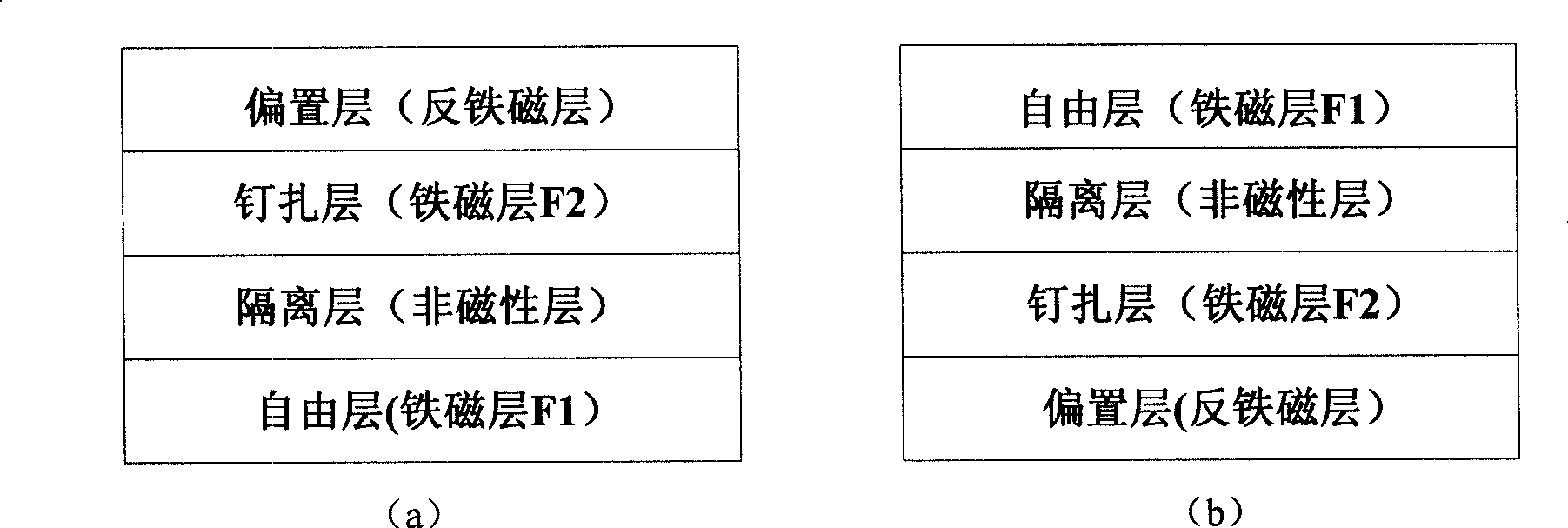

Double exchange bias field type spinning valve

A bias field and double-exchange technology, which is applied in spin-exchange-coupled multilayer films, measuring devices, and magnetic field-controlled resistors, can solve the problem of degraded giant magnetoresistance performance, spin-valve multilayer interlayer interactions, etc. Diffusion and other issues, to achieve good film stability and giant magnetoresistance performance, improve stability, and widen the effect of high resistance area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

