Method for preparing high-strength carbon fiber

A carbon fiber and high-strength technology, which is applied in the field of high-strength PAN-based carbon fibers and the preparation of high-strength carbon fibers, can solve the problems of introducing defects in molecular chains, increasing production costs, and reducing mechanical properties of carbon fibers, and achieves good guiding significance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

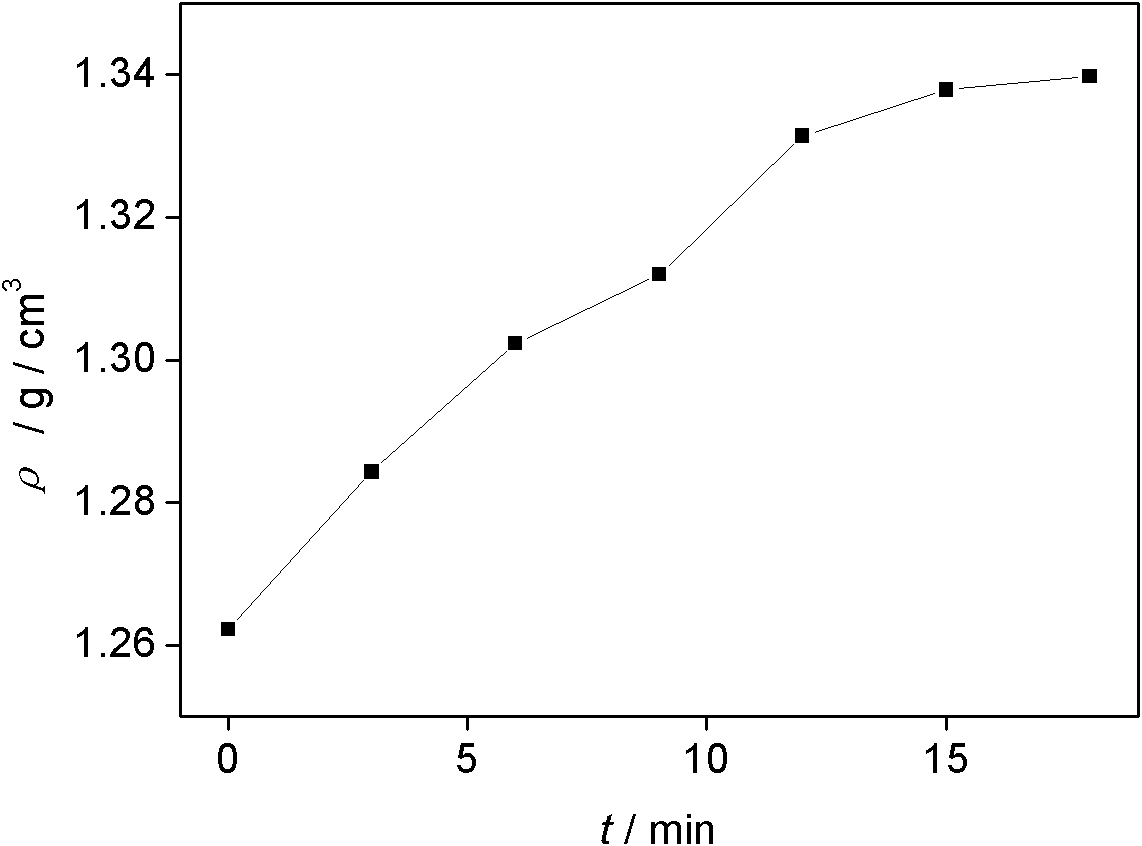

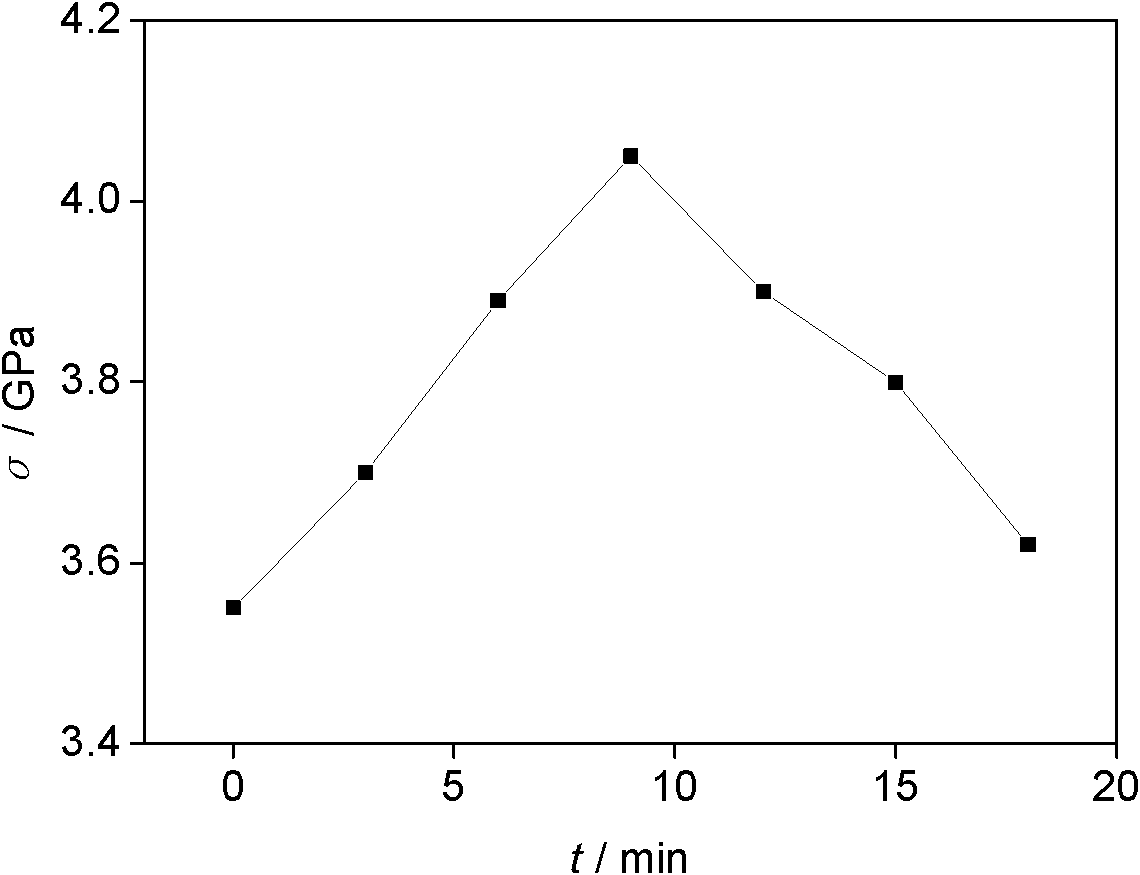

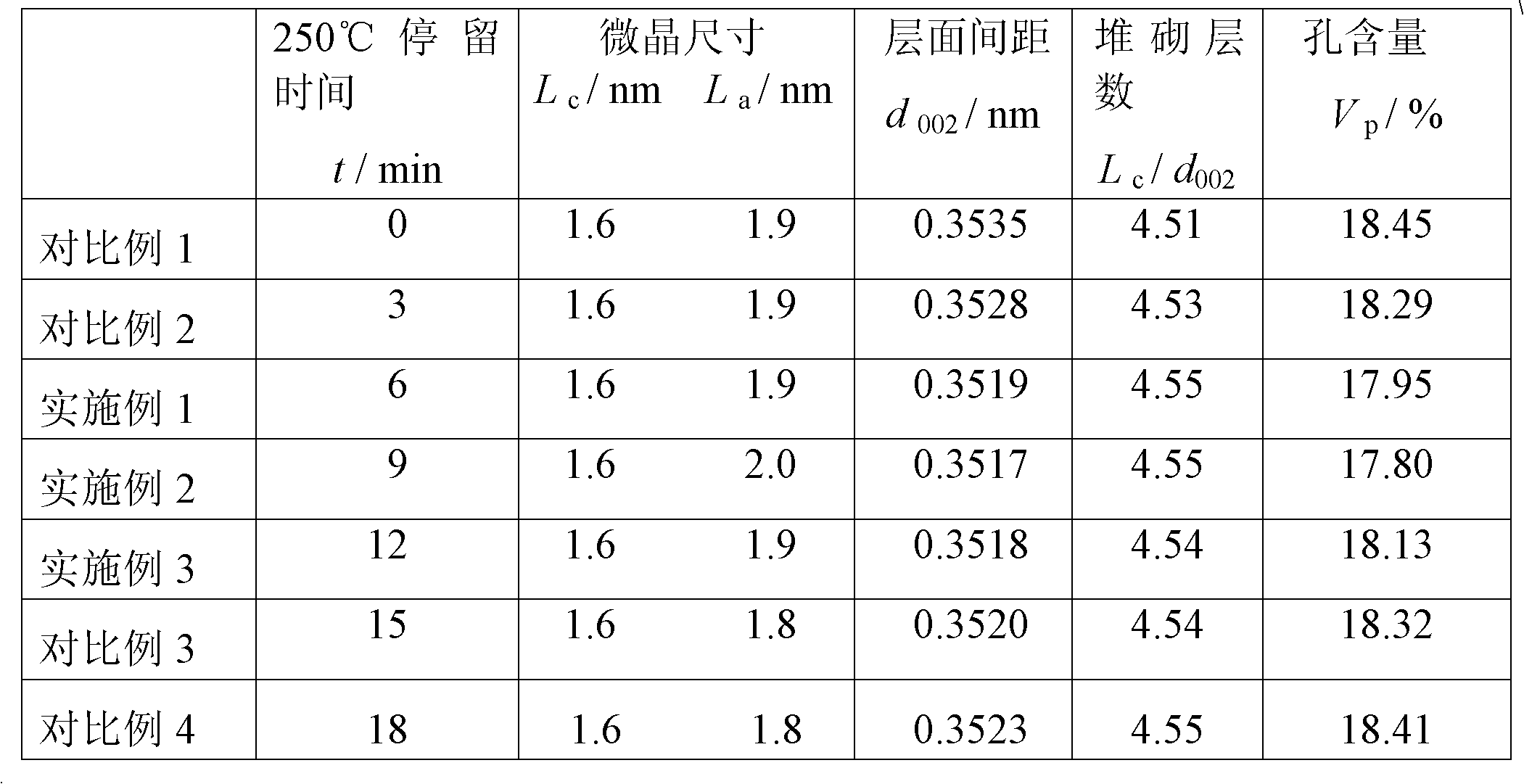

[0014] Select the commercially available British Courtaulds company of wet spinning to produce, the PAN copolymer fiber (its filament tow is 12K that contains more than 90% acrylonitrile monomer component) is: acrylonitrile (AN): Methyl acrylate (MA): itaconic acid (IA) = 92.8: 6.0: 1.2, equilibrium moisture content 0.67%), in air medium, using 210 ° C, 230 ° C, 250 ° C, 270 ° C four-stage pre-oxidation furnace Treatment, residence time is respectively: 15min, 