Industrial preparation of calcium carbonate nano bead string

A calcium carbonate, nano technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve problems such as unfavorable industrial production, complicated process operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

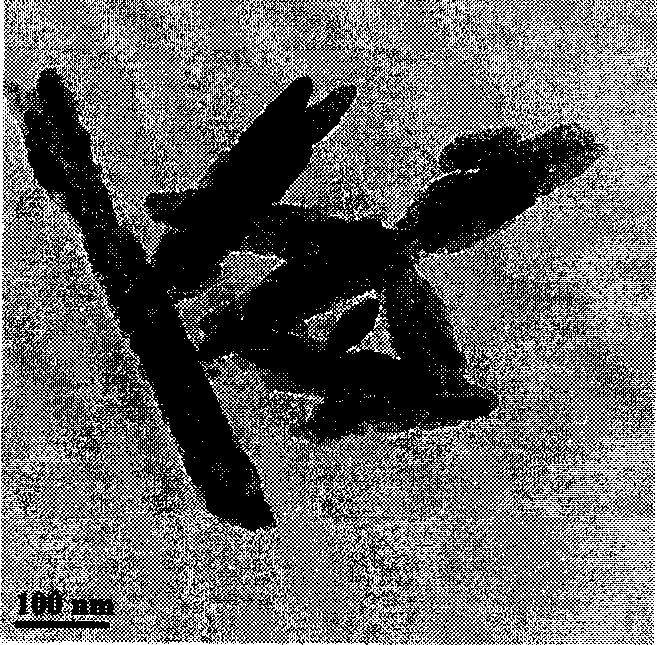

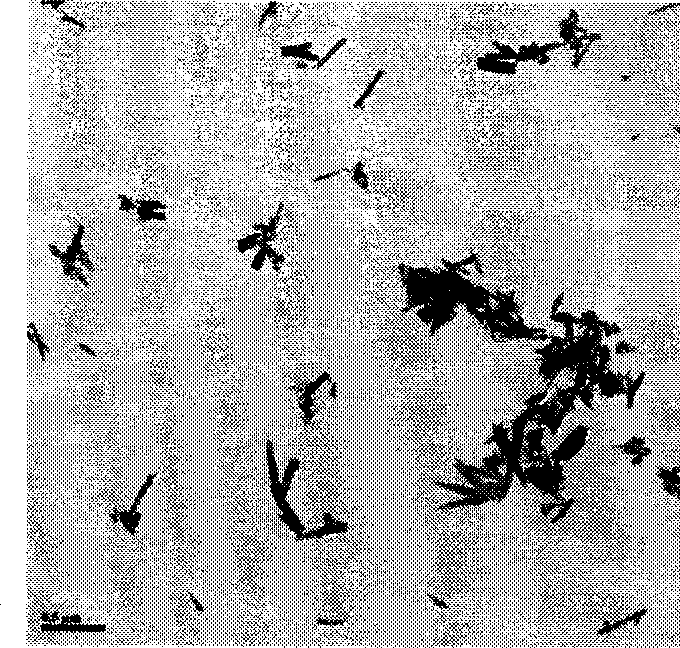

Image

Examples

Embodiment 1

[0019] CaCO 3 The content is 96%, MgCO 3 The natural limestone with a content of 0.7% is crushed and calcined, digested with hot water at 60°C, passed through a 250-mesh sieve, and diluted with water to prepare a refined calcium hydroxide feed liquid. The refined calcium hydroxide feed liquid is The concentration is 80 g / l.

[0020] to 20m 3 Add 14m to the reactor 3 Concentration above-mentioned calcium hydroxide slurry, then add 10 kilograms of sodium pyrophosphate, pass into the kiln gas that contains carbon dioxide and be 25% (volume concentration) and carry out carbonization, the flow rate of kiln gas is controlled at 650m 3 / h, the reaction temperature of the whole carbonization process shall not be higher than 40°C. When the carbonization reaches 8 to a pH value, add 8 kilograms of sodium lauryl sulfate and continue the carbonization until the reaction ends to obtain a uniformly dispersed calcium carbonate slurry for use, and the whole reaction is no more than 3 hour...

Embodiment 2

[0023] CaCO 3 The content is 96%, MgCO 3 The natural limestone content is 0.7%. After crushing and calcining, add hot water at 70°C for digestion, pass through a 250-mesh sieve, and dilute with water to prepare a refined calcium hydroxide feed liquid. The refined calcium hydroxide feed liquid is The concentration is 70 g / l.

[0024] to 20m 3 Add 12m to the reactor 3 Above-mentioned calcium hydroxide slurry, then add 20 kilograms of sodium pyrophosphates, pass into the kiln gas that contains carbon dioxide and be 25% (volume concentration) and carry out carbonization, the flow rate of kiln gas is controlled at 800m 3 / h, the reaction temperature of the whole carbonization process shall not be higher than 40°C. Carbon dioxide is passed through to carbonization until the end of the reaction to obtain a uniformly dispersed calcium carbonate slurry for use, and the whole reaction is no more than 3 hours.

[0025] The calcium carbonate slurry is filtered, dried at 150°C, and cr...

Embodiment 3

[0027] CaCO 3 The content is 96%, MgCO 3 The natural limestone with a content of 0.7% is crushed and calcined, digested with hot water at 60°C, passed through a 250-mesh sieve, and diluted with water to prepare a refined calcium hydroxide feed liquid. The refined calcium hydroxide feed liquid is The concentration is 80 g / l.

[0028] to 20m 3 Add 14m to the reactor 3 Above-mentioned calcium hydroxide slurry, add 40 kilograms of sodium pyrophosphates, pass into the kiln gas that contains carbon dioxide and be 40% (volume concentration) and carry out carbonization, the flow rate of kiln gas is controlled at 800m 3 / h, the reaction temperature of the whole carbonization process shall not be higher than 40°C. When the carbonization reaches 8 to the pH value, add 5 kilograms of sodium dodecylsulfonate and continue the carbonization to the end of the reaction to obtain a uniformly dispersed calcium carbonate slurry for use, and the whole reaction is no more than 3 hours.

[0029...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Bet specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com