Nickel-cobalt composite hydroxide ultralong nanobelt, nickel-cobalt composite oxide ultralong nanobelt and preparation method thereof

A technology of composite hydroxides and composite oxides, applied in nickel compounds, chemical instruments and methods, nanotechnology, etc., can solve the problems of cumbersome preparation of ultra-long nanoribbons, high energy consumption in the preparation process, and uneven products. Achieve good radial charge transport capability, controllable nanometer bandwidth, and solve the effect of cumbersome preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Prepare 60 mL of an aqueous solution with a molar ratio of nickel sulfate and cobalt nitrate of 10:6, in which the concentration of nickel ions is 0.05 mol / L;

[0038] (2) Prepare sodium hydroxide with distilled water into 0.1 mol / L aqueous solution;

[0039] (3) Under stirring, take 3 mL of the sodium hydroxide aqueous solution prepared in step (2), add dropwise the nickel cobalt salt solution prepared in (1), and stir for 30 minutes to obtain mixed solution I;

[0040] (4) Pour the above mixed liquid I into a closed reactor, heat it to 80 degrees Celsius, and then react at this temperature for 120 hours at a constant temperature;

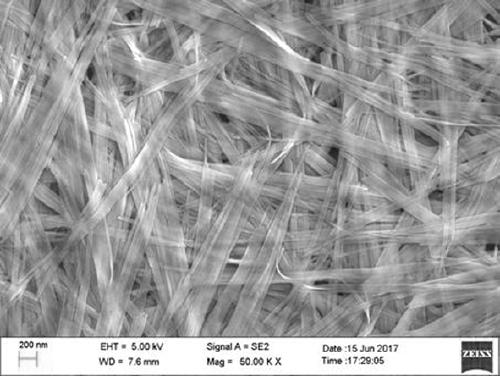

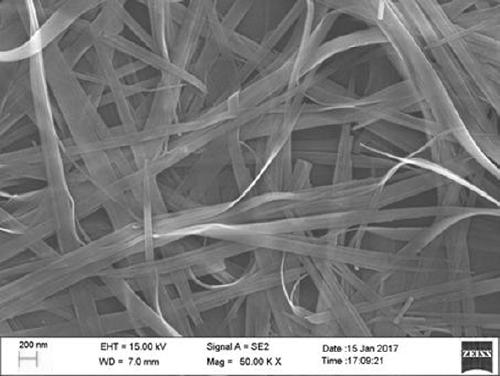

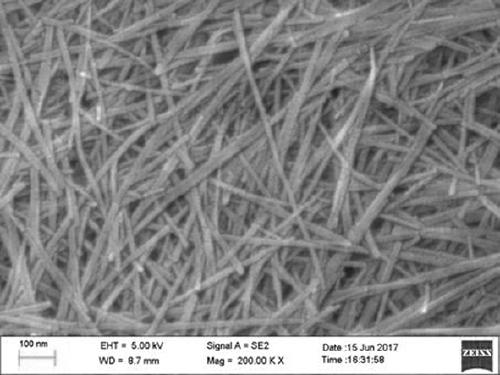

[0041] (5) After the reaction is over, the reaction solution is cooled, the reaction product is filtered, centrifuged or dialysis washed with deionized water to remove the soluble salt ions in the product, and the solid product obtained is the nickel-cobalt composite hydroxide super long Nanobelt

[0042] (6) Disperse the obtained solid product ...

Embodiment 2

[0048] (1) Prepare 60 mL of an aqueous solution with a molar ratio of nickel sulfate and cobalt sulfate of 10:4, in which the concentration of nickel ions is 0.25 mol / L;

[0049] (2) Under stirring, add 0.3 g of sodium hydroxide to the nickel cobalt salt solution prepared in (1), and stir for 10 minutes to obtain a mixed solution I;

[0050] (3) Pour the above mixed liquid I into a closed reactor, heat it to 100 degrees Celsius, and then react at this temperature for 48 hours at a constant temperature;

[0051] (4) Treat the reaction solution obtained in step (3) with the same treatment method as in steps (5), (6) and (7) in Example 1, to obtain the nickel-cobalt composite hydroxide nanobelt and nickel-cobalt composite Oxide nanobelt.

[0052] Product performance:

[0053] (1) The ratio of nickel and cobalt in the nickel-cobalt composite hydroxide nanobelt product prepared in this embodiment is 10:3.5, the length is 40-50 µm, the width is 200-300 nm, and the thickness is between 20-30 ...

Embodiment 3

[0062] (1) Prepare 60 mL of an aqueous solution with a molar ratio of nickel sulfate and cobalt chloride of 10:3, in which the concentration of nickel ions is 0.25 mol / L;

[0063] (2) While stirring, add 12 mL of 1 mol / L lithium hydroxide aqueous solution to the nickel cobalt salt solution configured in (1), and stir for 20 minutes to obtain mixed solution I;

[0064] (3) Pour the above mixed liquid I into a closed reactor, heat it to 120 degrees Celsius, and then react at this temperature for 24 hours at a constant temperature;

[0065] (4) Treat the reaction solution obtained in step (3) with the same treatment method as in steps (5), (6) and (7) in Example 1, to obtain the nickel-cobalt composite hydroxide nanobelt and nickel-cobalt composite Oxide nanobelt.

[0066] Product performance:

[0067] (1) The nickel-cobalt composite hydroxide nanobelt product prepared in this embodiment has a ratio of nickel and cobalt elements of 10:2.8, a length of 30-60 µm, a width of 200-300 nm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com