Method for modulating zinc-nickel alloy and nickel combined multi-layer membranous by electrochemical deposition component

A component modulation, zinc-nickel alloy technology, applied in the field of electrochemical deposition component modulation Zn-Ni/Ni or Ni/Zn-Ni multilayer film, can solve the problems of high cost, long preparation time, high equipment requirements, etc. Achieve smooth and bright coating, high current efficiency, and solve the effect of poor bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

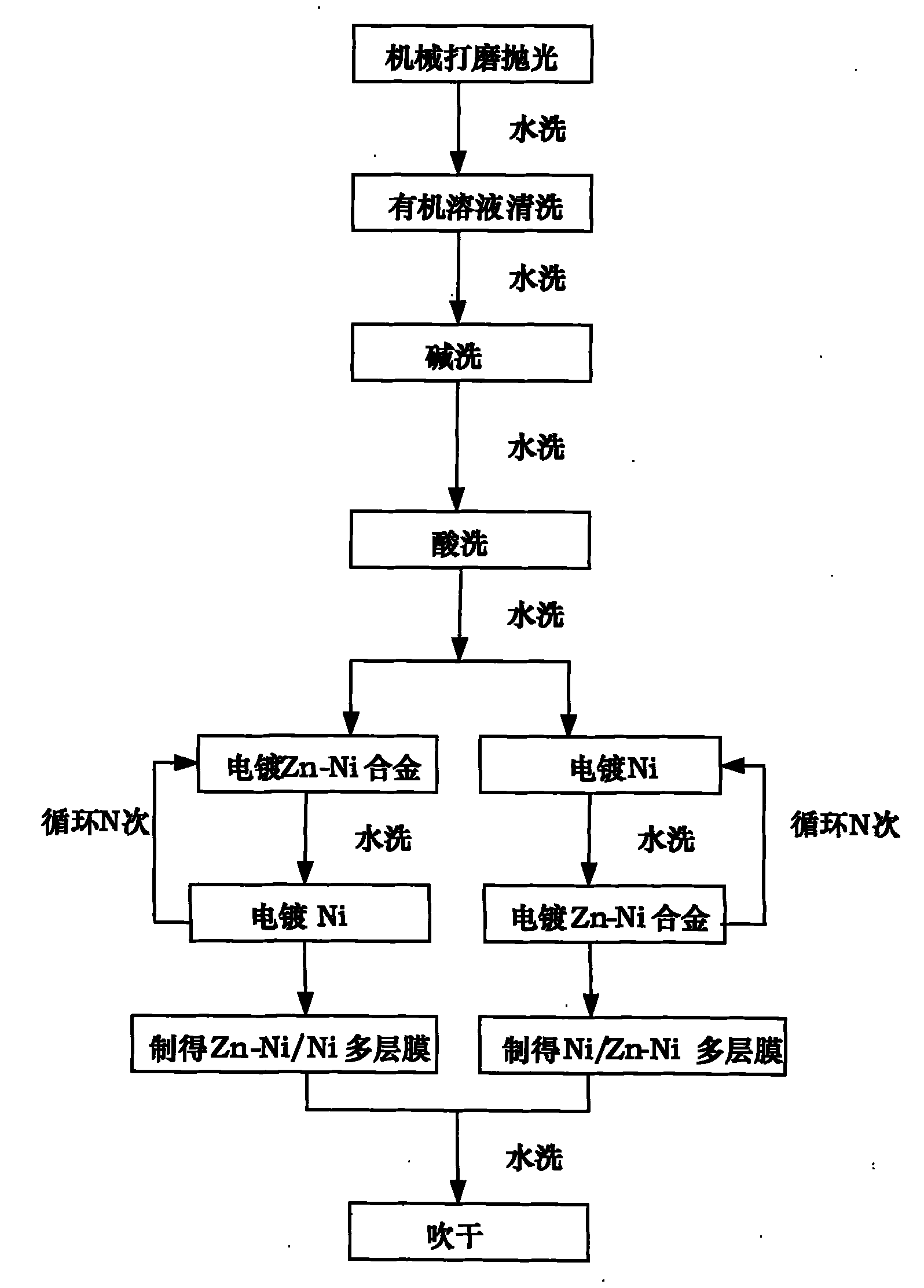

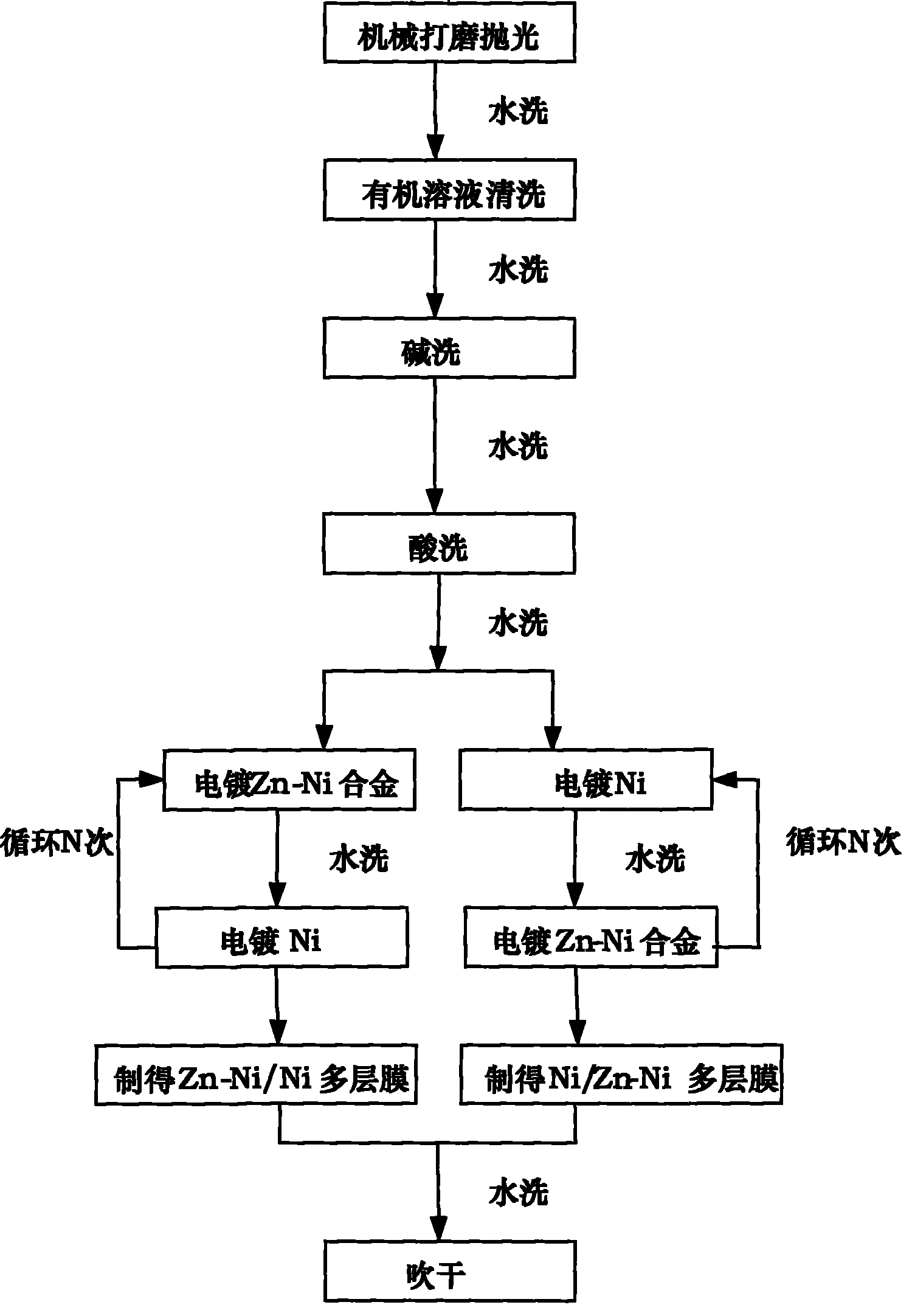

[0031] The multi-layer film preparation method of zinc-nickel alloy and nickel combination provided by the invention, the preparation process is as follows figure 1 As shown, the specific implementation steps are as follows:

[0032] The first step is to prepare alkaline cleaning solution, pickling solution and electroplating solution.

[0033] Alkaline lotion contains NaOH, Na 3 PO 4 12H 2 O, Na 2 CO 3 10H 2 O, Na 2 SiO 3 ·nH 2 Aqueous solution of O, which contains 60-80g of NaOH per liter of alkaline washing solution, NaOH 3 PO 4 12H 2 O 20~40g, Na 2 CO 3 10H 2 O20~40g, Na 2 SiO 3 ·nH2 O 20 ~ 40g, the rest is water.

[0034] The pickling solution uses HCl solution, and each liter of pickling solution contains 4-8 mL of HCl.

[0035] Alkaline Zn-Ni alloy electroplating solution contains ZnO, NiSO 4 , NaOH, complexing agent, additives and brightener aqueous solution, containing ZnO 10~30g per liter of plating solution, NiSO 4 5-13g, NaOH 100-140g, in addit...

Embodiment 1

[0061] Embodiment one: Electroplating Zn-Ni / Ni and Ni / Zn-Ni multilayer films on 30CrMnSiA steel substrate.

[0062] The first step is to prepare alkaline cleaning solution, pickling solution and electroplating solution.

