Method for preparing colon positioning compression-coated tablets

A colon positioning and chip-packing technology, which is applied in pharmaceutical formulations, medical preparations with inactive ingredients, drug delivery, etc., can solve the problems of early release of drugs, rapid expansion in contact with water, etc., and achieves low price, simple preparation process, A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

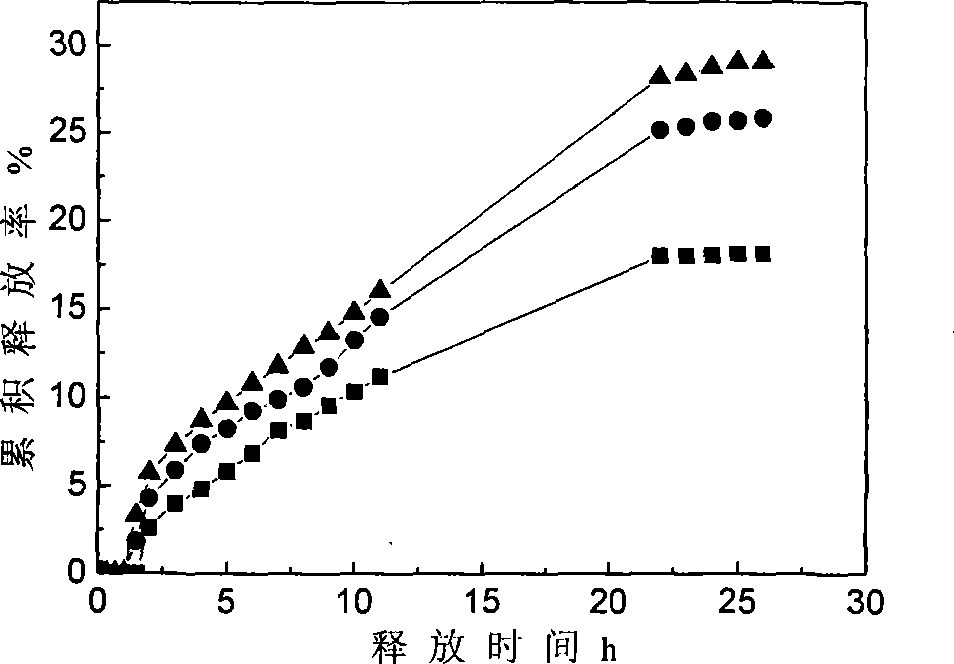

[0024] A method for preparing a colon-positioned compressed package chip, comprising the following steps:

[0025] (1) Preparation of colon-positioned compressed package chip wrapping material: take 40% blended polysaccharide (KGM:XG=7:3) by weight percentage, and mix 60% lactose to obtain mixture 1; will account for mixture 1 weight Add 30% of water into mixture 1 for wet granulation, dry to constant weight, pass through a 20-mesh sieve for granulation; then mix evenly with talcum powder accounting for 1% of the granule weight after granulation, and 3% magnesium stearate to obtain Colon positioning pressing package chip wrapping material;

[0026] (2) Preparation of drug-containing disintegrating tablet core: take 90% raw material drug and 10% sodium starch glycolate by weight percentage, and mix uniformly to obtain mixture 2; add water accounting for 20% by weight of mixture 2 to mixture 2 Wet granulation, drying to constant weight, passing through a 20-mesh sieve for granu...

