Method for synthesizing diamino formic ether

A technology of diurethane and carbamate, which is applied in the field of catalyzing carbamate and alkyl or aryl diamine to synthesize corresponding dicarbamate, which can solve unfavorable industrial scale-up, high reaction temperature, side effects There are many products, etc., to achieve the effect of good reusability, good economy, and easy separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

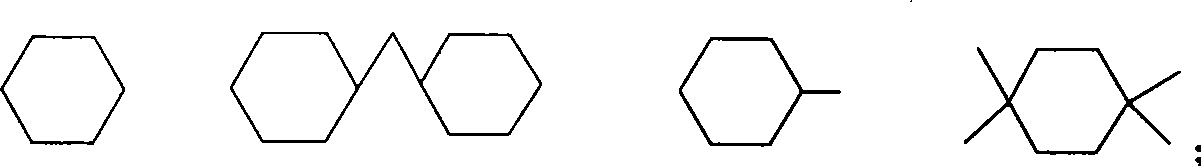

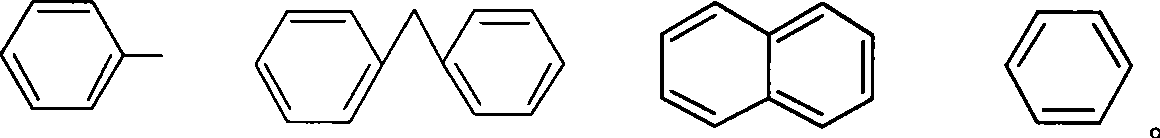

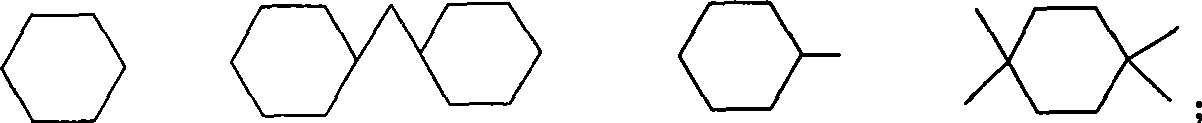

Method used

Image

Examples

Embodiment 1

[0032] In a 2L autoclave, add 174.5g butyl carbamate (BC) and 58g 1,6-hexamethylenediamine (HDA), add Zn(OAc) 2 3 g, the solvent is butanol, and the reaction is completed after 5 hours at 180° C., the reaction pressure is 1.5 MPa, and 500 rpm. After the product was cooled to room temperature, samples were taken to obtain sample 1 of a colorless clear liquid and part of the catalyst, and part of the catalyst was recovered by filtration. Take 1-2ml sample 1 and dissolve it in 2-3ml chloroform for chromatographic analysis. Then at 80°C and 100mmHg, the butanol in sample 1 was recovered by distillation, and the residue after distillation was cooled to room temperature and 200ml of ether was added to obtain the target product 1,6-butyl-hexanedicarbamate (BHDC), part of the catalyst, The monoester (hexamethylene-1-amino-6-carbamate butyl) and a small amount of butylated product were precipitated, and then subjected to suction filtration to obtain a mixture of BHDC, part of the cat...

Embodiment 2

[0035]In a 2L autoclave, add 174.5g butyl carbamate (BC) and 100g 4,4-diphenylmethanediamine (MDA), add Pb(OAc) 2 3 g, the solvent is butanol, and the reaction is completed after 6 hours at 280° C., the reaction pressure is 1.5 MPa, and 450 rpm. After the product was cooled to room temperature, samples were taken to obtain a light yellow clear liquid and a sample 1 of a part of the catalyst, and part of the catalyst was recovered by filtration. Take 1-2ml sample 1 and dissolve it in 2-3ml chloroform for chromatographic analysis. Then at 80°C, under 100mmHg, the butanol in sample 1 was recovered by distillation, and the residue after the distillation was cooled to room temperature and 200ml of ether was added to obtain the target product 4,4-diphenylmethanedicarbamate butyl ester (BMDC), Part of the catalyst, monoester (butyl diphenylmethane-4-amino-4-carbamate) and a small amount of butylated product were precipitated, and then suction filtration was performed to obtain a mi...

Embodiment 3

[0037] In a 2L autoclave, add 225g methyl carbamate (MC) and 122g 2,6-toluenediamine (MDA), add SnCl 2 3 g, the solvent is methanol, at 160° C., the reaction pressure is 1.5 MPa and 600 rpm, the reaction is completed after 5 hours. After the product was cooled to room temperature, samples were taken to obtain sample 1 of a colorless clear liquid and part of the catalyst, and part of the catalyst was recovered by filtration. Take 1-2ml sample 1 and dissolve it in 2-3ml chloroform for chromatographic analysis. Then, at 40°C and 100mmHg, the methanol in sample 1 was recovered by distillation, and the residue after distillation was cooled to room temperature and 200ml of ether was added to obtain the target product 2,6-toluene dicarbamate (MTDC), part of the catalyst, mono Esters (methyl toluene-2 / 6-amino-6 / 2-carbamate) and a small amount of methylated products were precipitated, and then filtered with suction to obtain a mixture of MTDC, part of the catalyst and a small amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com