Multi-functional rubber additive and method for preparing same

A rubber additive and multifunctional technology, which is applied in the synthesis of rubber additives and the field of filler-reinforced rubber, can solve the problems of difficulty in meeting the requirements of the rubber industry and the single function of rubber additives, so as to improve dynamic mechanical properties and other properties, Improved mechanical properties and dynamic mechanical properties, long scorch time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 0.1mol (16.7g) of 2-mercaptobenzothiazole and 250g of toluene into a three-necked round-bottomed flask, add 0.1mol (5.4g) of sodium methoxide, stir well, and heat the mixture to 120°C. And from one side of the three-necked flask at a distance of 0.1m 3 Nitrogen gas was introduced at a speed of 1 / h, and then 0.1mol (28.86g) γ-chloropropyltriethoxysilane was added to the above solution, and then reacted at 120°C for 18 hours under the protection of nitrogen gas, and the obtained product would settle The product was filtered, and the low-boiling fraction was distilled off under reduced pressure to obtain a yellow viscous liquid product with a yield of 93.5%.

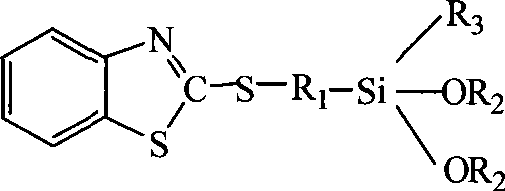

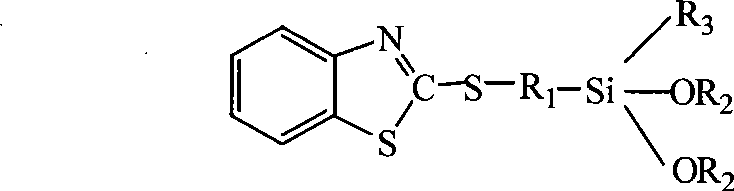

[0021] The obtained product is 3-benzothiazolethio-1-propyl-triethoxysilane, named as Silane-M. Infrared spectroscopy (FTIR), gas chromatography-mass spectroscopy (GC-MS), elemental analysis and nuclear magnetic resonance (NMR) results showed that the synthesized product was the target product Silane-M.

