Micropore ceramics and method for sustained-release of medicament or biological preparation and use thereof

A technology of microporous ceramics and biological preparations, applied in the field of microporous ceramics, can solve the problems of high price, large drug damage, affecting the activity of biological preparations, etc., and achieve the effect of reducing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

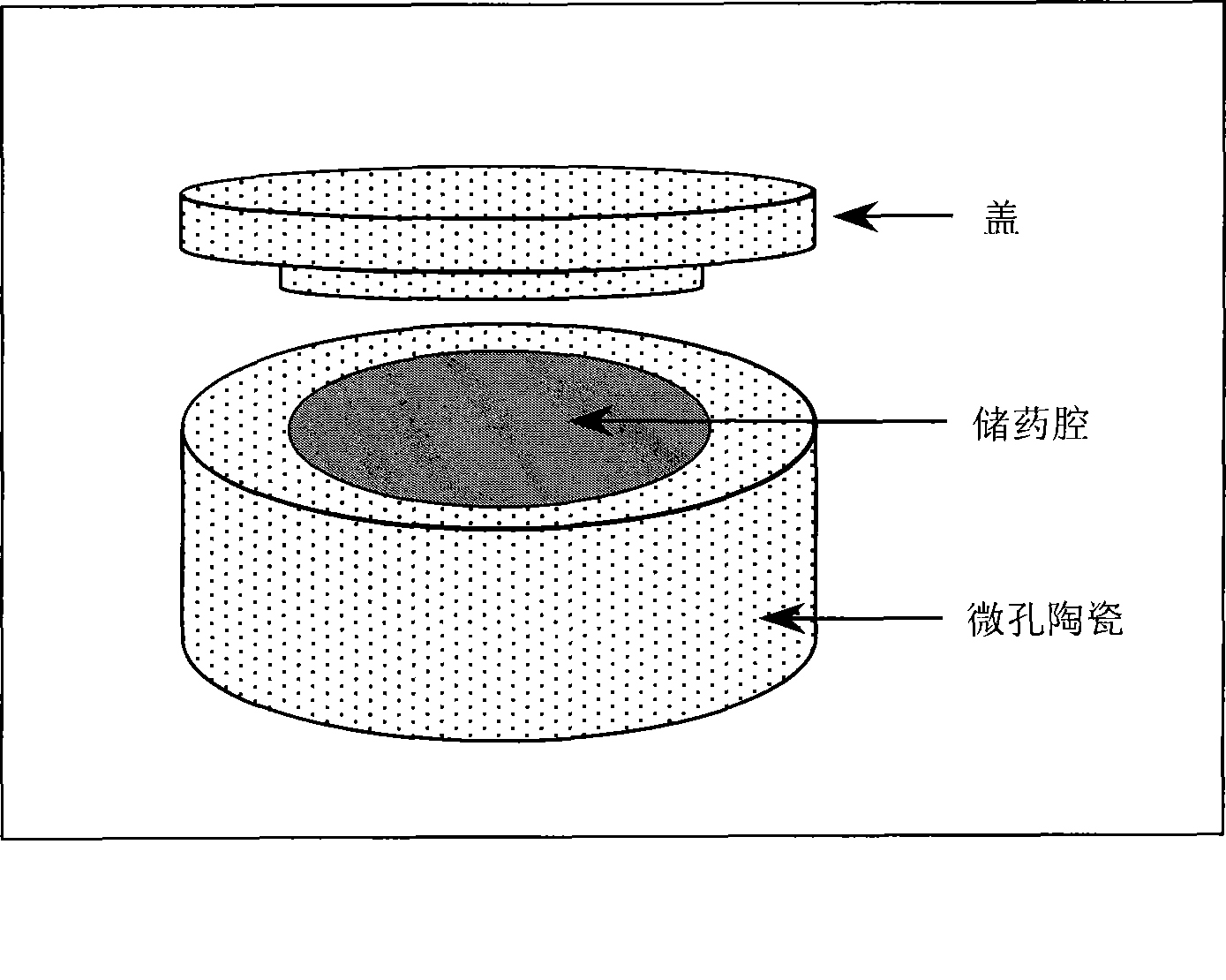

[0032] Adopt the tricalcium phosphate of powder grain 1-2 micron as ceramic raw material, make the cylindrical microporous ceramic box of diameter 30 millimeters and height 20 millimeters, wall and lid thickness are 5 millimeters ( image 3 ). The micropore diameter is 1-2 microns, and the microporosity is 5%.

[0033] Specific steps are as follows:

[0034] 1) Make corresponding molds according to the shape and size of the product;

[0035] 2) 65% ceramic powder + 30% pure water + 5% dispersant and binder were stirred for 3 hours to prepare a slurry;

[0036] 3) The slurry is poured into the mold, dried for 10 hours to form, demolded and trimmed to obtain a ceramic green body;

[0037] 4) Move the green body into the debinding furnace and heat up to 370°C to eliminate organic matter;

[0038] 5) Move it into a high-temperature sintering furnace, gradually heat up to 1000°C, and sinter for 3 hours to form a microporous ceramic product.

