Method for preparing oxygen and nitrogen by air separation

An air separation and oxygen technology, applied in separation methods, chemical instruments and methods, oxygen preparation, etc., can solve the problems of difficulty in oxygen purity higher than 95%, low oxygen production efficiency, poor adsorption selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Oxygen separation performance of oxygen-permeable ceramic membrane

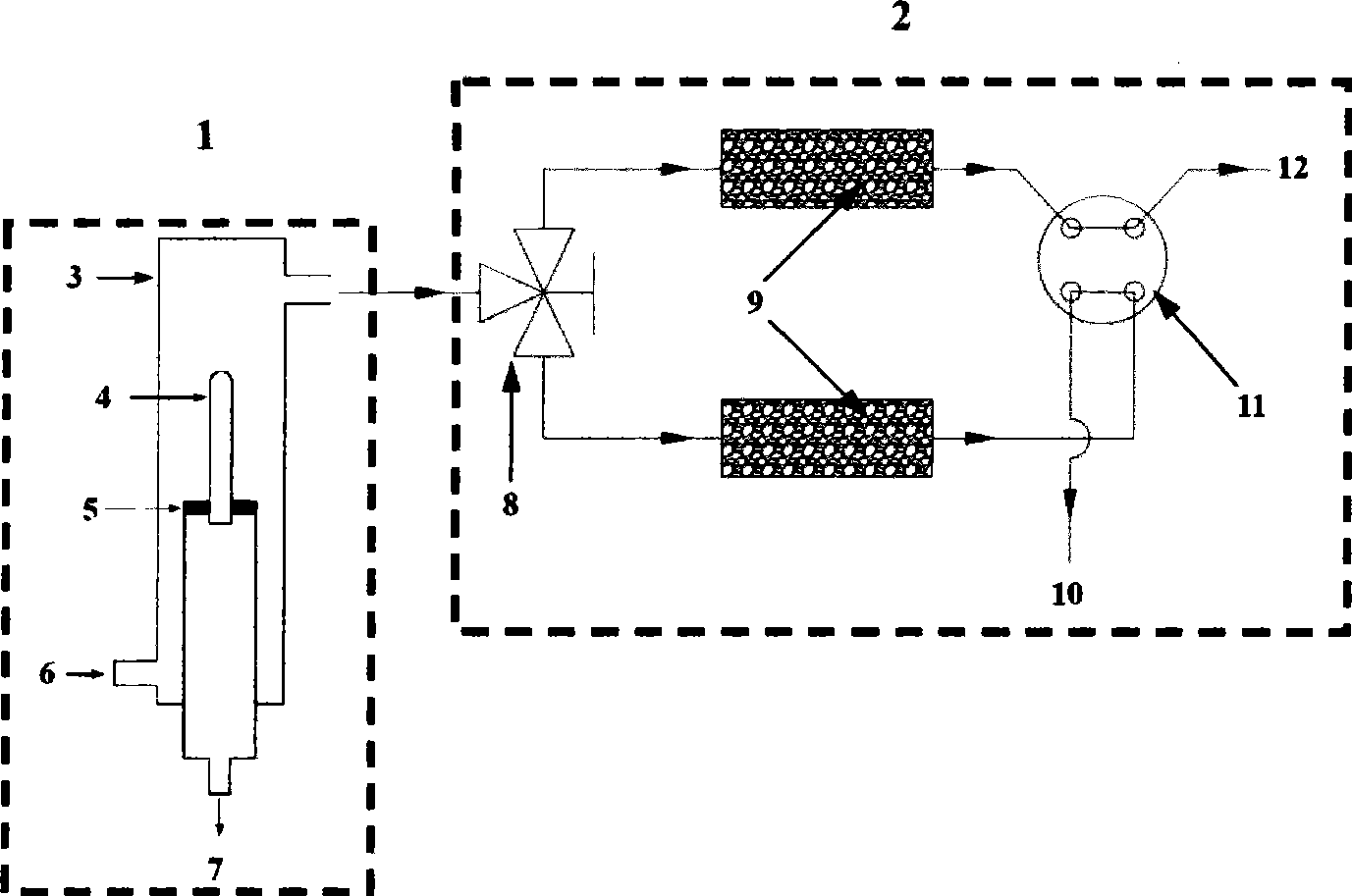

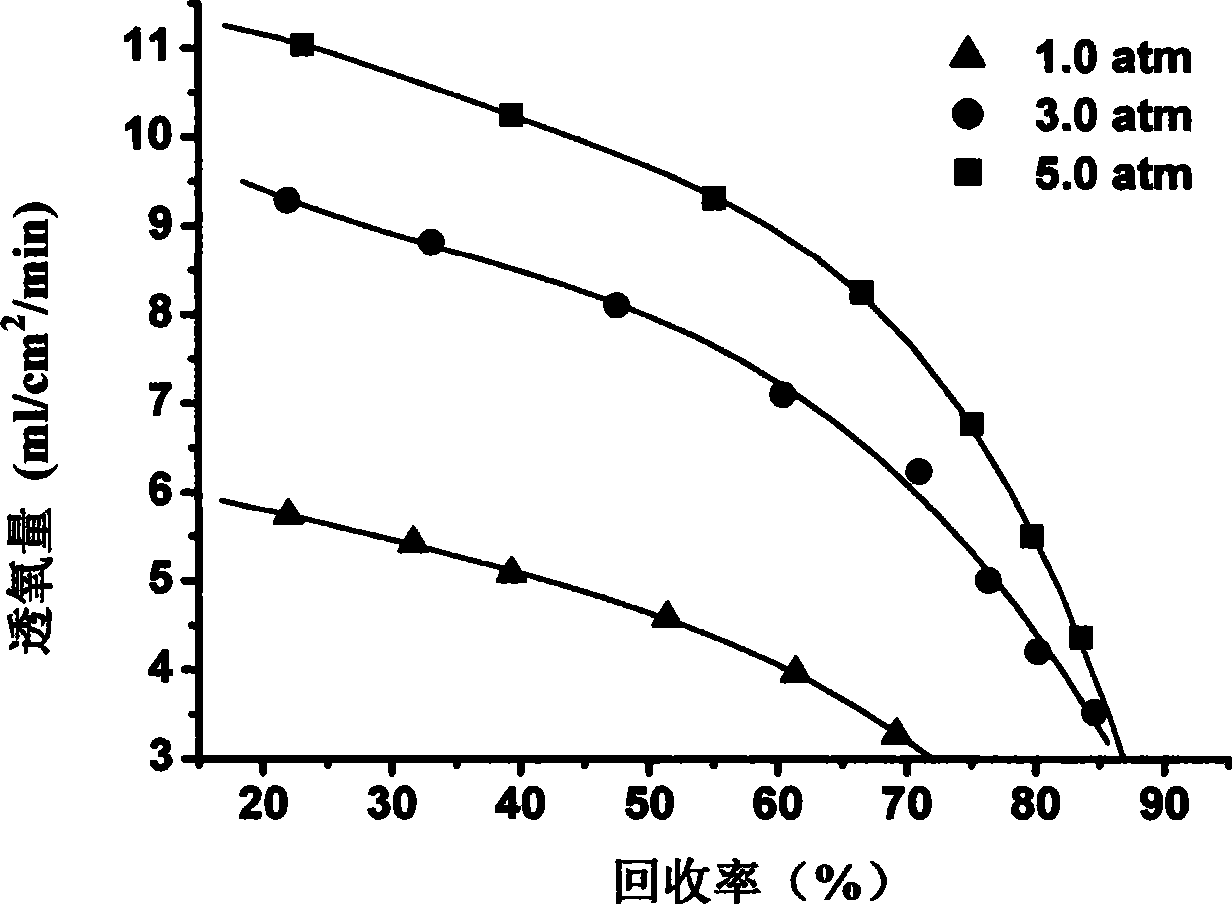

[0025] The prepared oxygen-permeable ceramic membrane tube is composed of figure 1The oxygen permeable ceramic membrane permeator shown in . The outer casing of the permeator is a stainless steel tube, and the length and diameter of the oxygen-permeable ceramic membrane tube are determined according to the size of the specific separator. The outer diameter of the membrane tube used in this embodiment is 2.5 mm, the inner diameter is 1.5 mm, and the length is 6 cm; one end of the membrane tube is sealed, and the other end is connected with a quartz tube, and the quartz inner tube is connected with an oil-free dry pump. After the membrane tube is sealed at high temperature, air is introduced. The air flow rate is 50-1000ml / min. At 925°C, the relationship between the oxygen permeability of the oxygen-permeable ceramic membrane and the oxygen recovery rate was studied by changing the air flow ...

