Phosphorus nitrogen boron lumber combustion inhibitor

A flame retardant, phosphorus nitrogen boron technology, applied in the direction of wood impregnation, wood impregnation, wood processing appliances, etc., can solve problems such as deformation, paint peeling, cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

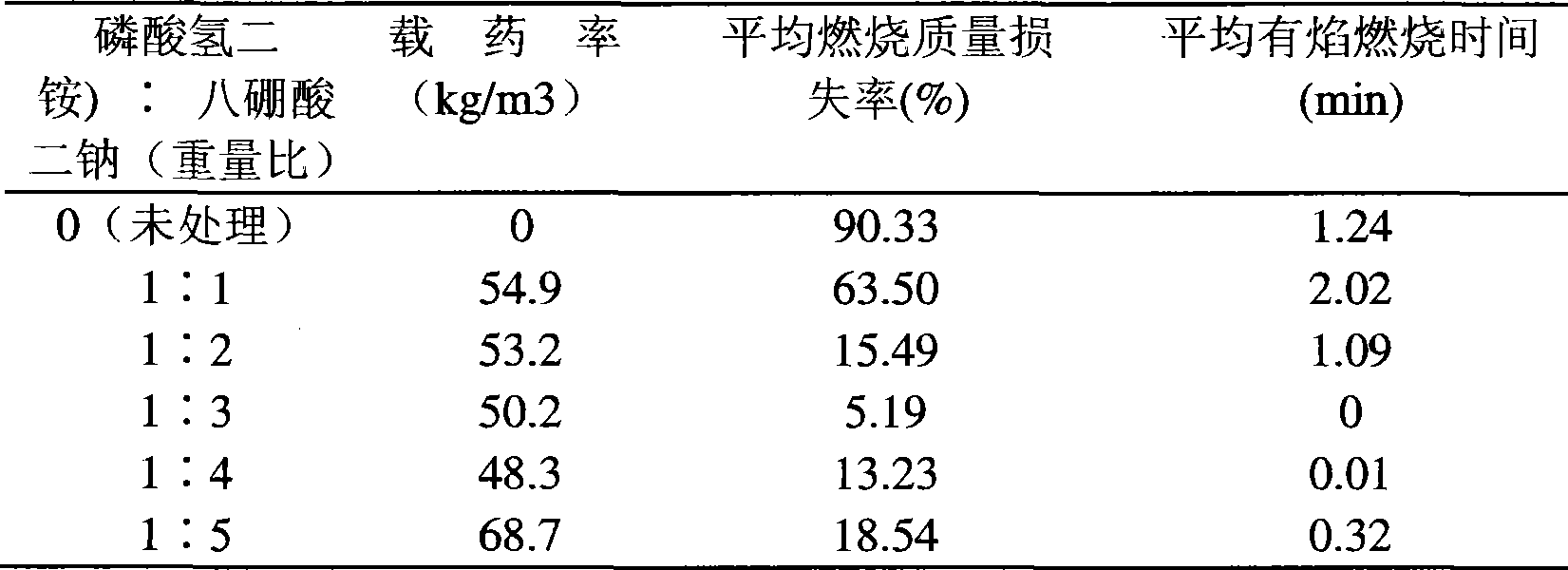

Embodiment 1

[0072] A phosphorus-nitrogen-boron wood flame retardant, the range of the name and weight percentage of each component is:

[0073] Disodium octaborate 80%

[0074] Diammonium Phosphate 20%

[0075] When processing wood, the above-mentioned phosphorus, nitrogen and boron wood fire retardant is dissolved in water, and the concentration of the phosphorus, nitrogen and boron wood fire retardant solution is 10%, and the average flame burning time (min) of the treated wood is 0, and the obtained Good flame retardant effect.

Embodiment 2

[0077] A phosphorus-nitrogen-boron wood flame retardant, the range of the name and weight percentage of each component is:

[0078] Disodium octaborate 70%

[0079] Water-soluble ammonium polyphosphate 30%

[0080] When processing wood, the above-mentioned phosphorus, nitrogen and boron wood fire retardant is dissolved in water, and the concentration of the phosphorus, nitrogen and boron wood fire retardant solution is 20%, and the average flame burning time (min) of the treated wood is 0, and the obtained Good flame retardant effect.

Embodiment 3

[0082] A phosphorus-nitrogen-boron wood flame retardant, the range of the name and weight percentage of each component is:

[0083] Disodium octaborate 75%

[0084] A1 25%

[0085] Among them, A1 is made by mixing ammonium dihydrogen phosphate and water-soluble ammonium polyphosphate according to the weight ratio of ammonium dihydrogen phosphate: water-soluble ammonium polyphosphate = 1:1.

[0086] When processing wood, the above-mentioned phosphorus, nitrogen and boron wood fire retardant is dissolved in water, and the concentration of the phosphorus, nitrogen and boron wood fire retardant solution is 20%, and the average flame burning time (min) of the treated wood is 0, and the obtained Good flame retardant effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com