Cerium-based composite oxides supported precious metal three-effect catalyst and preparation method thereof

A composite oxide, three-way catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Conversion performance, simple preparation process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

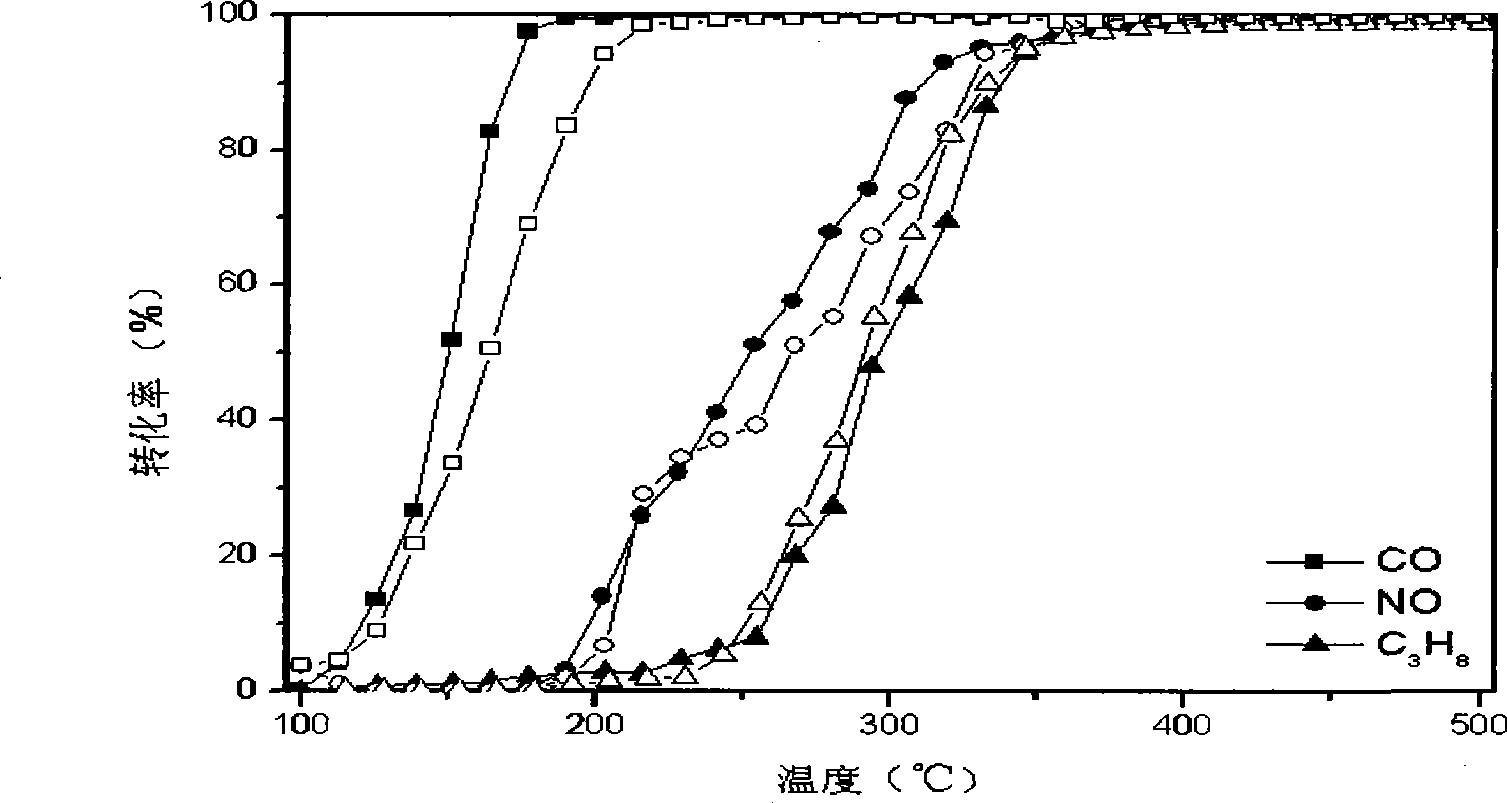

Embodiment 1

[0023] The ratio of CO:NO in the exhaust gas is 2.2%: 500ppm=44:1, and the air-fuel ratio λ=1.000.

[0024] Take 3.86g of cerous nitrate and 1.24g of zirconium nitrate and dissolve in 12.7mL of deionized water, wherein the molar concentration ratio Ce:Zr=1:0.5, configure the first mixed aqueous solution with an ion concentration of 1mol / L, and mix well. Prepare 4mol / L ammonia solution, add the prepared first mixed aqueous solution to 7.65mL ammonia solution at a rate of 2mL / min, adjust pH=9, add polyethylene glycol 0.1g, fully stir, let stand, 70 Aging at ℃ for 12h, drying at 100℃ for 12h after vacuum filtration, and calcining at 500℃ for 5h.

[0025] Dissolve 14.72g of aluminum nitrate in 39.23mL of deionized water, prepare a second aqueous solution with an ion concentration of 1mol / L, add the second aqueous solution dropwise to 21.40mL of 4mol / L ammonia solution, adjust the pH to 10, and add polyethylene glycol 0.1g, aging, drying, roasting, the method is the same as before...