[0063] Each liter of alkaline washing solution contains: NaOH 70g, NaOH 3 PO 4 12H 2 O 30g, Na 2 CO 3 10H 2 O 30g, Na 2 SiO 3 ·nH 2 O 30g. The rest is water.

[0064] Each liter of pickling solution contains 6mL of HCl.

[0065] Each liter of alkaline zinc-nickel alloy electroplating solution contains: ZnO 10g, NiSO 4 5g, NaOH 120g, complexing agent tetraethylenepentamine 3mL, triethanolamine 38mL, ammonia water 10mL, additive DE 1.5mL, CTAB 2g, brightener ZB 3mL, vanillin 0.2g, and the rest is water.

[0066] The plating solution for electroplating nickel contains per liter: 150g of nickel sulfate, 200g of sodium citrate, 10g of nickel chloride, 20ml of triethanolamine, 40g of magnesium sulfate, and the rest is water.

[0067] The second step...

Embodiment 2

[0087] Embodiment two: Electroplating Ni / Zn-Ni multilayer film on stainless steel substrate.

[0088] The first step is to prepare alkaline cleaning solution, pickling solution and electroplating solution.

[0089] The preparation of alkaline washing solution and pickling solution is the same as in Example 1.

[0090] Electroplating zinc-nickel alloy plating solution is ZnO, NiSO 4 , NaOH, ammonium citrate, tetraethylenepentamine, triethanolamine, EDTA, phytic acid, DE, thiourea, and each liter of alkaline zinc-nickel alloy plating solution contains: ZnO 20g, NiSO 4 10g, NaOH 100g, complexing agent ammonium citrate 15g, tetraethylenepentamine 20mL, triethanolamine 40mL, EDTA 15g, additive phytic acid 0.15mL, DE 9mL, brightener thiourea 1g, the rest is water.

[0091] Each liter of electroplating nickel plating solution contains: 100g of nickel sulfate, 75g of potassium pyrophosphate, 15g of citric acid, 50mL of ammonia water, and the rest is water.

[0092] The second st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com