Plate transport apparatus

A technology for plates and equipment, which is applied in the field of plate unloading equipment, can solve problems such as insufficient and unable to offset the moving time, and achieve the effect of improving the efficiency of unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

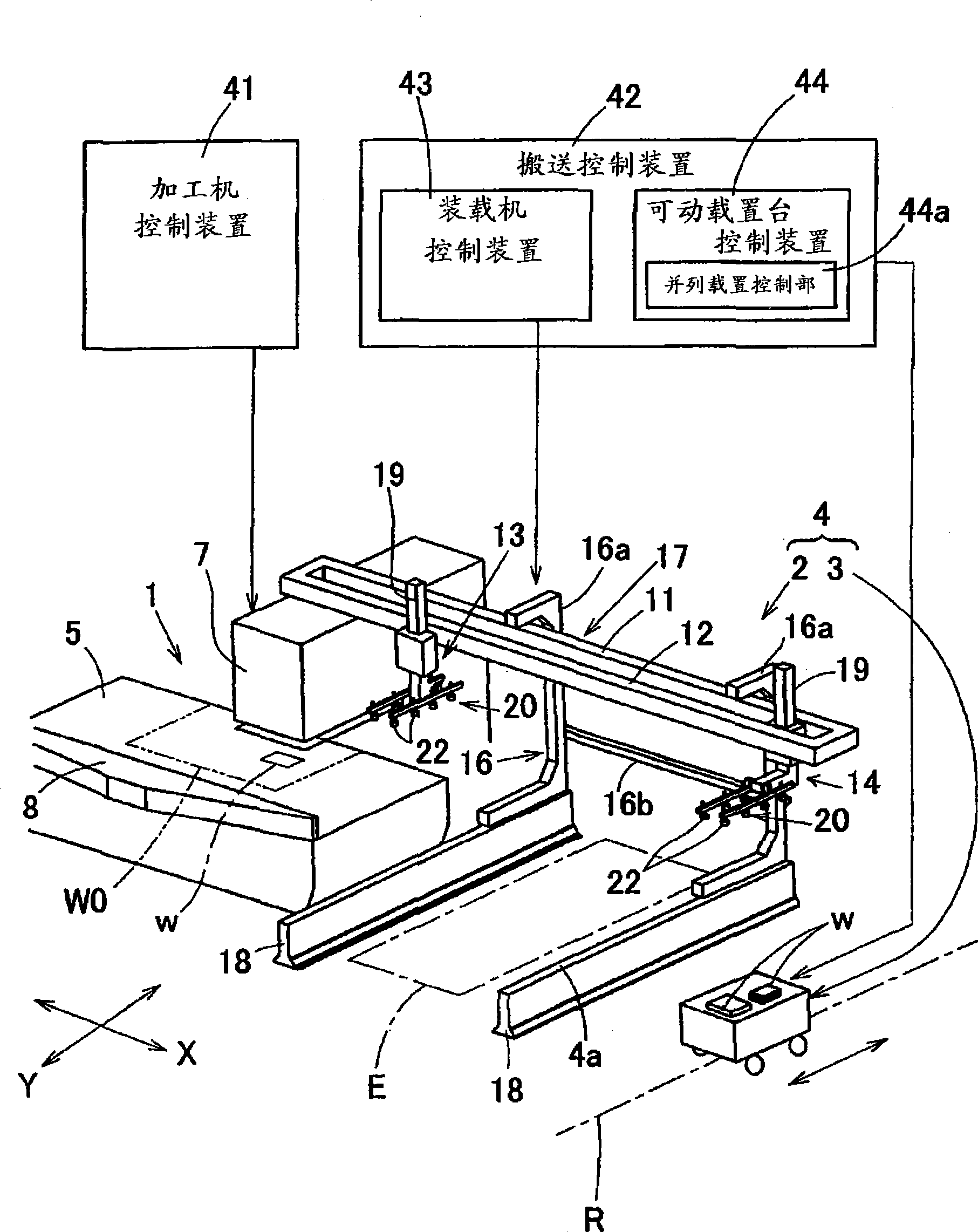

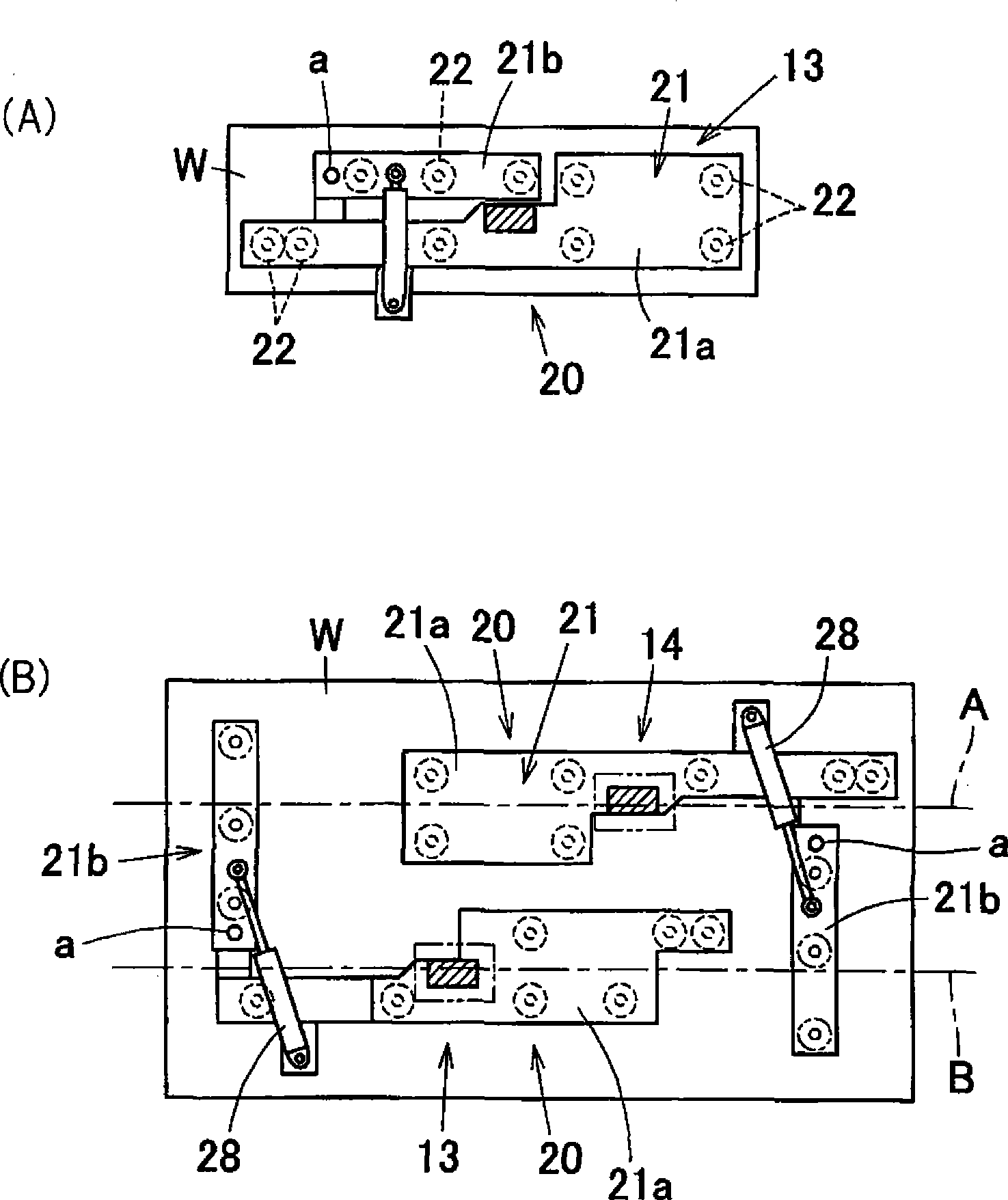

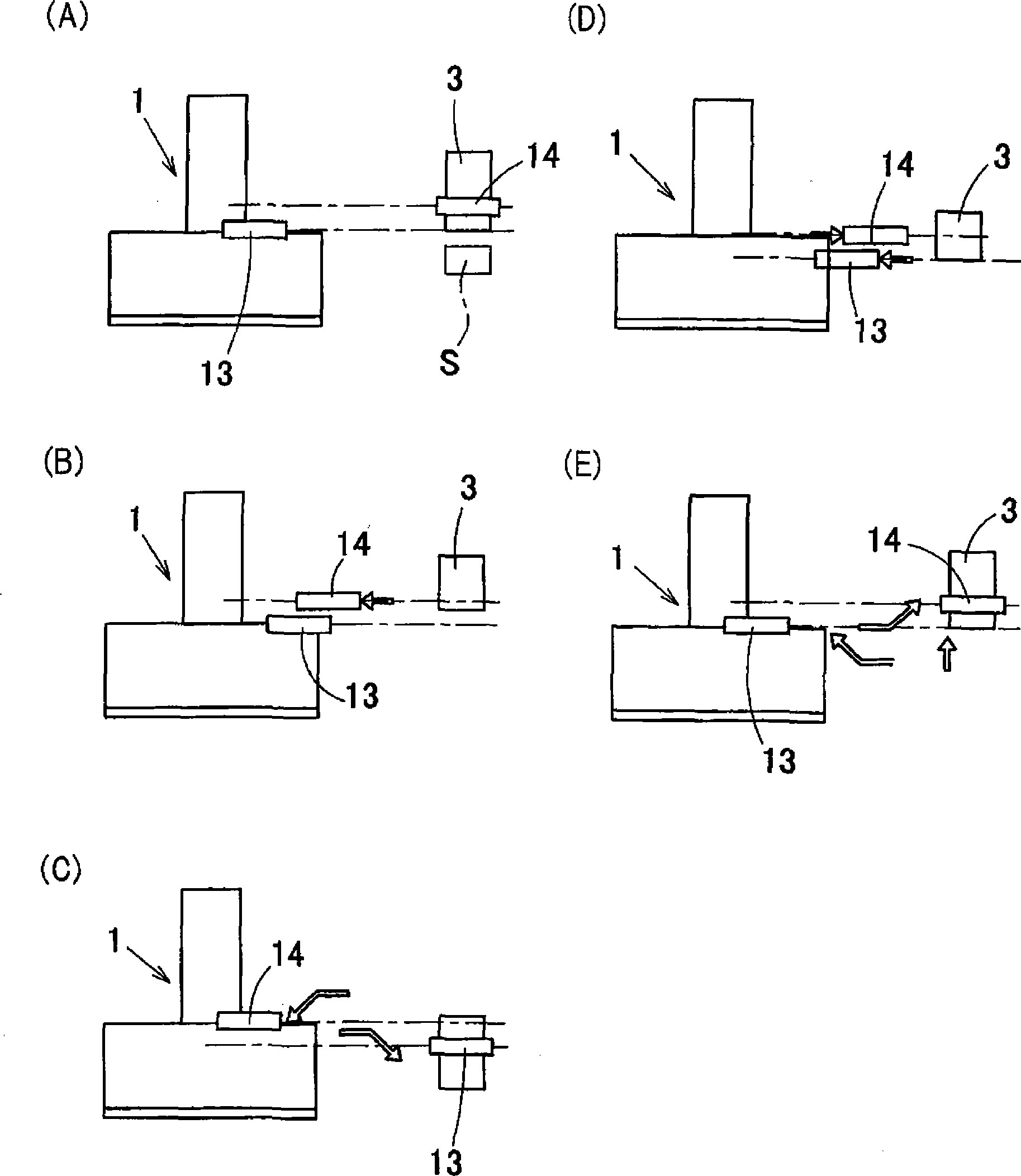

[0026] Below, combine Figure 1 to Figure 3 , the first embodiment of the present invention will be described. figure 1 Indicates sheet material processing equipment equipped with the sheet material unloading facility. This sheet material processing facility has a sheet material processing machine 1 and a sheet material unloading facility 4 composed of a sheet material unloading device 2 and a movable mounting table 3 . This work sheet processing facility also includes a work sheet carrying device (not shown) for carrying a work sheet W to be a raw material into the work sheet processing machine 1 , but description of the work sheet carrying device is omitted.

[0027] The sheet metal processing machine 1 has a function of punching a raw material sheet W on the table 5 into a plurality of product sheets w, etc., and cutting them out, and is constituted by a punching machine or a laser processing machine. In this example, the sheet material processing machine 1 is a press mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com