Eccentric self-locking anchor nut

A pallet nut and self-locking technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems such as the decline of the locking ability of ordinary oval self-locking pallet nuts, and achieve good locking performance and repeated use. The effect of good sex and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

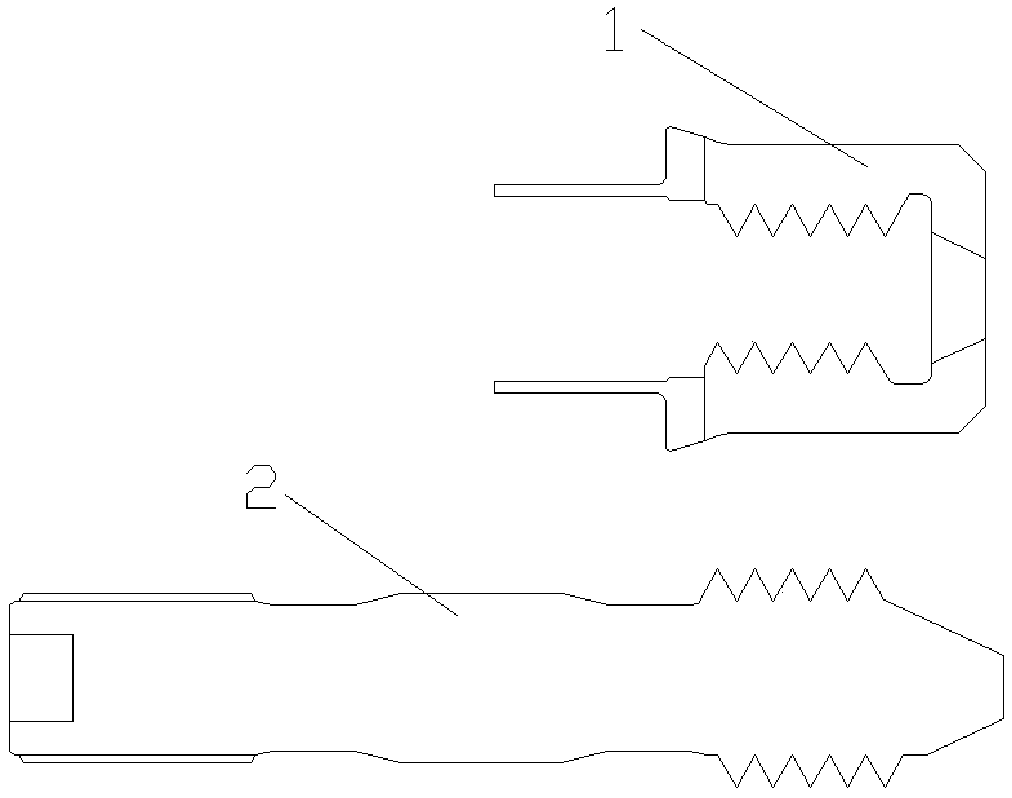

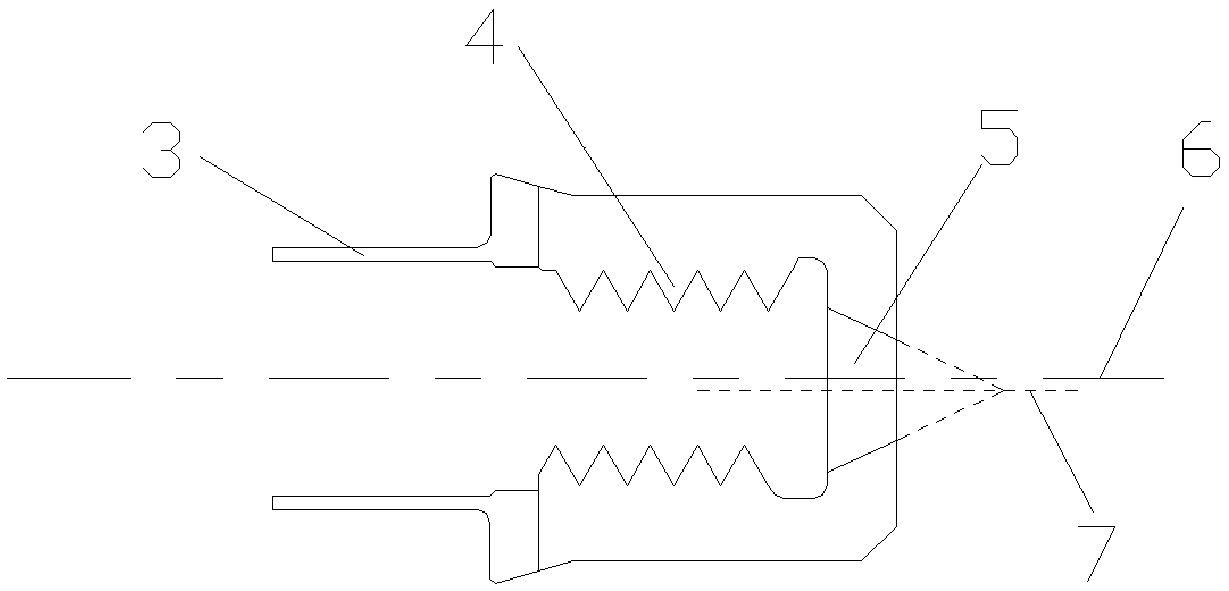

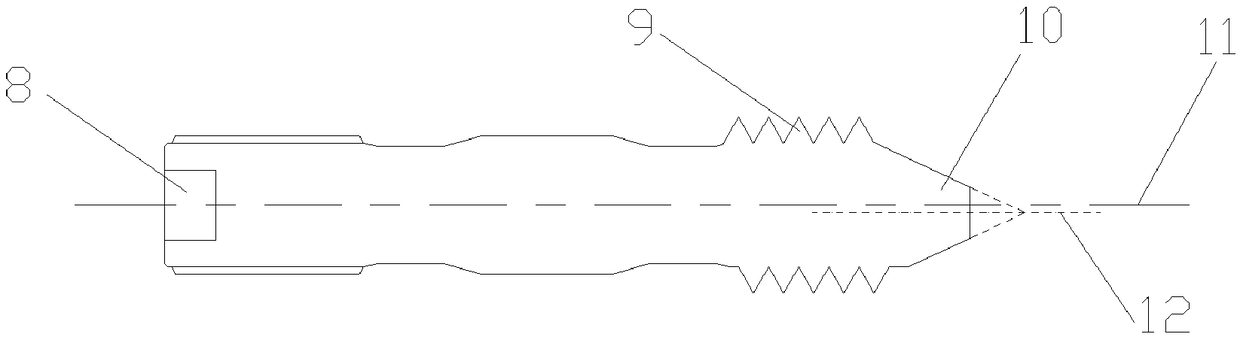

[0013] See attached Figure 1-3 , what the present invention creates and designs is a kind of eccentric self-locking pallet nut, and nut and stud (bolt) will combine design and just can reach the purpose of eccentric locking. The structure of the bracket nut and stud is as follows: figure 1 shown.

[0014] The structure of the present invention is composed of a supporting plate nut 1 and a stud 2, and the locking structure is an eccentric taper hole 5 at the end of the nut and an eccentric taper head 10 at the end of the stud. After the nut and the stud are screwed together, the centerline 7 coincides with the centerline 12, and the surface of the tapered hole 5 and the surface of the tapered head 10 fit together just right. If you want to loosen the nut and the stud, since the center of rotation is the center line 6 (or 11), the center line 7 will be separated from the center line 12, which will cause the mutual interference between the taper hole 5 and the taper head 10, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com