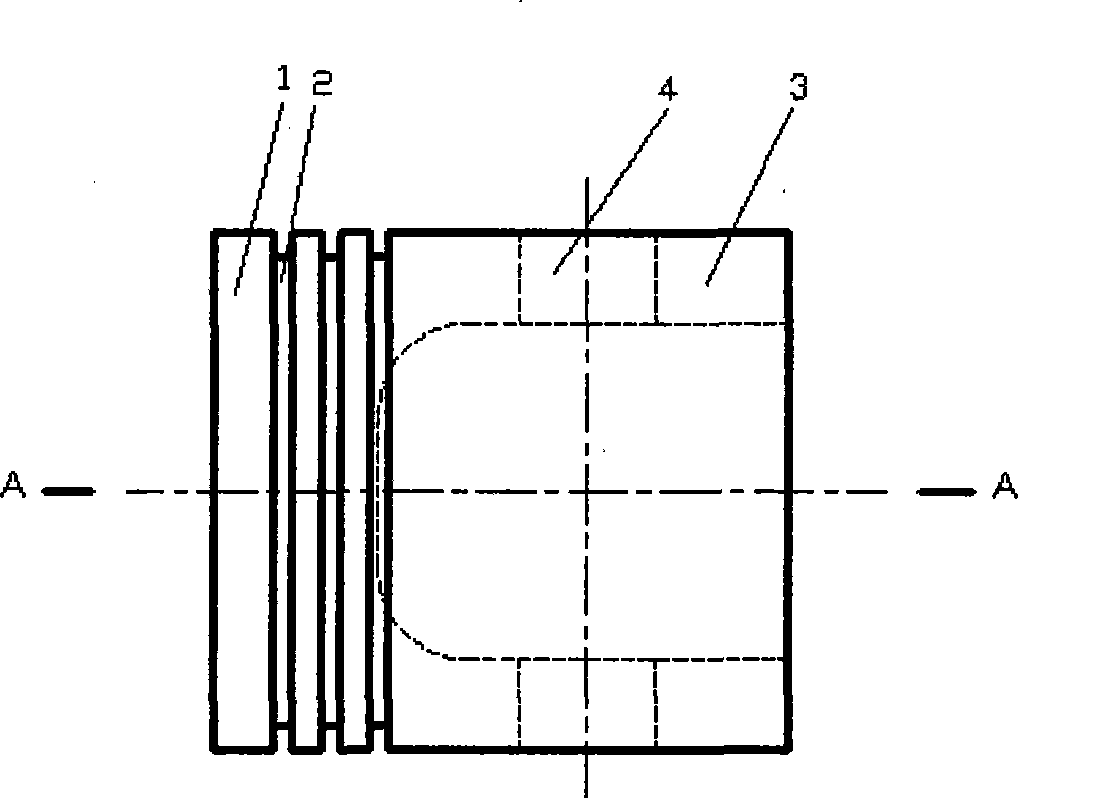

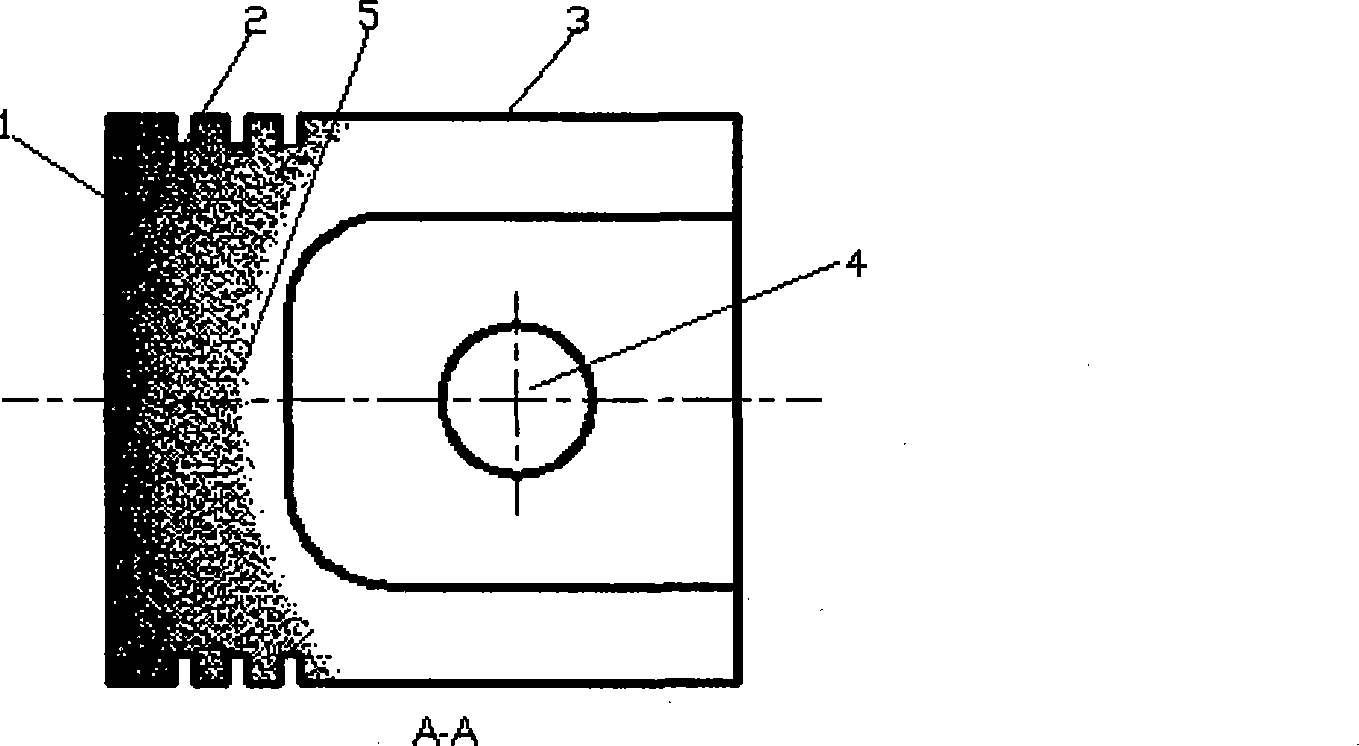

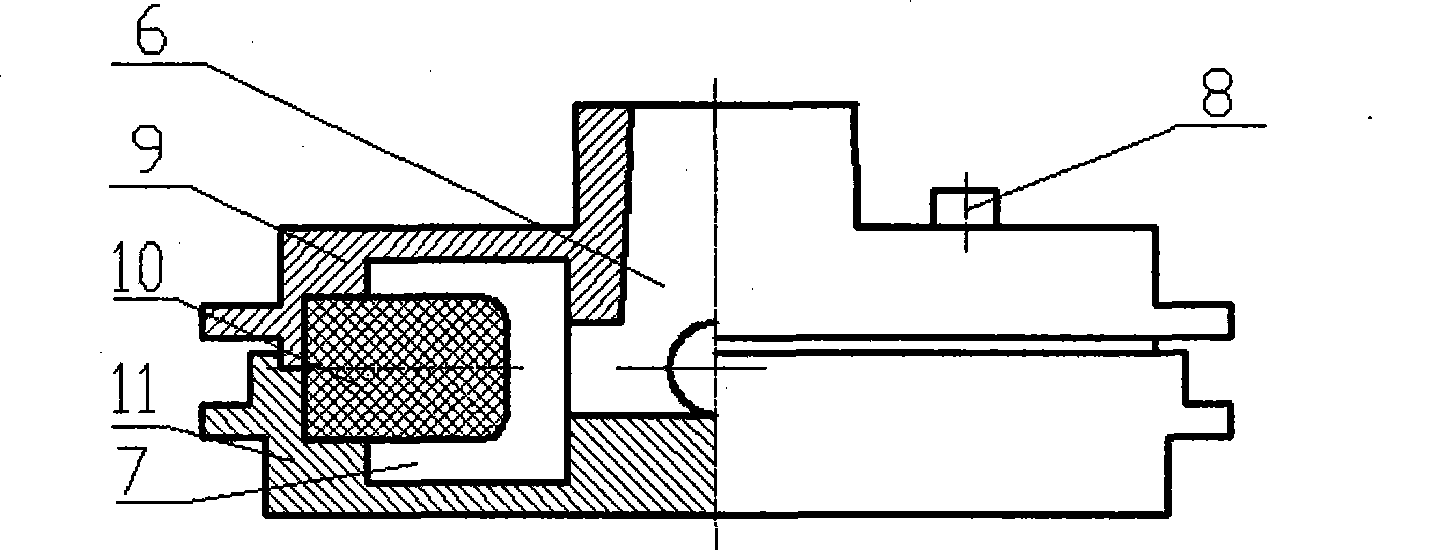

Piston made of Al/Si-Mg*Si composite material and preparation method thereof

A technology of composite materials and pistons, which is applied in the direction of pistons, cylindrical pistons, plungers, etc., can solve the problems of heat treatment to improve cutting performance, complex material making process, and difficult machining, so as to achieve firm interface bonding, simple process, and high quality. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The alloy composition is Al-16Si-2Mg, the mass percentage of Ni, Cu, Ti, Mn, Re and other trace alloy elements is less than 5%, the hardness of the top of the piston is as high as HB120, the room temperature strength is higher than 250MPa, the high temperature strength is higher than 60Mpa, and the thermal expansion coefficient Below 15 x 10 -6 / °C.

Embodiment 2

[0028] The alloy composition is Al-16Si-5Mg, and the mass percentage of trace alloy elements such as Ni, Cu, Ti, Mn and Re is less than 5%. The hardness of the top of the piston is as high as HB120, the strength at room temperature is higher than 250MPa, the strength at high temperature is higher than 60MPa, and the coefficient of thermal expansion is lower than 15 x 10 -6 / °C.

Embodiment 3

[0030] The alloy composition is Al-16Si-8Mg, and the mass percentage of trace alloy elements such as Ni, Cu, Ti, Mn and Re is less than 5%. The hardness of the top of the piston is as high as HB120, the strength at room temperature is higher than 250MPa, the strength at high temperature is higher than 60MPa, and the coefficient of thermal expansion is lower than 15 x 10 -6 / °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com