Method for directly preparing pigment grade chromium hemitrioxide green by using chromic hydroxide

A technology of chromium hydroxide and chromium oxide green, applied in the direction of chromium oxide/hydrate, fibrous filler, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 0.5L1mol / L sulfuric acid solution to 1L0.5mol / L sodium dichromate solution to acidify, react with 1L1mol / L formaldehyde for 3 hours, control the stirring speed to 400r / min, slowly add NaOH during the reaction to adjust the pH value, the end point pH= 6. After precipitation, the liquid is separated by filtration and washed to remove part of the Na + , to ensure Na after the filter cake is dried + <2%.

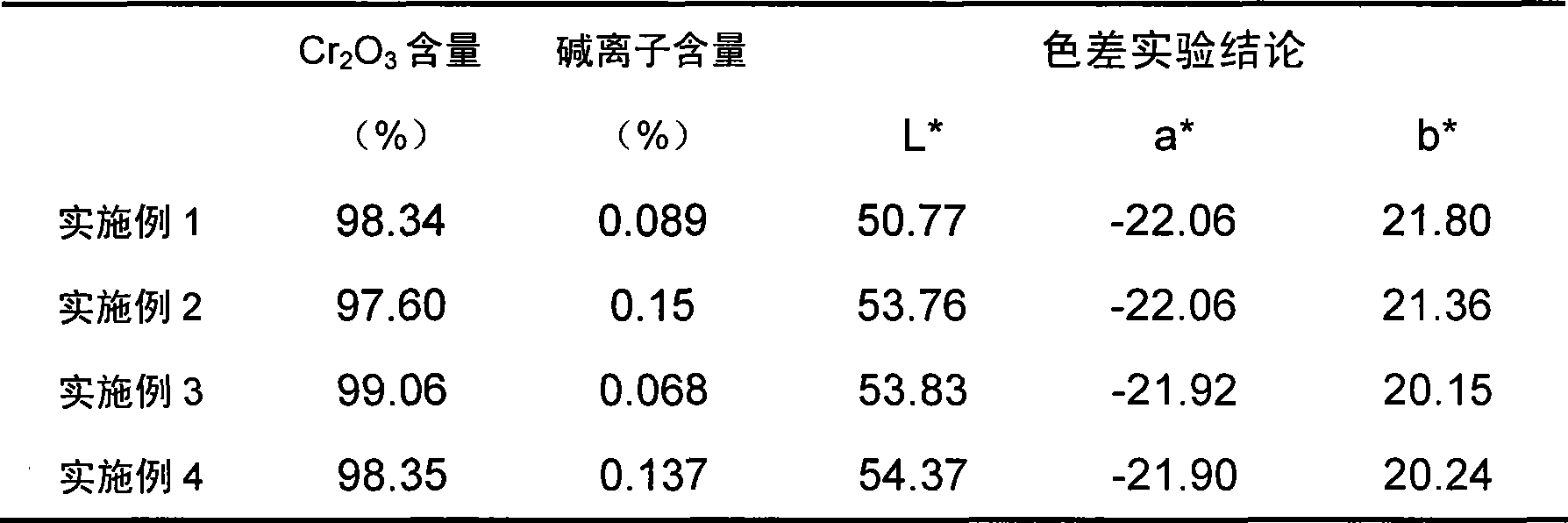

[0019] Filter cake with 1% Al 2 o 3 , ZnO, Sb 2 o 3 、H 3 PO 4 The materials are ball milled and mixed in a ball mill, and the mixed material is put into a muffle furnace for activation sintering, the sintering temperature is 900°C, and the sintering time is 2h. After sintering, the material is washed, dried, and after drying, the material is classified to obtain pigment-grade chromium oxide green. The main performance indicators are shown in the following table.

Embodiment 2

[0021] Add sodium hydroxide to 1L of 0.25mol / L chromium sulfate solution, stir and heat to 100°C for 3.5h, the pH of the solution rises gradually, and the final pH is controlled to be 7.0. Slurry filtration, washing to remove part of Na + , to ensure Na after the filter cake is dried + <2%.

[0022] Filter cake with 2% BaO, Al 2 o 3 , ZnO, Sb 2 o 3 、H 3 PO 4 , SiO 2 The materials are ball milled and mixed in a ball mill, and the mixed material is put into a muffle furnace for activation sintering, the sintering temperature is 1000°C, and the sintering time is 1h. After sintering, the material is washed, dried, and after drying, the material is classified to obtain pigment-grade chromium oxide green. The main performance indicators are shown in the following table.

Embodiment 3

[0024] Add 30g NaOH to 1L 300g / L sodium chromate solution to form sodium chromate alkaline solution, add 100g sulfur for reduction, heat to 95°C, heat and stir until Cr in the solution 6++ , to ensure Na after the filter cake is dried + <2%.

[0025] Filter cake with 2.5% Al(OH) 3 、Ba(OH) 3 、TiO 2 、H 3 PO 4 , SiO 2 The materials are ball milled and mixed in a ball mill, and the mixed material is put into a muffle furnace for activation sintering, the sintering temperature is 1100°C, and the sintering time is 1h. After sintering, the material is washed, dried, and after drying, the material is classified to obtain pigment-grade chromium oxide green. The main performance indicators are shown in the following table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com