Omnidirectional chassis of variable wheelbase obstacle-surmounting industrial robot

An industrial robot, variable wheelbase technology, applied in motor vehicles, transportation and packaging, etc., can solve problems such as poor omnidirectional chassis obstacle crossing ability, achieve high positioning accuracy, stable working conditions, and improve versatility and flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

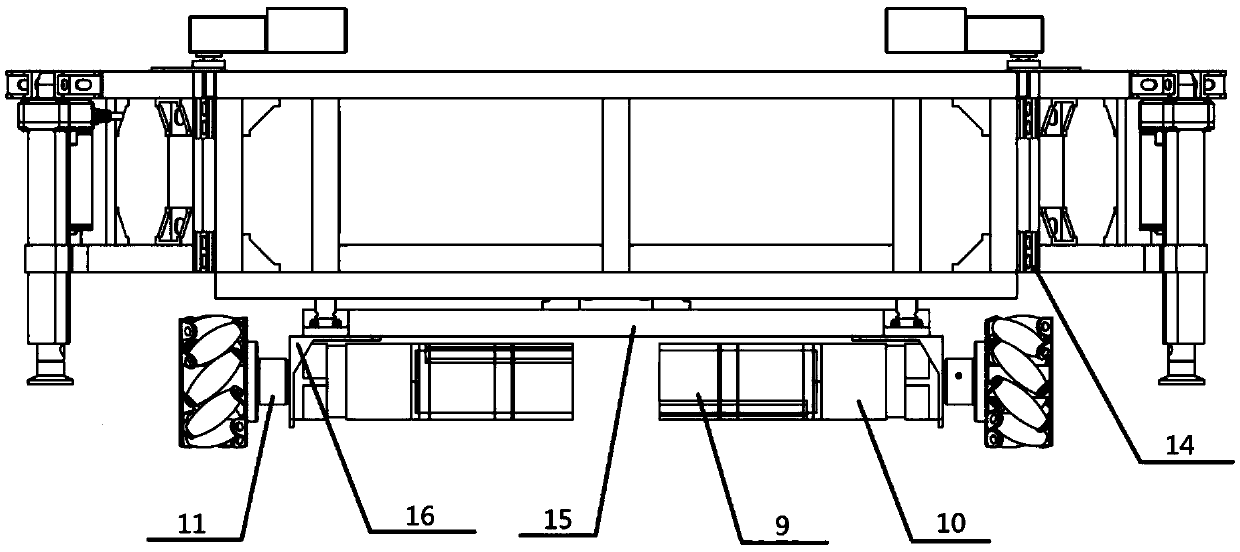

[0019] The following examples refer to Figure 1~6 .

[0020] The omni-directional chassis of the industrial robot with variable wheelbase and capable of overcoming obstacles includes an industrial robot installation base 1, a casing 2, an ultrasonic sensor 3, a vehicle frame 4, a leg bracket 5, an electric push rod 6, a steering gear 7, and a steering gear connecting rod 8 , Servo motor 9, reducer 10, flange 11, Mecanum wheel 12, pen push rod 13, hinge 14, coaxial bracket 15, motor bracket 16, slide rail 17 and slider 18.

[0021] The industrial robot installation base 1 is installed on the frame 4. The frame 4 is an aluminum profile connection structure, which is constructed by the national standard 2020 industrial aluminum profile and supporting connecting corner fittings. It is the main part of the chassis and carries the entire weight of the chassis itself and the load. . Around the vehicle frame 4 and the top installation shell 2.

[0022] Four supporting legs are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com