Fresh fruit pure jelly and method for producing the same

A production method and fresh fruit technology, which are applied in food preparation, application, food science and other directions, can solve the problems of fruit freshness, taste, flavor and color, loss of nutrients, and high production cost, reduce tinplate corrosion pollution, eliminate Oxidation and browning, resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, the fresh fruit jelly is made of the following raw materials in parts by weight: water 63, cantaloupe fresh pulp 18, fructose syrup 5, white granulated sugar 15, citric acid 0.2, sodium citrate 0.15, cyclamate 0.01, cantaloupe essence 0.08, Sodium tripolyphosphate 0.03, potassium sorbate 0.03, sunset yellow 0.001, carrageenan 0.2, konjac gum 0.35, xanthan gum 0.02, rose bean gum 0.03.

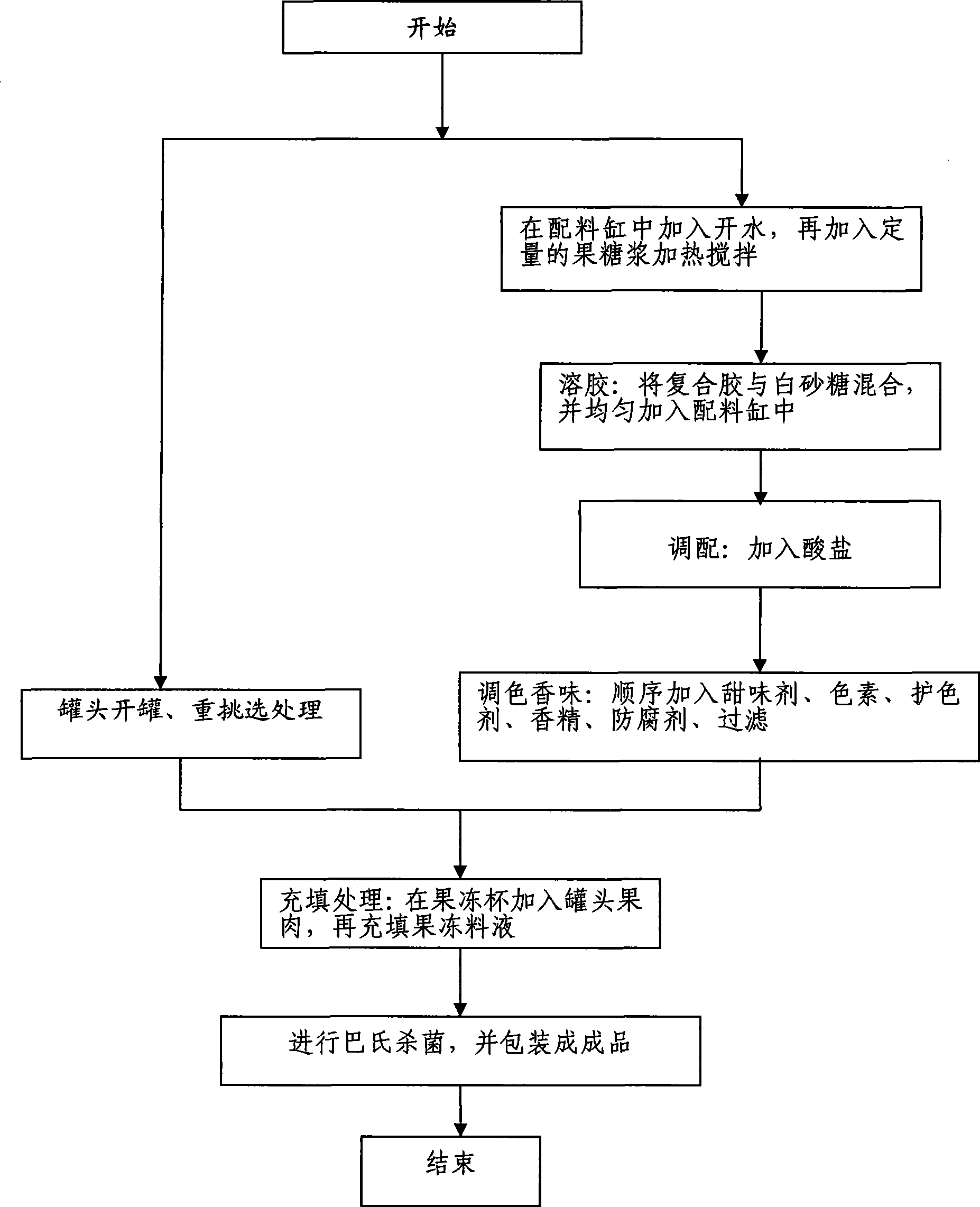

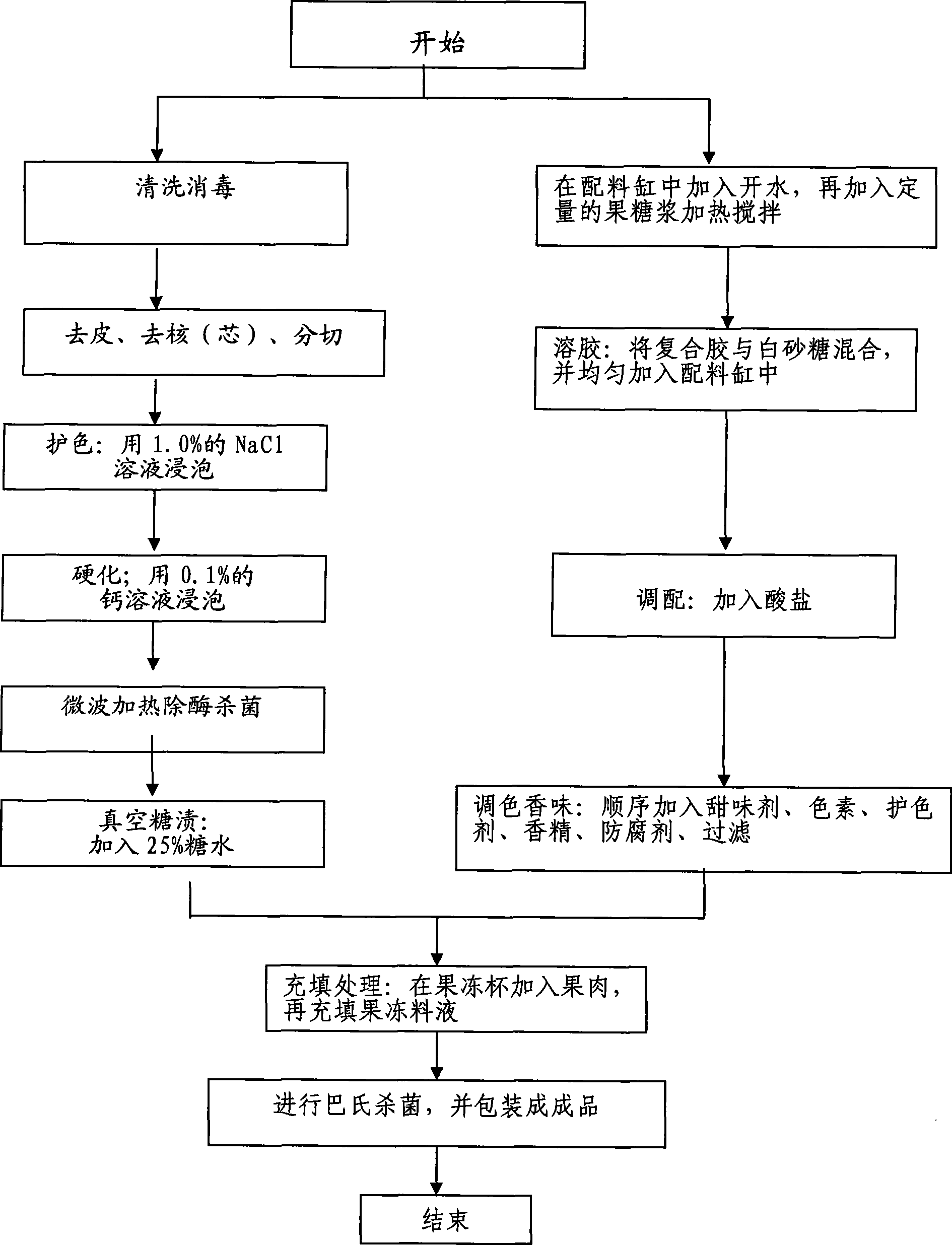

[0039] Such as figure 2 Shown is the flow chart of fresh fruit jelly preparation.

[0040] Preparation method of fresh fruit jelly:

[0041] (1), fresh fruit treatment: wash the fresh fruit - Hami melon with water, then disinfect with 10ppm chlorine dioxide solution, peel the sterilized fresh fruit, remove the core or core, cut it, then soak it in 1.5% NaCl solution for 10min, Soak in 0.1% calcium lactate for 5 minutes, heat in microwave for 5 minutes to 75°C to remove enzymes and sterilize, then add 25.0% sugar water, wherein the amount of sugar water accounts for 40% o...