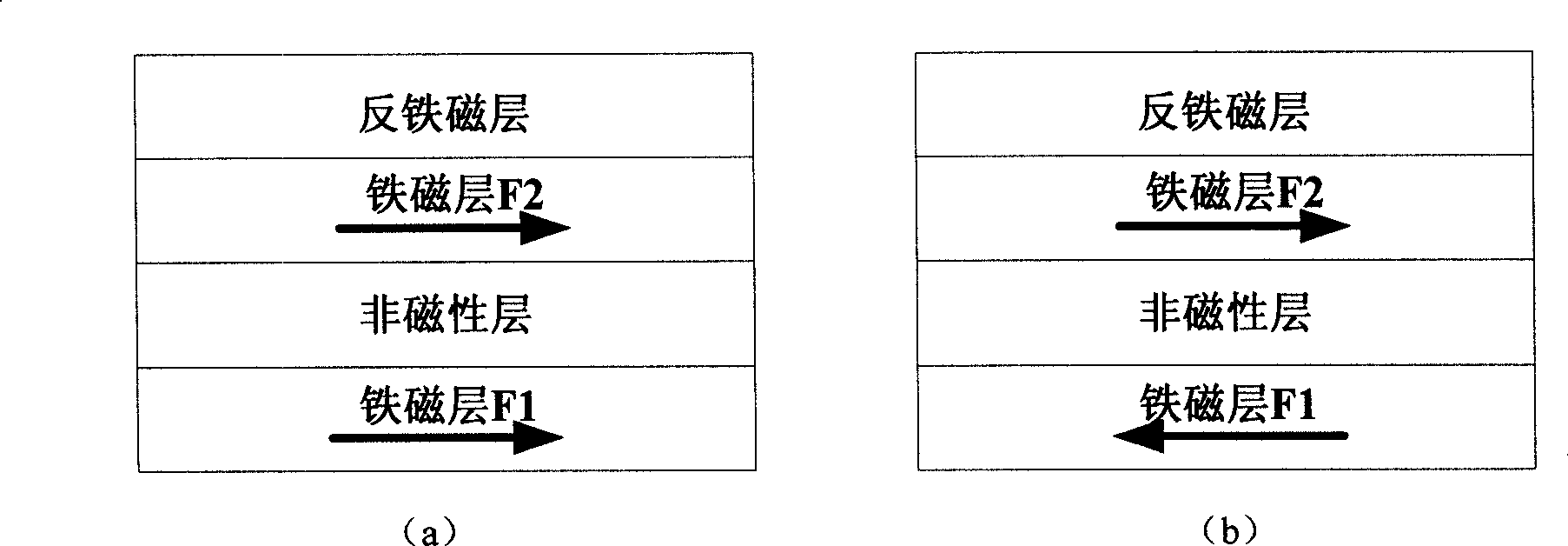

Method used

Image

Examples

Embodiment Construction

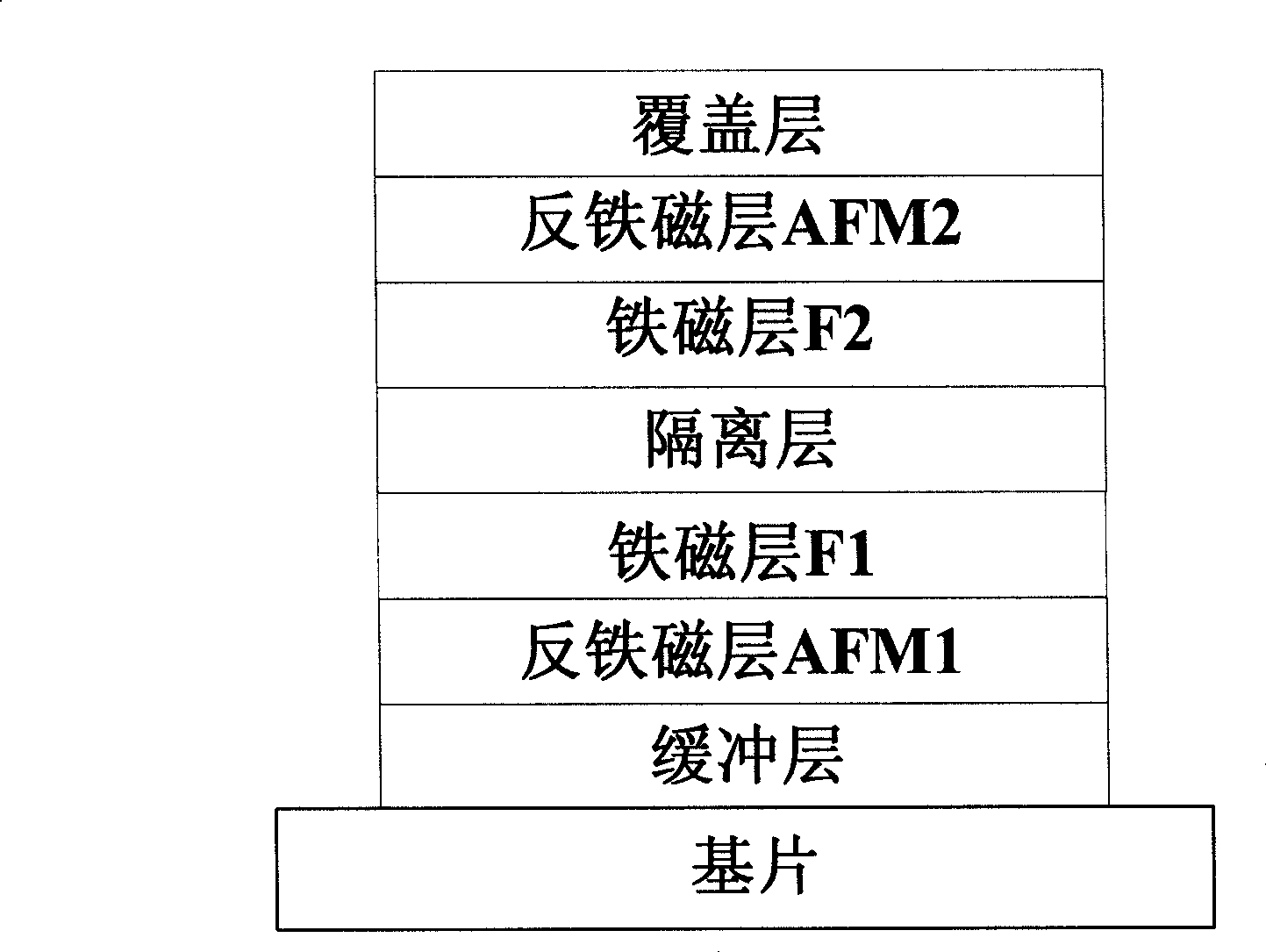

[0018] Preparation of Ta(10nm) / FeMn(15nm) / NiFe(6nm) / Cu(4nm) / NiFe(12nm) / FeMn(15nm) / Ta(5nm) on Si substrate by computer-controlled four-target magnetron sputtering equipment Double exchange bias field spin valve. A pair of permanent magnets are used to provide a 300Oe deposition magnetic field along the film surface during deposition. After the Ta(10nm) / FeMn(15nm) / NiFe(6nm) / Cu(4nm) multilayer film is deposited, the permanent magnet The axis of the surface is rotated 180 degrees, so that the direction of the magnetic field is antiparallel to the direction of the magnetic field during the initial deposition, and the NiFe(12nm) / FeMn(15nm) / Ta(5nm) multilayer film is sputtered, and the double exchange bias field spin is finally completed. Valve preparation. For comparison, using the same sputtering conditions, a Ta(10nm) / NiFe(6nm) / Cu(4nm) / NiFe(12nm) / FeMn(15nm) / Ta(5nm) top spin valve was prepared with a four-probe The giant magnetoresistance effect of the sample was tested by the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com