Embodiment 2

[0026] Example 2 Oxygen adsorption and desorption cycle performance of complex metal oxides

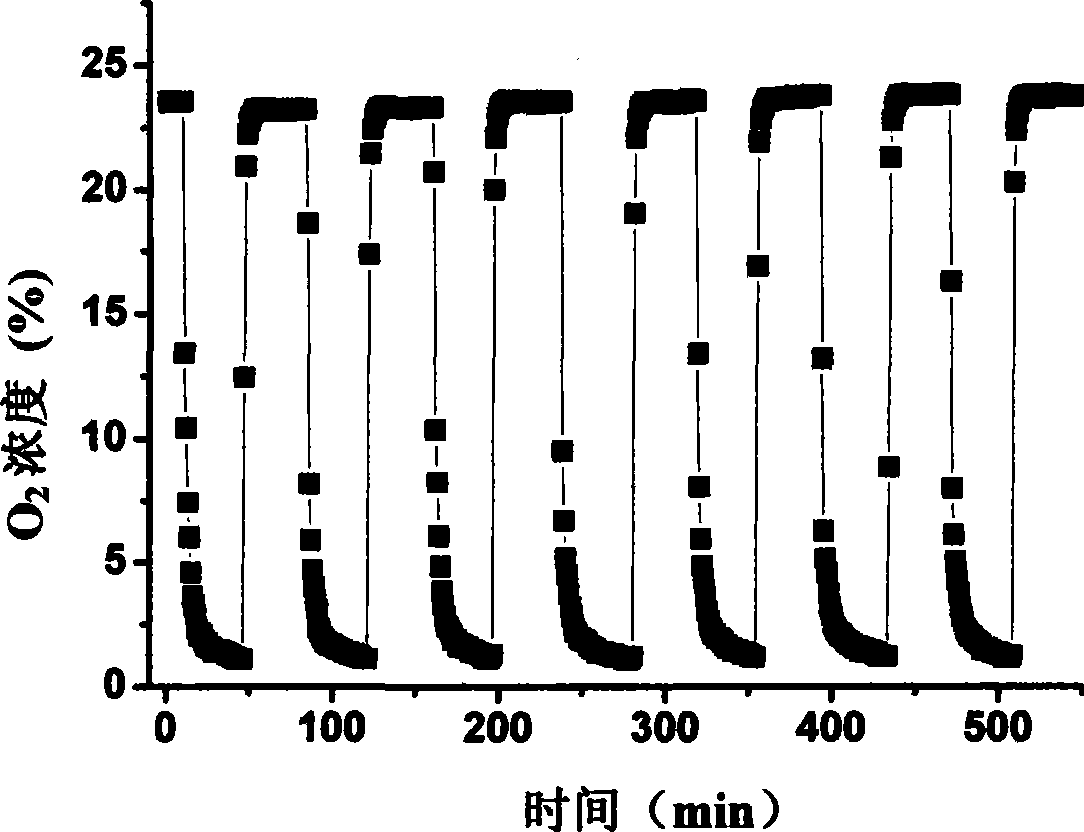

[0027] The prepared complex metal oxide powder is ground and granulated. The adsorbent can be amorphous, spherical, cylindrical, honeycomb, etc. The particle size depends on the size of the adsorption separator. In this embodiment, an adsorption separator is used to realize the regeneration of the adsorbent by means of vacuum pumping, so as to study the adsorption-desorption cycle performance of the adsorbent. The particle size of the adsorbent used is 20-30 mesh, and the adsorbent consumption of the pressure swing adsorption separator is 23 grams. image 3 The adsorption and regeneration cycles of complex metal oxide adsorbents are given. from image 3 It can be seen that the adsorbent has a good cycle ability. The adsorption capacity of such adsorbents is generally small (<10ml / g). Using this kind of adsorbent alone to separate air has limited production capacity and is not su...

Embodiment 3

[0028] Example 3 Oxygen adsorption capacity of complex metal oxides

[0029] The particle size of the adsorbent used in this example is 20-30 mesh, and the adsorbent is regenerated by purging with inert gas (He) to study the oxygen adsorption capacity of complex metal oxides. The amount of adsorbent used is 7 grams, and the operating temperature is 470°C. Under these conditions, the adsorption capacity of the adsorbent is 4ml / g. Increase the adsorption pressure to 2MPa, and the adsorption capacity of the adsorbent increases to about 6ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com