Grinding wheel and use thereof for grinding hard-face roller

A grinding wheel and grinding technology, applied in the field of grinding wheels, can solve the problems of easy to produce wear marks on the surface of the roll, poor roll shape accuracy, small thickness of wear debris, etc., and achieve the effects of improving the environment, reducing the amount of sand and mud, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

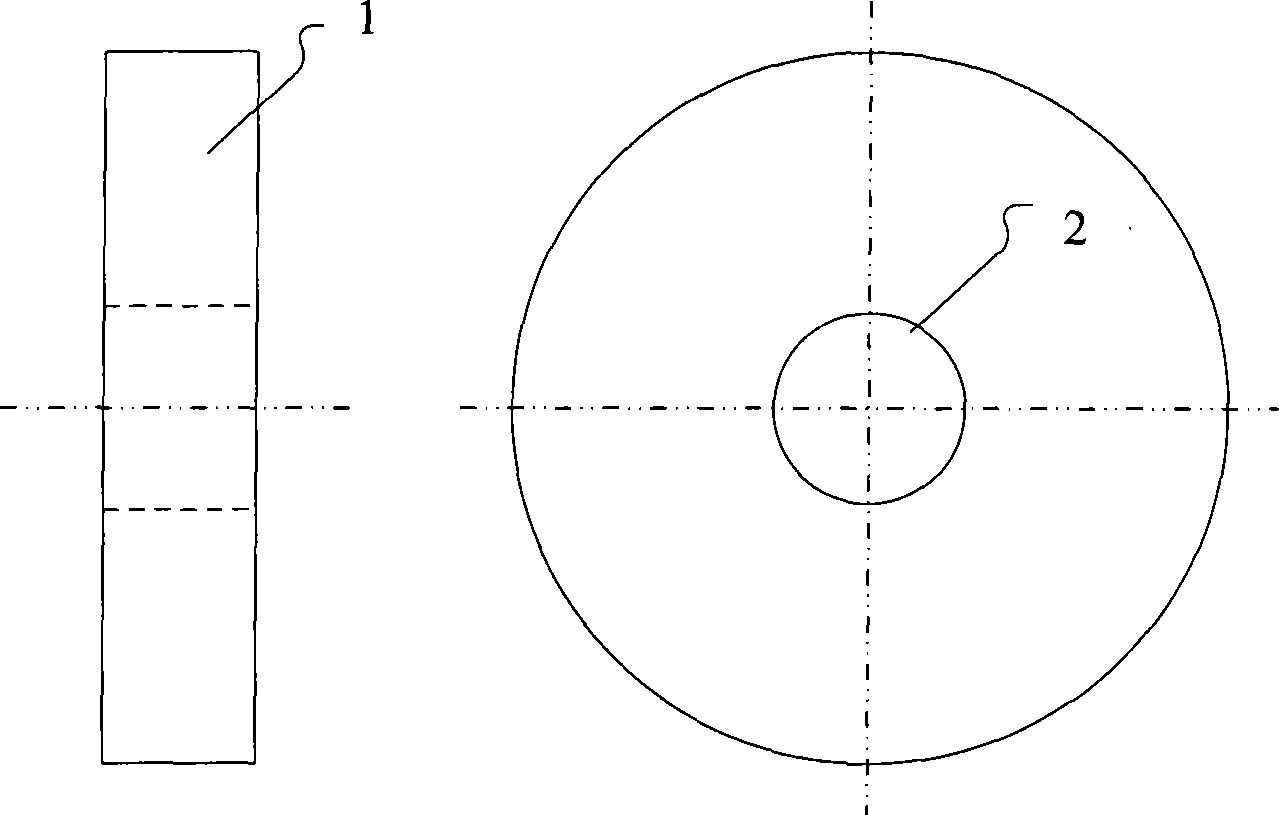

[0076] 1. Production of grinding wheel:

[0077] ●Composition of grinding wheel: 30% aluminum oxide, 30% single crystal corundum, 40% silicon carbide.

[0078] ●The process of making grinding wheel:

[0079] Raw material preparation: select and weigh materials according to the weight ratio of alumina, single crystal corundum and silicon carbide. The hardness of all abrasives is neutral hardness, the particle size is 36 grains / hour, and the diameter is 550 microns. (See grinding wheel standard, ANSI (American National Standards Institute) B7.1)

[0080] Grinding wheel forming: After the three kinds of abrasives are added to the resin bond and fully stirred and mixed, they are pressed into shape by a press, and then the grinding wheel is cured after drying.

[0081] Machining: After the grinding wheel blank is ground, the geometric dimensions are processed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com