Method for preparing stannic oxide nano wire

A tin dioxide and nanowire technology, applied in the direction of tin oxide, etc., can solve the problems of complex post-treatment process, small output limitation of tin dioxide, etc., achieving good crystallinity, easy industrialized continuous production, uniform structure and size controllable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

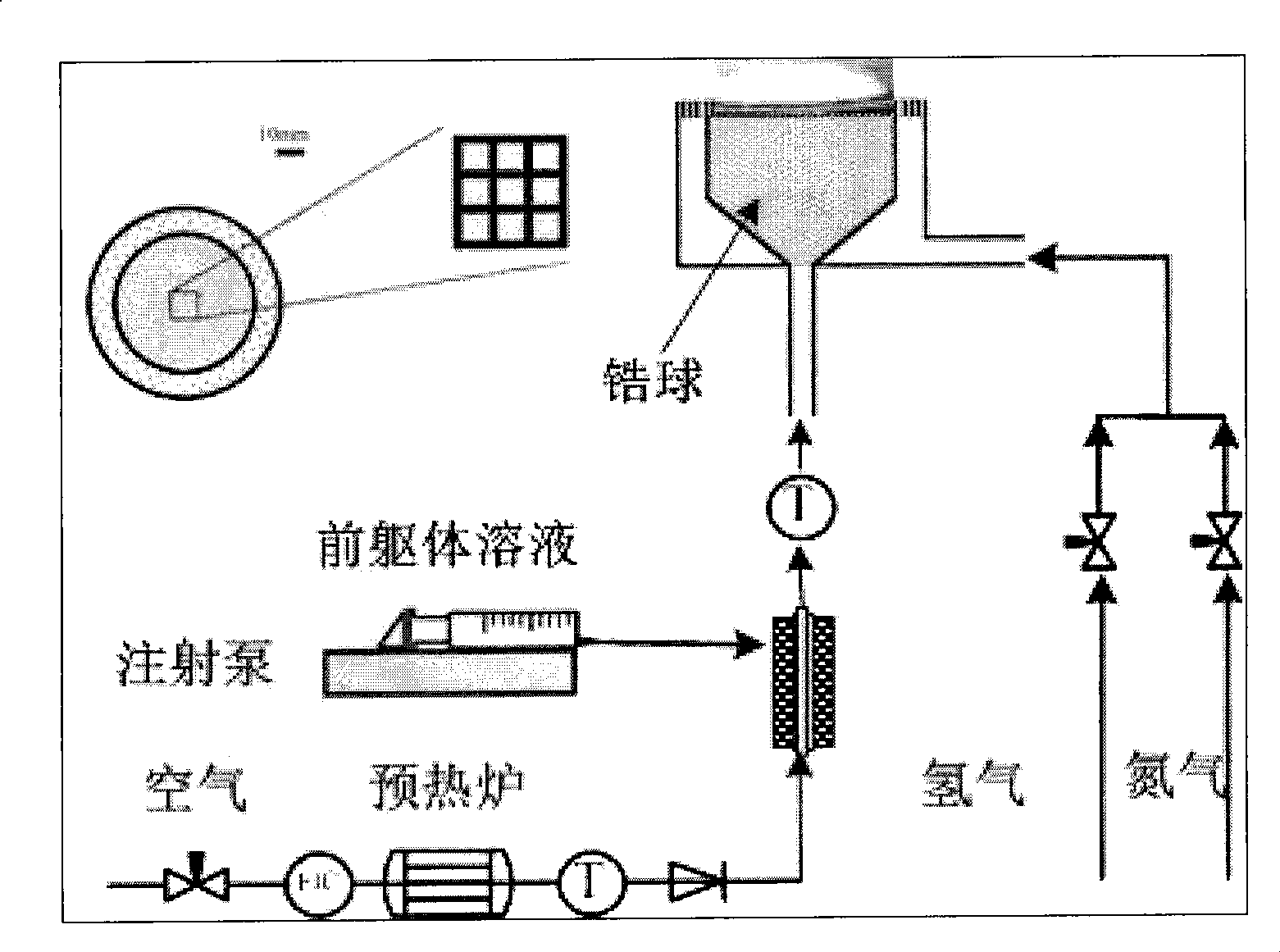

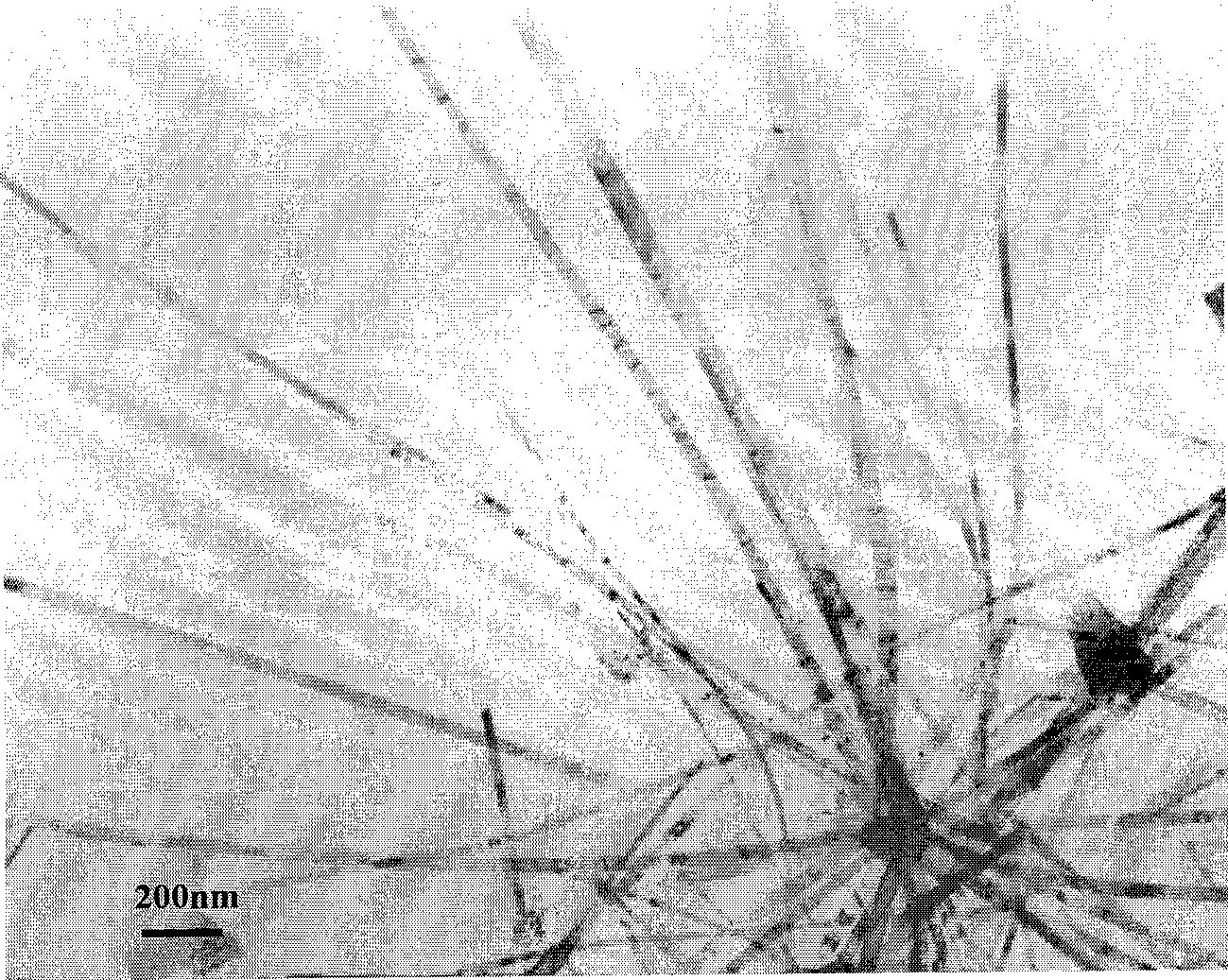

[0017] The flow chart of the continuous large-scale preparation method of tin dioxide nanowires is as follows figure 1 As shown, use a syringe to slowly drop 10ml tin tetrachloride into 100ml ethanol to form a precursor solution. 3 / h Air is mixed, and the mixed steam forms a flat flame at the burner mouth. The porous cordierite substrate (which can also be a substrate of stainless steel or an inert ceramic material) is placed in parallel on the burner plate, deposited for 100 min, and the reaction temperature is 800°C. In order to prevent condensation during the transmission of mixed steam, the evaporator and transmission pipes are all kept at a constant temperature of 200°C. The obtained sample has a length of about 4 μm, a diameter of 40 nm, an aspect ratio of 100, and a relatively uniform size. The electron microscope photos are as follows: figure 2 shown.