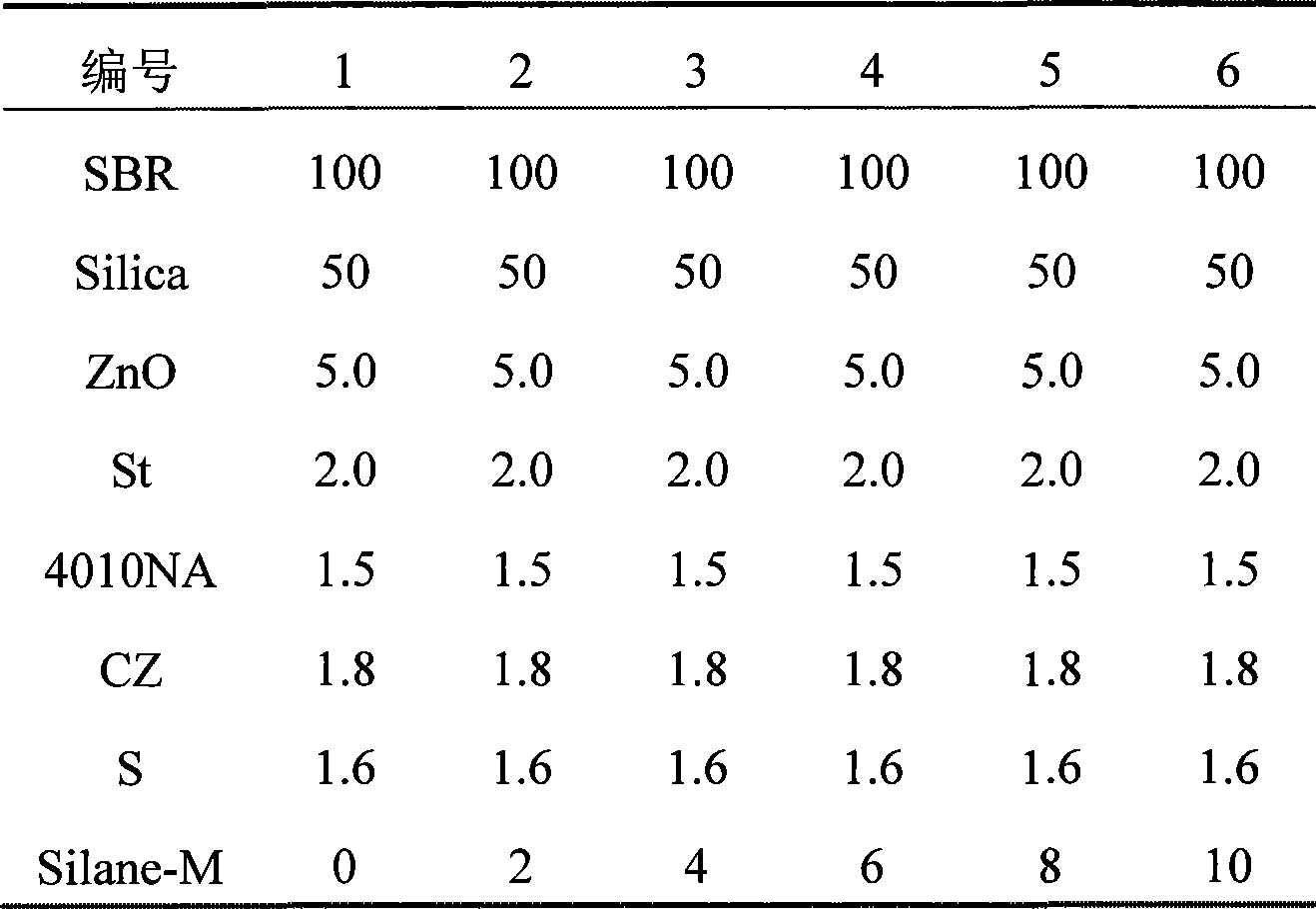

[00...

Embodiment 2

[0033] Weigh 1mol (167g) of 2-mercaptobenzothiazole and 1.2kg of ethanol, place in a stainless steel container, add 1.5mol (87g) of sodium ethoxide, stir well, then add 1.5mol (336.8g) of γ-chloropropane Diethyl ethyldiethoxysilane was added to the above solution, and then reacted at 60°C for 0.5 hours under the protection of nitrogen, the obtained product was filtered, and the low boiling point fraction was removed by distillation under reduced pressure to obtain a yellow viscous liquid product 3 -Benzothiazolethio-1-propyl-ethyldiethoxysilane, named Silane-H, yield 76.2%.

[0034] Infrared spectroscopy (FTIR), gas chromatography-mass spectroscopy (GC-MS), elemental analysis and nuclear magnetic resonance (NMR) results showed that the synthesized product was the target product Silane-H.

[0035] The basic formulation of the silica-filled styrene-butadiene rubber unvulcanized rubber prepared with the product Silane-H is shown in Table 5 (unit: parts by weight), and the Mooney ...

Embodiment 3

[0046] Weigh 0.5mol (83.5g) of 2-mercaptobenzothiazole and 0.2kg of chloroform, place in a three-necked flask, add 0.75mol (30g) of sodium hydroxide, heat to 80°C, stir evenly, and blow in nitrogen , then add 0.5mol (85.25g) chloromethyltrimethoxysilane to the above solution, then react at 80°C for 6 hours under the protection of nitrogen, filter the precipitate, and distill under reduced pressure to remove the low boiling point fraction , and the yellow liquid product 3-benzothiazolethiomethyltrimethoxysilane was obtained with a yield of 83.7%.

[0047] Infrared spectroscopy (FTIR), gas chromatography-mass spectroscopy (GC-MS), elemental analysis and nuclear magnetic resonance (NMR) results showed that the synthesized product was the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com