Strong cation exchange polymer integral column capillary tube and its production method and use

A strong cation exchange and capillary technology, which is applied in the field of strong cationic polymer monolithic column capillary and its preparation, can solve the problems of inability to meet detection technical requirements, good reproducibility, long time consumption, etc., and achieve reliable and high-sensitivity analysis methods, extraction The effect of large capacity and high enrichment factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Preparation of 2-acrylamide-2-methyl-1-propanesulfonic acid-ethylene glycol dimethacrylate polymer monolithic column capillary

[0021] Functional monomer: 10 mg of 2-acrylamide-2-methyl-1-propanesulfonic acid, cross-linking agent: 70 μL of ethylene glycol dimethacrylate, porogen: 220 μL of N,N-dimethylformamide and 110mg of polyethylene glycol 6000, initiator: 1mg of azobisisobutyronitrile, mixed and stirred evenly at room temperature, poured into a vinyl-modified quartz capillary, sealed, and initiated the polymerization reaction at 60°C for 12 hours, and the polymerization reaction was completed Finally, fully wash the capillary with acetonitrile to remove unreacted monomers, cross-linking agents and porogens to obtain 2-acrylamide-2-methyl-1-propanesulfonic acid-ethylene glycol dimethacrylate polymer as a whole Column capillary.

Embodiment 2

[0022] Example 2: Preparation of 2-acrylamide-2-methyl-1-propanesulfonic acid-ethylene glycol dimethacrylate polymer monolithic column capillary

[0023] Functional monomer: 15 mg of 2-acrylamide-2-methyl-1-propanesulfonic acid, cross-linking agent: 65 μL of ethylene glycol dimethacrylate, porogen: 200 μL of N,N-dimethylformamide and 100mg of polyethylene glycol 4000, initiator: 2mg of azobisisobutyronitrile, mixed and stirred evenly at room temperature, ultrasonically oscillated for 10 minutes to remove oxygen, poured into a vinyl-modified quartz capillary, sealed, and initiated at 65°C After 14 hours of polymerization reaction, after the completion of the polymerization reaction, fully wash the capillary with methanol to remove unreacted monomers, cross-linking agents and porogens to obtain 2-acrylamide-2-methyl-1-propanesulfonic acid-ethylene glycol Dimethacrylate polymer monolithic column capillary.

Embodiment 3

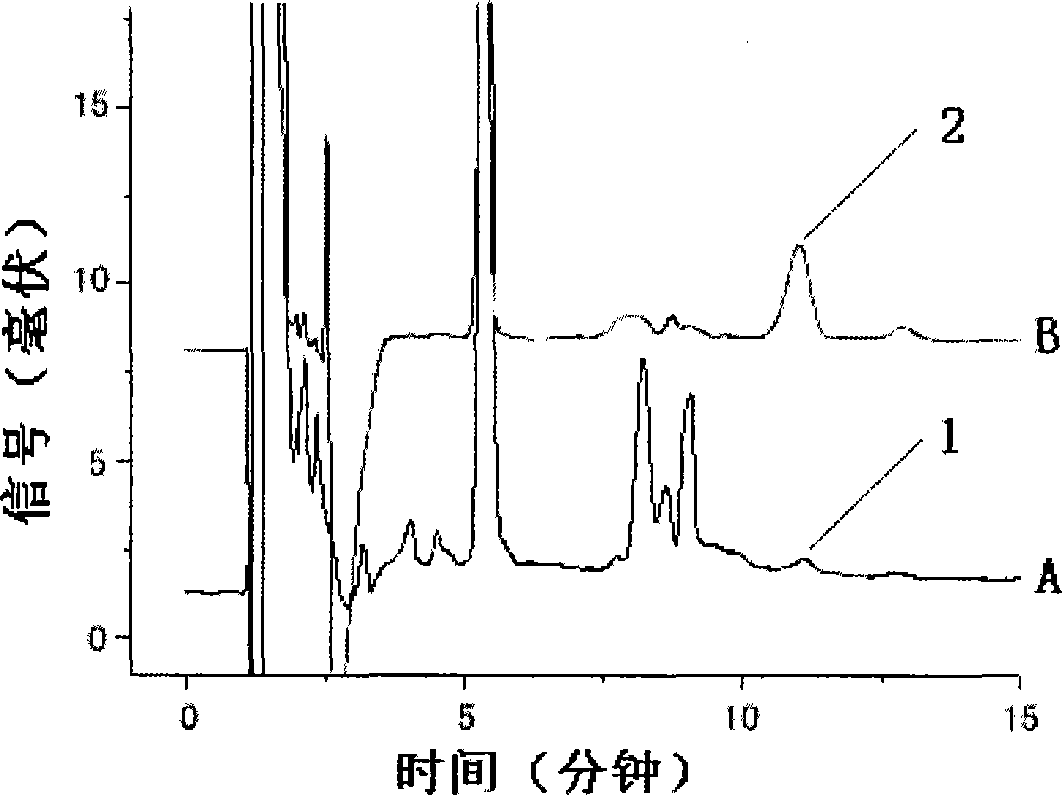

[0024] Example 3: The detection of melamine in milk powder samples with the monolithic column capillary prepared in Example 1 as the extraction medium

[0025] The polymer monolithic column microextraction device provided by the patent number ZL200520095986.1 was used to analyze the melamine in the milk powder sample by using the high performance liquid chromatography analysis method.

[0026] Extraction and chromatographic analysis conditions: the extraction flow rate is 0.06mL / min, and the extraction time is 5min. The analytical column was an Agilent Eclipse XDB-C8 column (150mm×4.6mm i.d., 5μm), and the mobile phase was a buffer solution (pH3.0) containing 10mM citric acid and 5mM sodium octanesulfonate and methanol at a ratio of 80:20 (v / v) Mixing, flow rate 1 mL / min. The detection condition is an ultraviolet detector, and the detection wavelength is 240nm.

[0027] Milk powder sample analysis: Collect milk powder samples, add 1% trichloroacetic acid solution and 22g / L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com