Embodiment 2

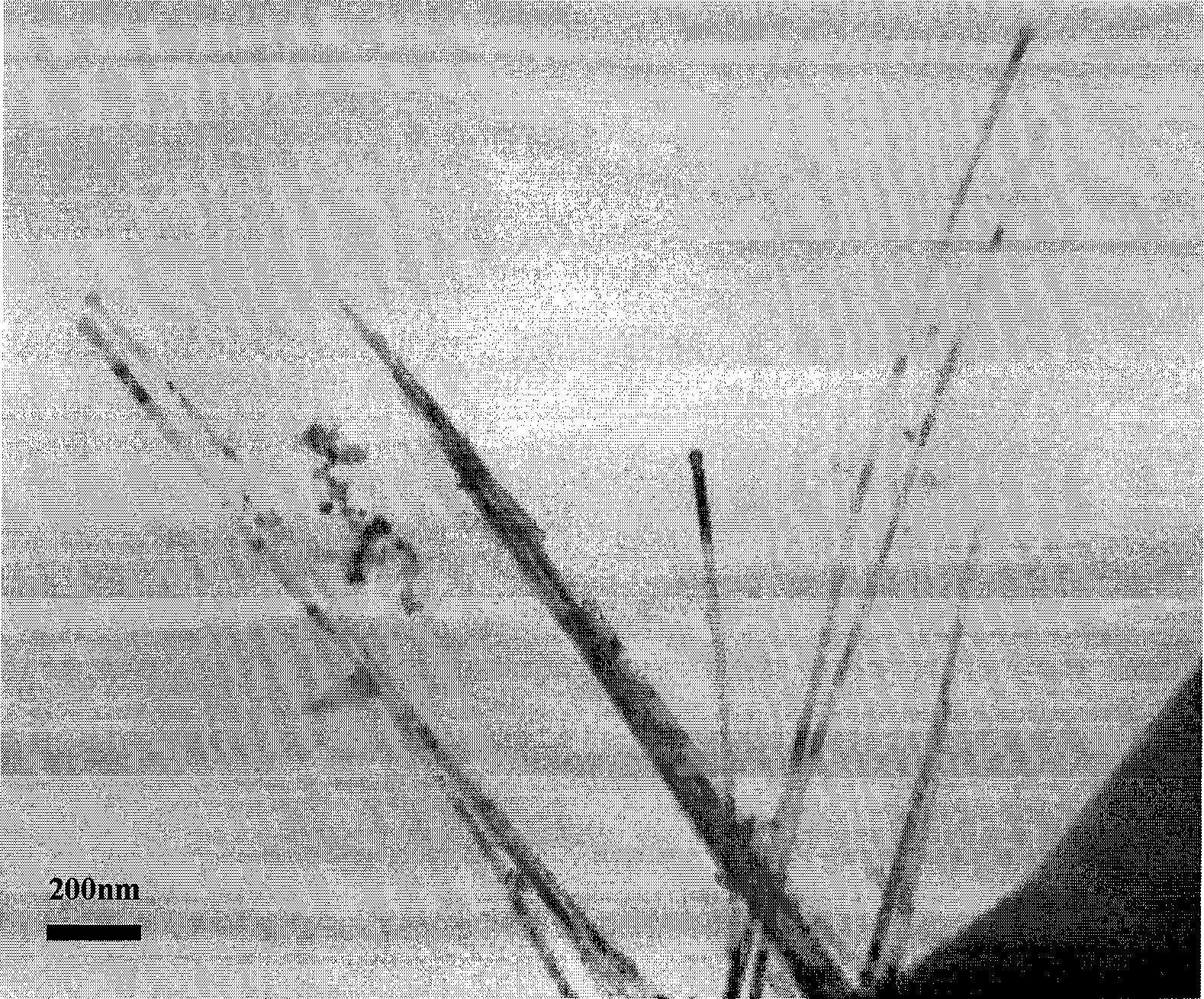

[0019] The flow chart of the continuous large-scale preparation method of tin dioxide nanowires is as follows figure 1 As shown, use a syringe to slowly drop 7ml of tin tetrachloride into 100ml of ethanol to form a precursor solution. 3 / h Air is mixed, and the mixed steam forms a flat flame at the burner mouth. The porous cordierite substrate (which can also be a substrate of stainless steel or inert ceramic material) is placed in parallel on the burner plate and deposited for 10 minutes. As the deposition time prolongs, the length of the nanowires will become longer. The reaction temperature is 700°C. In order to prevent condensation during the transmission of mixed steam, the evaporator and transmission pipes are all kept at a constant temperature of 200°C. The length of the obtained sample is 1.5 μm, the diameter is about 20 nm, the aspect ratio reaches 75, and the size is relatively uniform. The electron microscope photos are as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com