Hot steel slag cracking method

A steel slag and hot technology, applied in the direction of recycling technology, process efficiency improvement, etc., can solve the problems of unfavorable safety production, poor slag uniformity, high operating costs, etc., achieve stable and efficient recycling, stable working conditions, and eliminate explosion accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

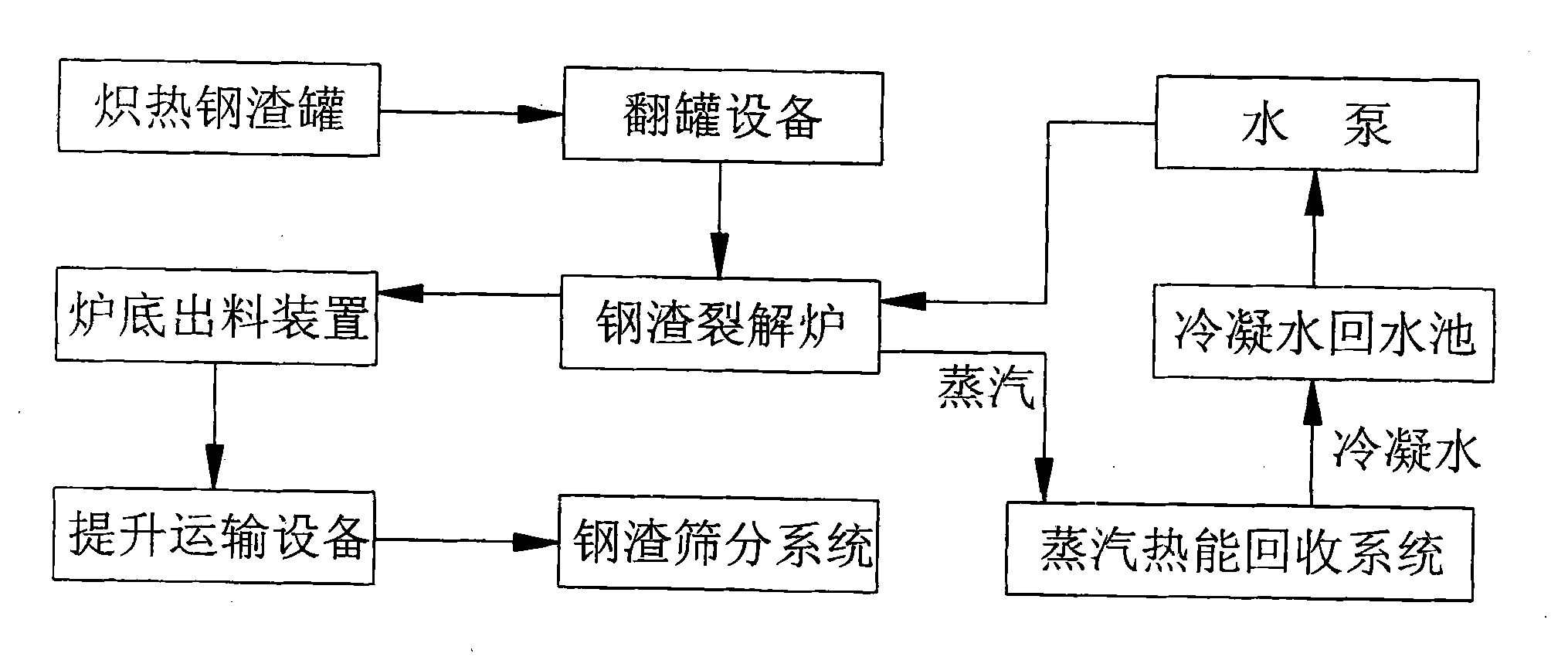

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] see figure 1 with figure 2 , a kind of red-hot steel slag cracking method, when the slag pot that the hot steel slag is housed that is transported by the steelmaking workshop arrives, at first open the I# steel slag cracking furnace discharge device 1, make the material level in the furnace drop by 1~2m, and the steel slag cracks The material of the furnace is sent into the steel slag screening equipment 10 through the lifting transport equipment 16 for particle size classification, then the I# steel slag cracking furnace feed door 5 is opened, and the red-hot steel slag is poured into the steel slag cracking by the overhead crane or automobile or train or other tank turning devices In the furnace, the charging door 5 is closed after unloading.

[0028] Open the adjustment control valve 4 of the I# steel slag cracking furnace, so that the water in the condensed wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com