Embodiment 2

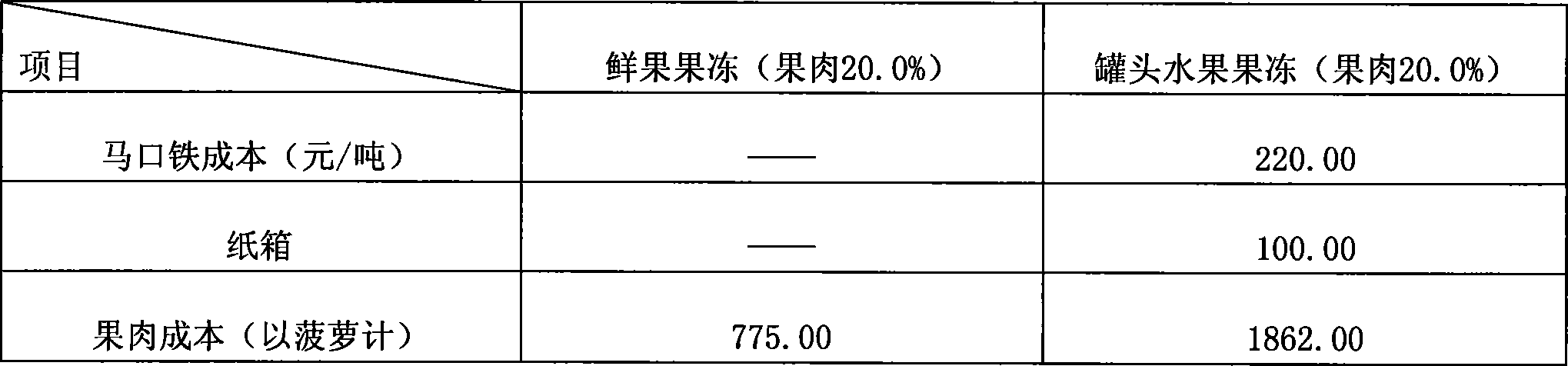

[0045] Embodiment 2, fresh fruit jelly is made from the following raw materials in parts by weight: water 55, pineapple fresh pulp 17, white granulated sugar 10, fructose syrup 8.5, citric acid 0.3, sodium citrate 0.12, pineapple flavor 0.09, ethylenediaminetetra Disodium acetate 0.05, potassium sorbate 0.04, sunset yellow 0.002, carrageenan 0.3, konjac gum 0.25, xanthan gum 0.01, rose bean gum 0.05. Preparation method of fresh fruit jelly:

[0046] (1) Fresh fruit treatment: Wash the fresh fruit—pineapple with water, then disinfect it with 10ppm chlorine dioxide solution, peel the sterilized fresh fruit, remove the core or core, cut it, and then soak it in 1% NaCl solution for 30 minutes, Soak in 0.1% calcium chloride for 10 minutes, heat in microwave for 4 minutes to 70°C to remove enzymes and sterilize, then add 25.0% sugar water, where the amount of sugar water accounts for 50% of the pulp, and vacuum at -0.05Mpa for 5 hours ;

[0047] (2) Other raw materials except fres...

Embodiment 3

[0050]Example 3, the fresh fruit jelly is made from the following raw materials in parts by weight: 70 parts by weight of water, 30 parts of fresh apple pulp, 4 parts of white sugar, 0.1 of citric acid, 0.14 of sodium citrate, 0.1 of apple essence, 0.04 of sodium tripolyphosphate, and potassium sorbate 0.05, tartrazine 0.0015, carrageenan 0.35, konjac gum 0.2, xanthan gum 0.05, rose bean gum 0.01.

[0051] Preparation method of fresh fruit jelly:

[0052] (1), fresh fruit treatment: wash the fresh fruit - Hami melon with water, then sterilize with 10ppm chlorine dioxide solution, peel the sterilized fresh fruit, remove the core or core, cut it, then soak it in 1.2% NaCl solution for 5min, Soak in 0.1% calcium lactate for 8 minutes, heat in microwave for 3 minutes to 65°C to remove enzymes and sterilize, then add 25.0% sugar water, where the amount of sugar water accounts for 45% of the pulp, and vacuum for 4 hours at -0.06Mpa;

[0053] (2) Other raw materials except fresh fru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com