17min, 6min, 15min, totally 53min, draft ratio is 10%, obtains pre-oxidized fiber, the volume density of the pre-oxidized fiber after heat treatment in 250 ℃ temperature zone is shown in Table 2, pre-oxidized Under the protection of nitrogen, the fiber is subjected to low-temperature carbonization at 350°C, 480°C, 580°C, and 680°C. The residence time in each temperature zone is 1min, a total of 4min. Apply +4% draft ratio; apply at 1250°C -3% draw ratio, carbonization at high temperature for 2 minutes, to obtain carbon f...

Embodiment 2

[0016] The PAN copolymer fiber used and other operation steps are all the same as example 1. Among them, the pre-oxidation gradient temperature is 210°C, 230°C, 250°C, 270°C four-stage pre-oxidation furnace treatment, the residence time is 15min, 17min, 9min, 15min, a total of 56min, and the draft ratio is 10%. fiber. Under the protection of nitrogen, the pre-oxidized fiber was subjected to low-temperature carbonization at 350°C, 480°C, 580°C, and 680°C. The residence time in each temperature zone was 0.8min, a total of 3.6min, and a +5% draft ratio was applied; A draft ratio of -2% was applied at a temperature of 1300°C, and carbonized at a high temperature for 2.5 minutes to obtain carbon fibers. The results are shown in Table 1 and Table 2.

Embodiment 3

[0018] The PAN copolymer fiber used and other operation steps are all the same as example 1. Among them, the pre-oxidation gradient temperature is 210°C, 230°C, 250°C, and 270°C for four-stage pre-oxidation furnace treatment, the residence time is 15min, 17min, 12min, and 15min respectively, a total of 59min, and the draft ratio is 10%. fiber. Under the protection of nitrogen, the pre-oxidized fiber was carbonized at a low temperature at 350°C, 480°C, 580°C, and 680°C. The residence time in each temperature zone was 0.7min, a total of 2.8min, and a +6% draft ratio was applied; Apply a draft ratio of -3% at a temperature of 1350°C, and carbonize at a high temperature for 3 minutes to obtain carbon fibers. The results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com