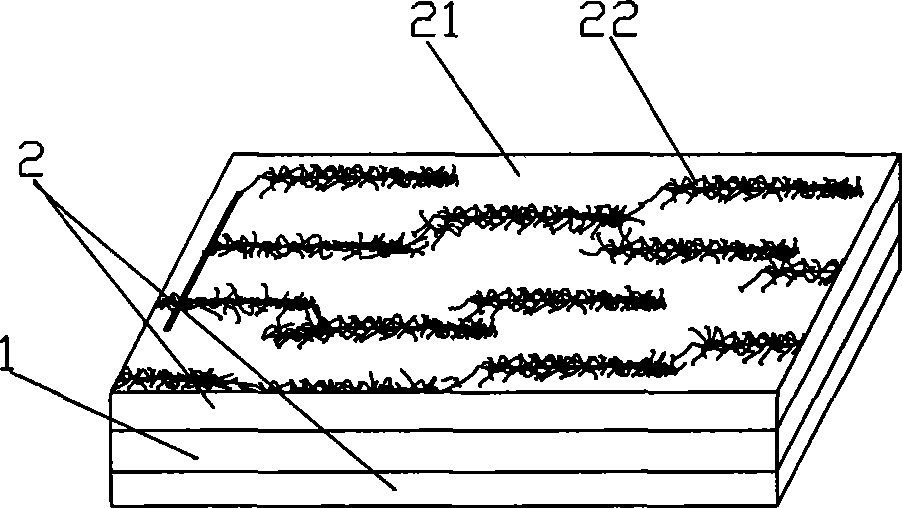

[0040] figure 1 It is a schematic diagram of the first embodiment of the flat layer structure of the present invention, as shown in the figure: the conductive composite material of this embodiment includes a second polymer 1 and a conductive composition 2 combined with the second polymer 1 and having a continuous phase , in this embodiment, the second polymer 1 is polypropylene; the conductive composition 2 is composed of a first polymer 21 and a conductive filler 22 contained in the first polymer 21 and forming a conductive network, in this embodiment The first polymer 21 is a polypropylene heteromolecular polymer, which meets the requirement that the melting temperature of the second polymer 1 is higher than the melting temperature of the first polymer 21;

[0041]In this embodiment, the conductive composite material is a belt-shaped layered structure formed of a layer of conductive composition 2 and a layer of second polymer through hot pressing to form a flat layer structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com