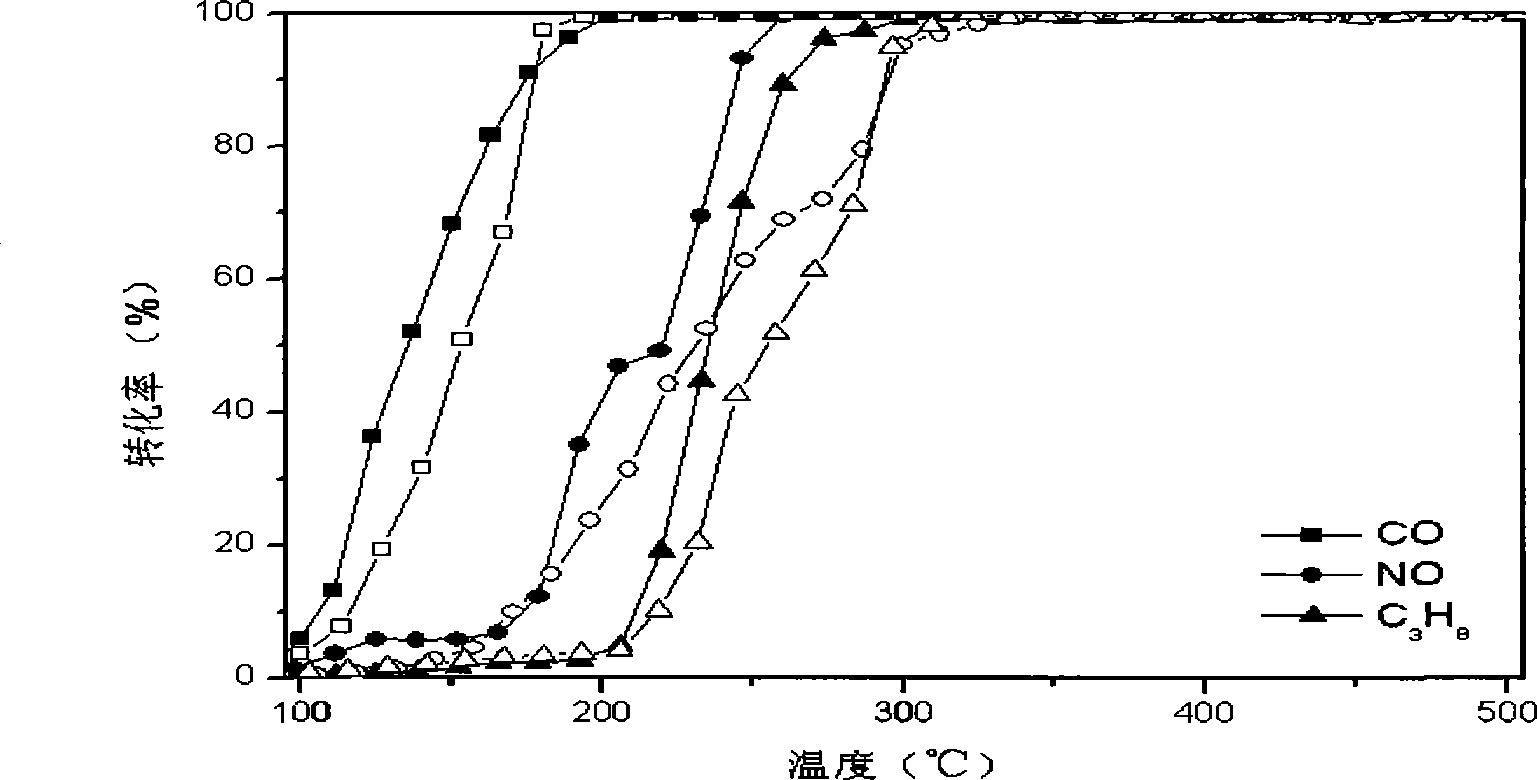

Embodiment 2

[0029] The ratio of CO:NO in the exhaust gas is 0.8%: 1400ppm=5.7, and the air-fuel ratio λ=1.003.

[0030] Take 20.22g of cerium sulfate, 16.96g of zirconium nitrate, and 0.50g of strontium nitrate and dissolve them in 200g of deionized water, wherein the molar concentration ratio Ce:Zr=1:1, the mass fraction of Sr is 3wt.%, and the total ion concentration is 0.5mol / The first aqueous solution of L. Configure 3.5mol / L ammonia solution, add the prepared first mixed aqueous solution to 7.65mL ammonia solution at a rate of 2mL / min, adjust pH=9, add polyethylene glycol 0.1g, stir fully, let stand, Aging at 70°C for 12h, vacuum filtration, drying at 100°C for 12h, and calcination at 500°C for 5h.

[0031] Dissolve 12.66g of aluminum chloride in 63.5g of deionized water, configure a second aqueous solution with an ion concentration of 1.5mol / L, add it to 71.25mL of 3.5mol / L ammonia solution at a rate of 2mL / min, and adjust the pH to 10. Subsequent processing is the same as before...

