Silicon dioxide surface treating method by precipitation method and use thereof

A technology of silica and surface treatment, applied in the direction of dyeing organosilicon compound treatment, fibrous filler, etc., can solve the problems of increased viscosity, unfavorable flow of liquid silicone rubber, and inconsistency, and achieve good fluidity, simple use, and easy industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Surface treatment method of precipitated silica

[0023] Add 100 parts of 350cp methylpolysiloxane and 8 parts of hexamethyldisilazane to the stirring tank under nitrogen atmosphere, divide 100 parts of precipitated silica into 6 times and decrease the amount each time The method is to add methyl polysiloxane, and the stirring time is controlled to be 30 minutes each time, and the reaction is carried out at a temperature below 130°C for 10 hours, and then vacuumed at 140°C for 12 hours to remove small molecules, and finally add 100 parts of 50000cp hydroxyl silicone oil, After mixing evenly, it is ground by a three-roll mill to obtain a suspension of silicon dioxide and polysiloxane.

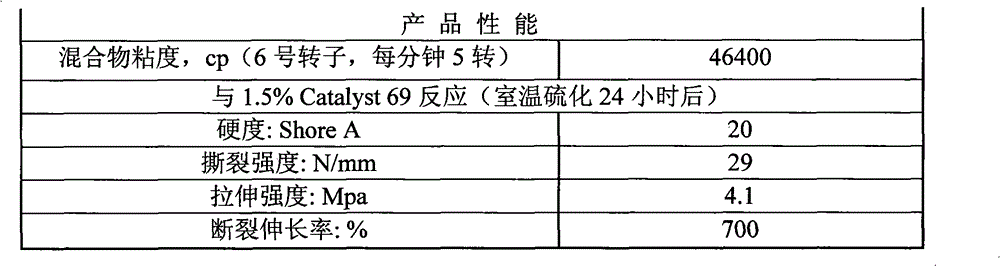

[0024] (2) Application of silica

[0025] Add 17 parts of hydroxy silicone oil with a viscosity of 14000 cp and 8.5 parts of methyl silicone oil with a viscosity of 14000 cp to 100 parts of the suspension of silicon dioxide and polysiloxane prepared above. After 69 reactions, the si...

Embodiment 2

[0029] (1) Surface treatment method of precipitated silica

[0030] Add 100 parts of 350cp methylpolysiloxane and 9 parts of hexamethyldisilazane to the stirring tank under nitrogen atmosphere, and divide 100 parts of precipitated silica into 6 times, each time according to the amount of addition The method is to add to the kettle, control the stirring time for 20 minutes each time, react at 120°C for 10 hours, then vacuumize at 150°C for 12 hours to remove small molecules, then add 100 parts of 50000cp hydroxyl silicone oil, mix and pass Three-roll mill grinding to obtain a suspension of silica and polysiloxane.

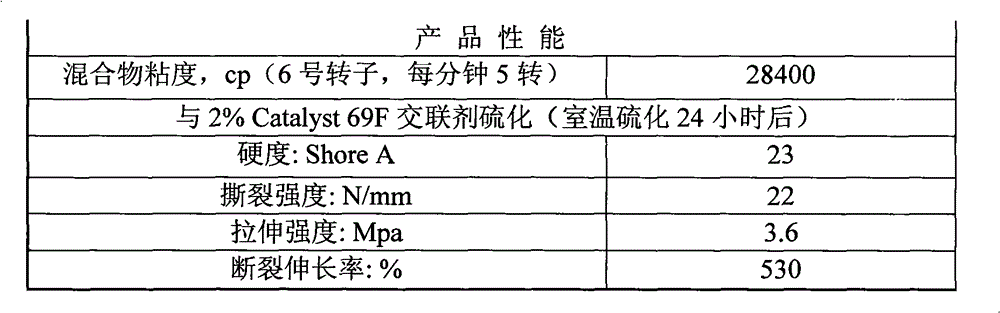

[0031] (2) Application of silica

[0032] Add 25 parts of hydroxy silicone oil with a viscosity of 3500 cp, 5 parts of methyl silicone oil of 350 cp and 9 parts of quartz powder to 100 parts of the suspension of silicon dioxide and polysiloxane prepared above, and mix well to obtain the mixture Viscosity and after reacting with vulcanizing agent Catalyst 69F, obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com