Method and device for producing n-butyric acid by microbial catalysis

A technology of n-butyric acid and microorganisms, which is applied in the field of microbial catalytic production of n-butyric acid, can solve the problems of microbial toxicity and low extraction efficiency of extractants, and achieve the effects of reducing toxicity, prolonging effective running time, and avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 The device for the production of n-butyric acid by microbial catalysis of the present invention

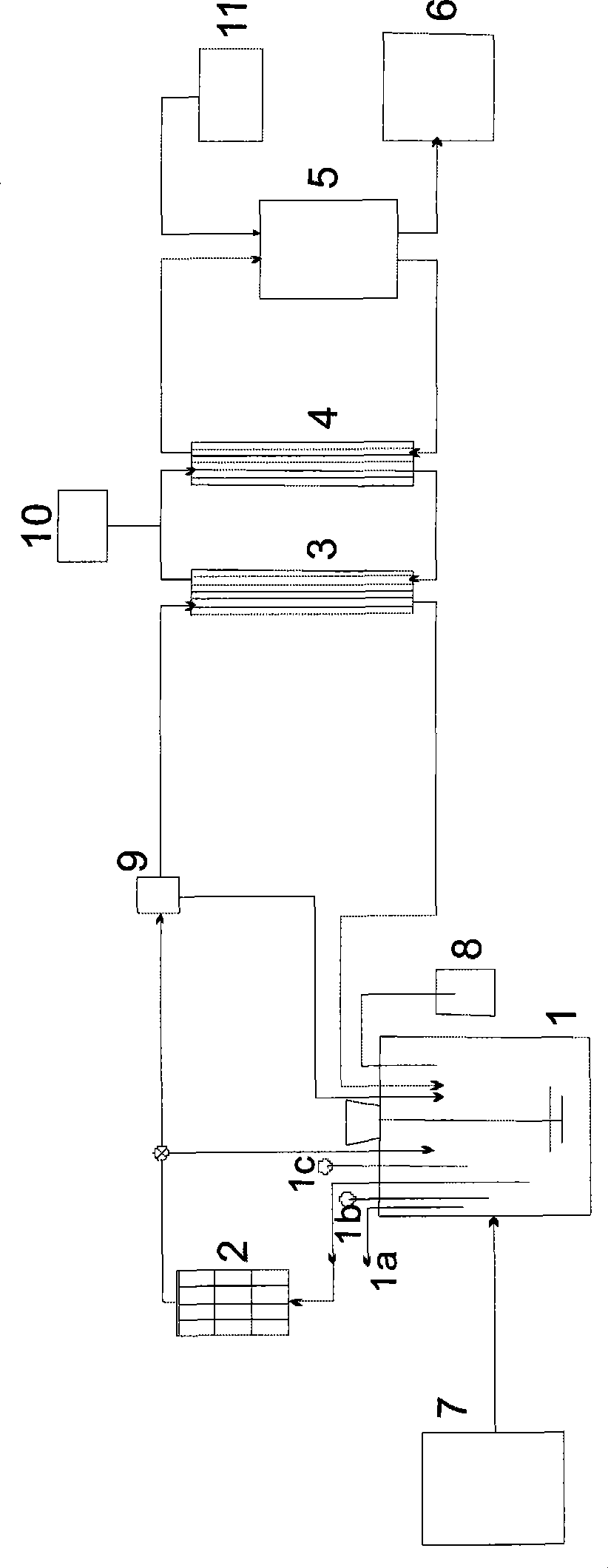

[0034] See attached figure 1 , the device for fermenting and producing n-butyric acid of the present invention comprises: fermenter 1, immobilization reactor 2, extracting device 3, stripping device 4, stripping agent receiving tank 5, salting-out tank 6, and storage tank 7, acid Alkali bottle 8, bacterial liquid separation device 9, extractant storage tank 10, stripping agent storage tank 11 and the pipelines, pump valves, etc. connecting them.

[0035] The immobilization reactor is a closed container filled with an immobilization carrier in a folded manner, and the immobilization carrier is composed of an immobilization carrier material wound on a support. The support can be sheet or mesh stainless steel or glass; the immobilized carrier material can be fibers such as cotton cloth, etc., or synthetic high molecular polymers such as polyvinyl alcohol, etc.

...

Embodiment 2

[0037] Embodiment 2 The method for the production of n-butyric acid catalyzed by microorganisms of the present invention

[0038] Proceed as follows:

[0039] (1) Preparation of seed solution

[0040] After the seed medium is bottled, cover it with a layer of liquid paraffin about 5-10 mm thick, sterilize it under high pressure at 121°C for 20 minutes, inoculate Clostridium tyrobutyricum, and culture it statically at 35-37°C for 48 hours to obtain the seed liquid for later use .

[0041] The formula of the seed medium is as follows: glucose 10g / L, peptone 5g / L, yeast extract 5g / L, beef extract 5g / L, ammonium nitrate 1g / L, ferrous sulfate 0.03g / L, sodium acetate 3g / L, chloride Sodium chloride 5g / L, soluble starch 1g / L, cysteine 0.5g / L, pH7.0.

[0042] (2) Preparation of microbial suspension

[0043] Put the Clostridium culture medium into the fermenter, and sterilize it under high pressure at 121°C for 25 minutes. After cooling, nitrogen gas is introduced to reduce the ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com