Embodiment 2

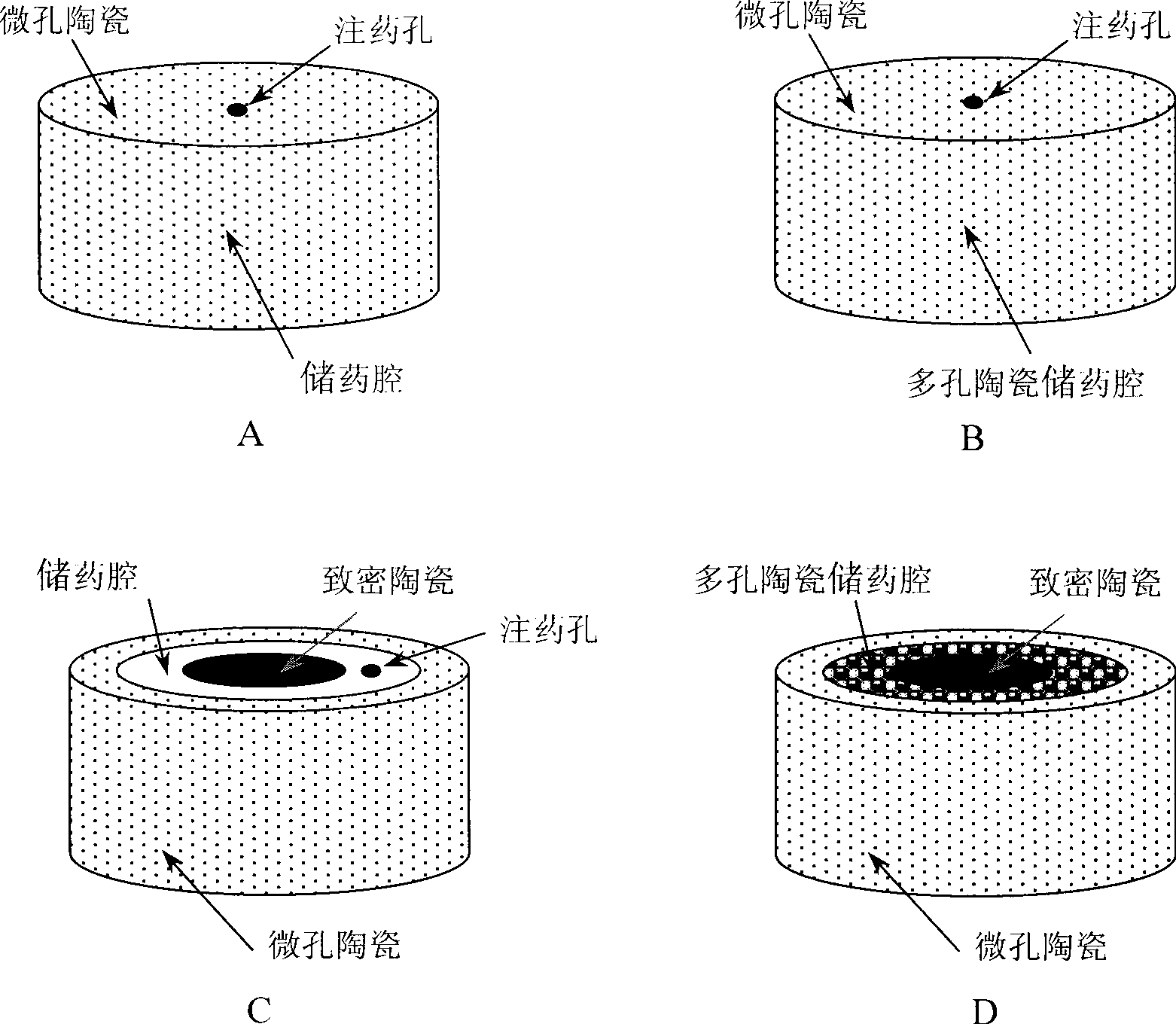

[0040] Adopt tricalcium phosphate (85%) of powder 1-2 micron and charcoal of 2-4 micron as microporous agent (15%), make the cylindrical microporous ceramic box of diameter 30 millimeters and height 20 millimeters, wall thickness 5 mm, the drug storage cavity is cylindrical with a diameter of 20 mm and a height of 10 mm, and a drug injection hole with a diameter of 0.5 to 1.5 mm communicated with the drug storage cavity on the top ( figure 2 -A). The micropore diameter is 1-3 microns, and the microporosity is 15%.

[0041] Specific steps are as follows:

[0042] 1) Make corresponding molds according to the shape and size of the product;

[0043] 2) 85% ceramic powder + 15% microporous agent was stirred for 3 hours to make a mixture;

[0044] 3) Pour the mixture into the mold, continue to press at 100MPa for 30 minutes, and demould to form a ceramic green body;

[0045] 4) Move the green body into the debinding furnace and heat up to 500°C to eliminate organic matter;

[...

Embodiment 3

[0048] Tricalcium phosphate with a powder size of 2-4 microns is used as a ceramic raw material, and PMMA spherical particles with a size of 300-500 microns are used as a pore-forming agent. Make a cylindrical microporous ceramic box with a diameter of 30 mm and a height of 20 mm. The wall thickness is 5 mm. Injection hole ( figure 2 -B). The microporous ceramic part has a pore size of 1-3 microns and a porosity of 15%. The porous ceramic part has a pore size of 350-450 microns and a porosity of 65%.

[0049] Specific steps are as follows:

[0050] 1) Make corresponding molds according to the shape and size of the product;

[0051] 2) Place PMMA spherical particles in the mold cavity, add acetone for 10 minutes, and rinse with pure water to obtain a cylindrical porous framework;

[0052] 3) 65% ceramic powder + 30% pure water + 5% dispersant and binder, mixed for 3 hours to prepare a slurry;

[0053] 4) placing the porous framework in the cavity of the mold and pouring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com