Embodiment 2

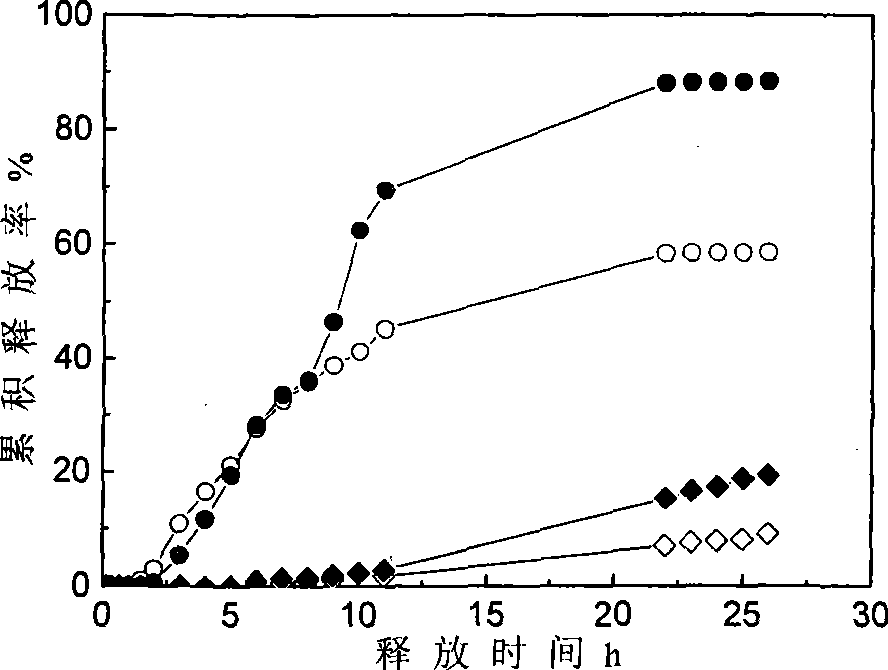

[0030] Prepare three copies of colon-targeted compressed package chips with different proportions of blended polysaccharides, and the preparation steps of each copy are as follows:

[0031](1) Preparation of colon-positioned compression package chip wrapping material: take 40% blended polysaccharide (KGM:XG ratios are 3:7, 5:5 and 7:3 respectively) and 60% lactose by weight percentage Obtain mixture 1 evenly; add water accounting for 30% of the weight of mixture 1 into mixture 1 for wet granulation, dry to constant weight, pass through a 20-mesh sieve for granulation; The magnesium stearate is mixed uniformly to obtain the colon-positioning pressing package chip wrapping material;

[0032] (2) Preparation of drug-containing disintegrating tablet core: take 90% raw material drug and 10% sodium starch glycolate by weight percentage, and mix uniformly to obtain mixture 2; add water accounting for 20% by weight of mixture 2 to mixture 2 Wet granulation, drying to constant weight,...

Embodiment 3

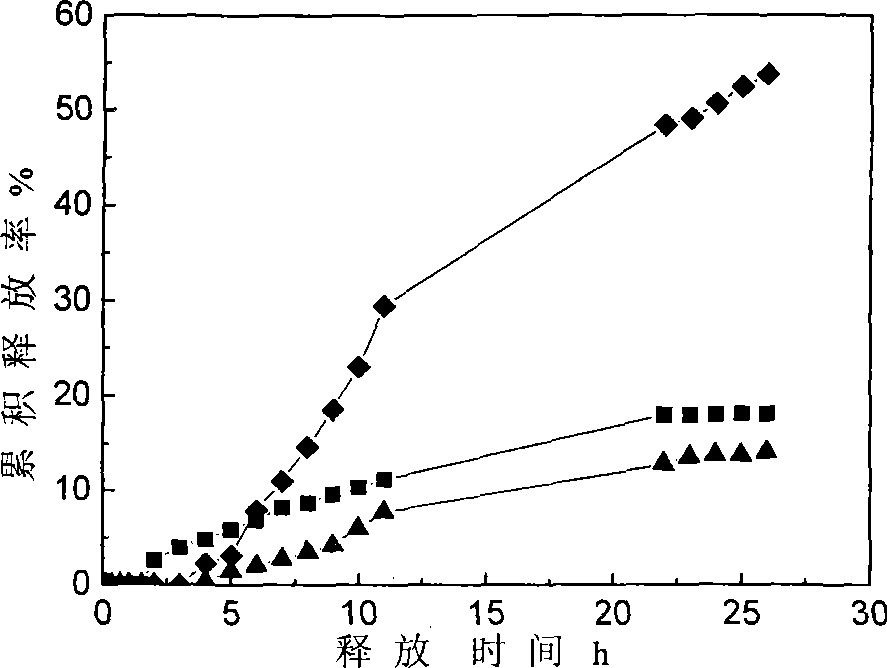

[0038] Prepare three copies of colon-targeted compressed package chips with different lactose contents, and the preparation steps of each part are as follows:

[0039] (1) Preparation of the colon-positioned compression package chip wrapping material: the blended polysaccharide (KGM:XG=3:7) is 40%, 35% and 30% respectively, and the lactose is 60% and 65% respectively according to the weight percentage Mix with 70% evenly to obtain mixture 1; add 30% of the weight of mixture 1 to the mixture 1 for wet granulation, dry to constant weight, pass through a 20-mesh sieve for granulation; and then add 1% of talc powder, and 3% magnesium stearate are mixed evenly to obtain the colon-positioned pressing package chip wrapping material;

[0040] (2) Preparation of drug-containing disintegrating tablet core: take 90% raw material drug and 10% sodium starch glycolate by weight percentage, and mix uniformly to obtain mixture 2; add water accounting for 20% by weight of mixture 2 to mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com