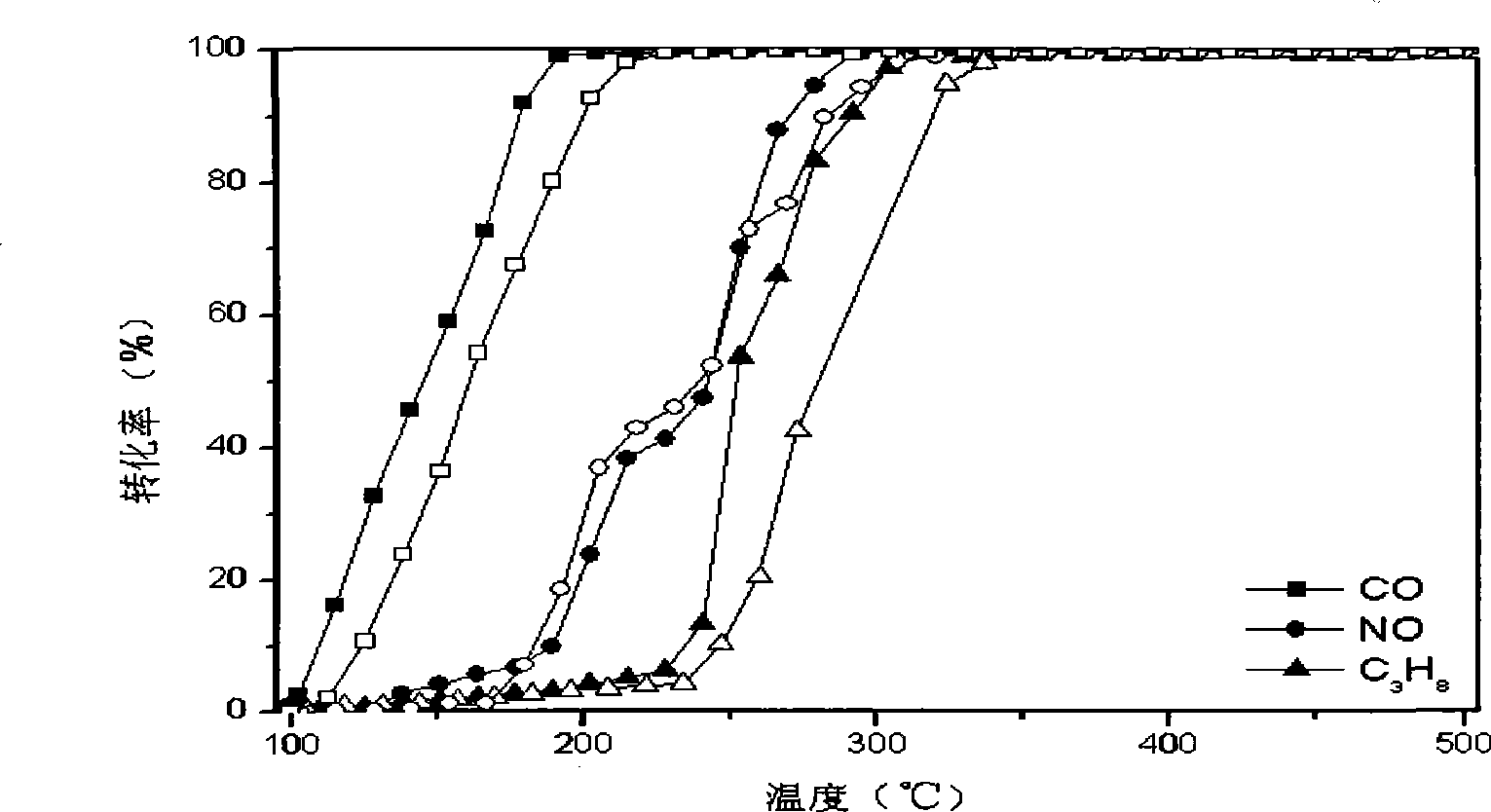

Embodiment 3

[0035] The ratio of CO:NO in the exhaust gas is 1.6%: 950ppm=16.8, and the air-fuel ratio λ=1.000.

[0036] Dissolve 87.64g of cerium ammonium nitrate, 117.92g of zirconium nitrate and 3.80g of copper nitrate in 100g of water, wherein the molar concentration ratio Ce:Zr=1:2, Cu mass fraction is 5% and dissolve in 350g of deionized water to configure the total ion concentration It is the first aqueous solution of 1.5 mol / L. Configure 4.5mol / L ammonia solution, add the prepared first mixed solution to 37.2mL ammonia solution at a rate of 2mL / min, adjust pH=8.5, add polyethylene glycol 0.25g, fully stir, let stand, Aging at 70°C for 12h, vacuum filtration, drying at 100°C for 12h, and calcination at 500°C for 5h.

[0037] Dissolve 53.25g of aluminum chloride in 500g of deionized water, configure a second aqueous solution with an ion concentration of 0.5mol / L, add it to 166.7mL of 4.5mol / L ammonia solution at a rate of 2mL / min, adjust the pH to 10, and then Same as before.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com