Preparations of nano titanium dioxide particles and titania slurry

A technology of nano-titanium dioxide and titanium dioxide, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., to achieve the effect of maintaining stability, good stability and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

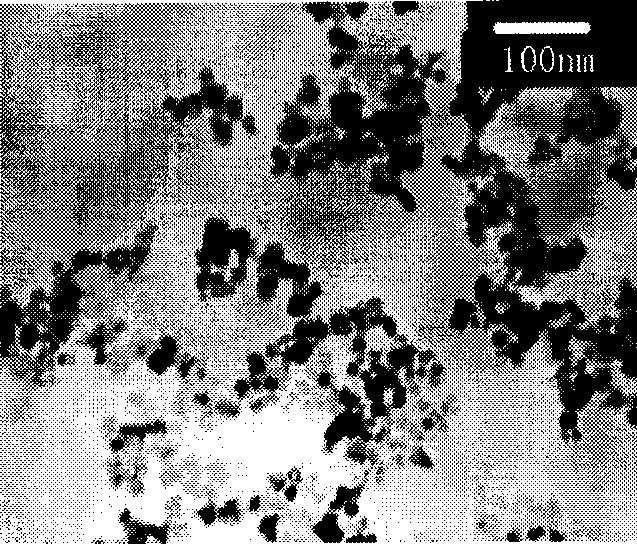

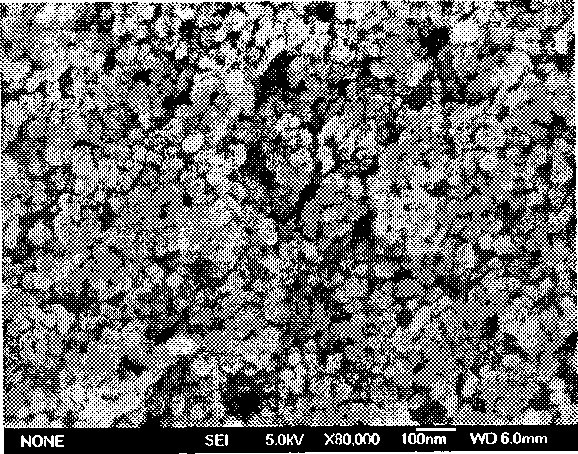

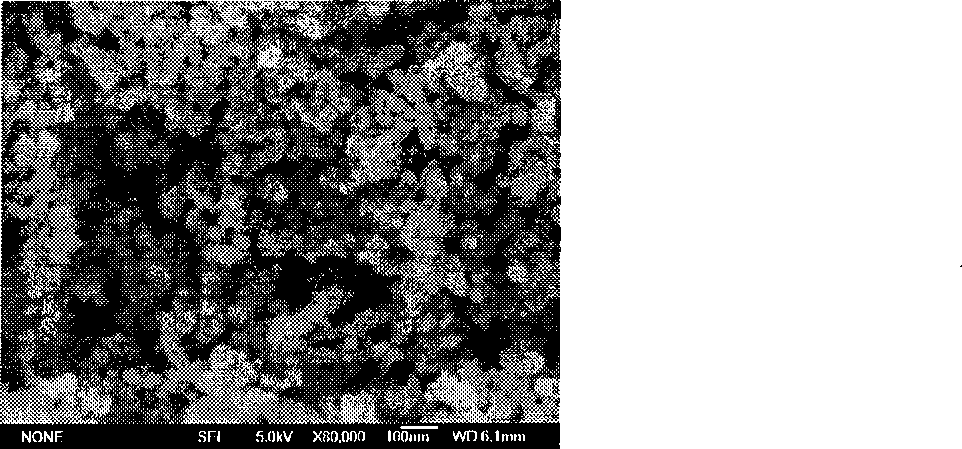

Image

Examples

Embodiment 1

[0025] (1) Precursor configuration

[0026] At room temperature, slowly add acetic acid (concentration 6mol / L) into tetrabutyl titanate, the volume ratio of acetic acid and tetrabutyl titanate is 1:5, stir while adding, and continue stirring for 15 minutes after the addition is complete. Then, the above mixture was added into 20 volumes of deionized water under strong stirring at 600 r / min, that is, the volume ratio of acetic acid: tetrabutyl titanate: water = 1:5:20. Continue to stir the mixture solution with white precipitate for 1 h, so that the hydrolysis reaction can be completely carried out. After 1h, add 1 / 2-1 volume of 10mol / L KOH solution to it, adjust the pH value of the mixture to 13, and at the same time raise the temperature of the mixture to 80°C during the stirring process and keep it warm for 1h to form a precursor mixture for hydrothermal reaction liquid.

[0027] (2) Hydrothermal synthesis of nano-titanium dioxide

[0028] Put the precursor mixture prepar...

Embodiment 2

[0035] (1) Precursor configuration

[0036] At room temperature, glacial acetic acid (density: 1.0492g / cm 3 ) Slowly add tetrabutyl titanate (density: 0.996g / cm 3 ), the volume ratio of acetic acid and tetrabutyl titanate is 1:8, stir while adding, and continue stirring for 30 minutes after the addition is complete. Then, the above mixture was added into 30 volumes of deionized water under strong stirring at 800 r / min, that is, the volume ratio of glacial acetic acid: tetrabutyl titanate: water = 1:8:30. Continue to stir the mixture solution with white precipitate for 1 h, so that the hydrolysis reaction can be completely carried out. After 1h, add 1 / 3-1 / 2 volume of 20mol / L NaOH solution to it, adjust the pH value of the mixture to 14, and at the same time raise the temperature of the mixture to 60°C during the stirring process, and keep it warm for 1.5h to form a hydrothermal reaction precursor mixture.

[0037] (2) Hydrothermal synthesis of nano-titanium dioxide

[0038...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com