A method for industrial production of biocatalysts in the form of enzymes or microorganisms immobilized in polyvinyl alcohol gel, their use and devices for their production

A polyvinyl alcohol gel and biocatalyst technology, which is applied in the methods of granulating raw materials, chemical instruments and methods, biofuels, etc., can solve the problems of product shape change, mechanical wear of continuous conveyor belts, etc., and reduce the reaction volume. , the effect of reducing operating costs and high reaction rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

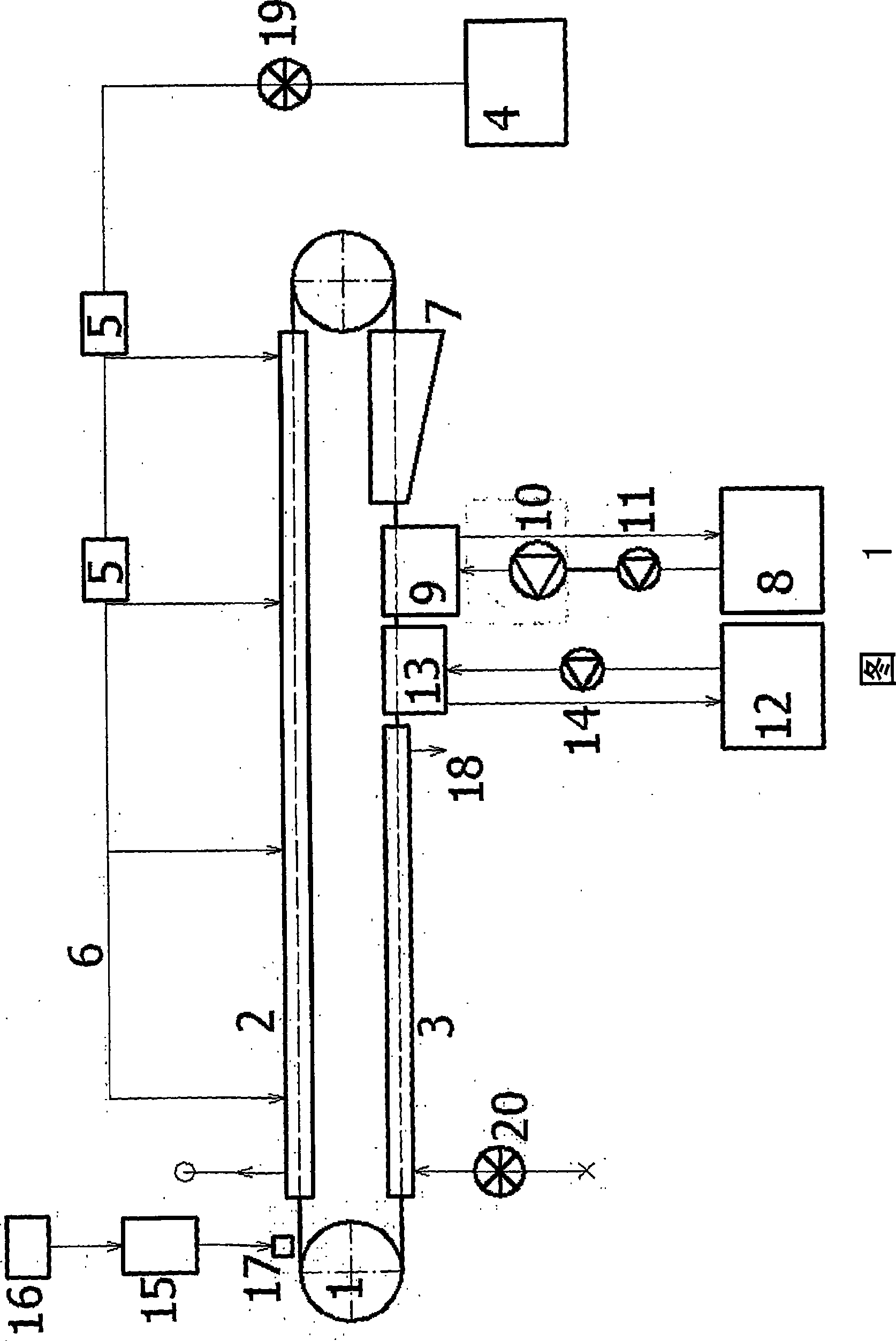

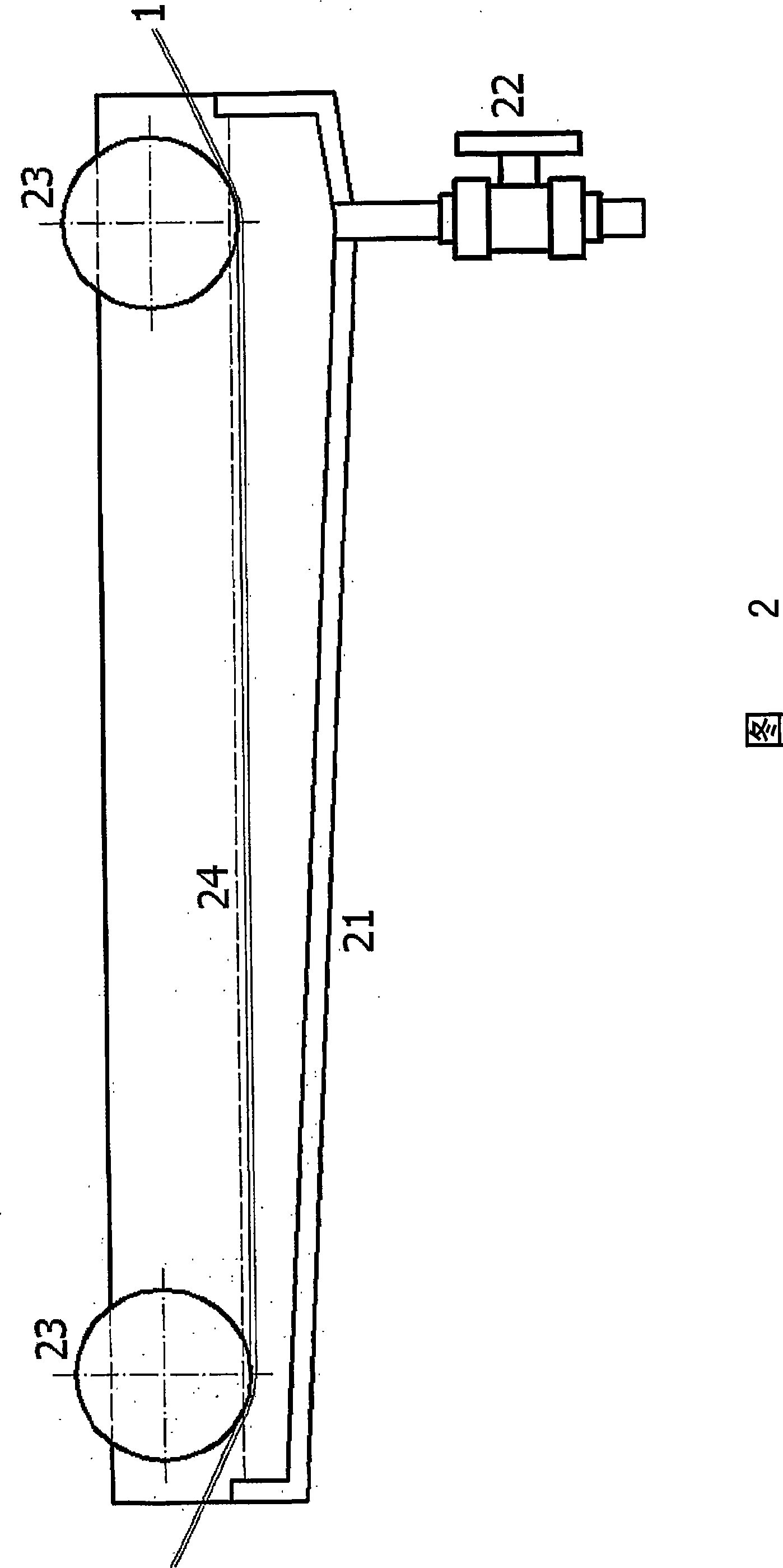

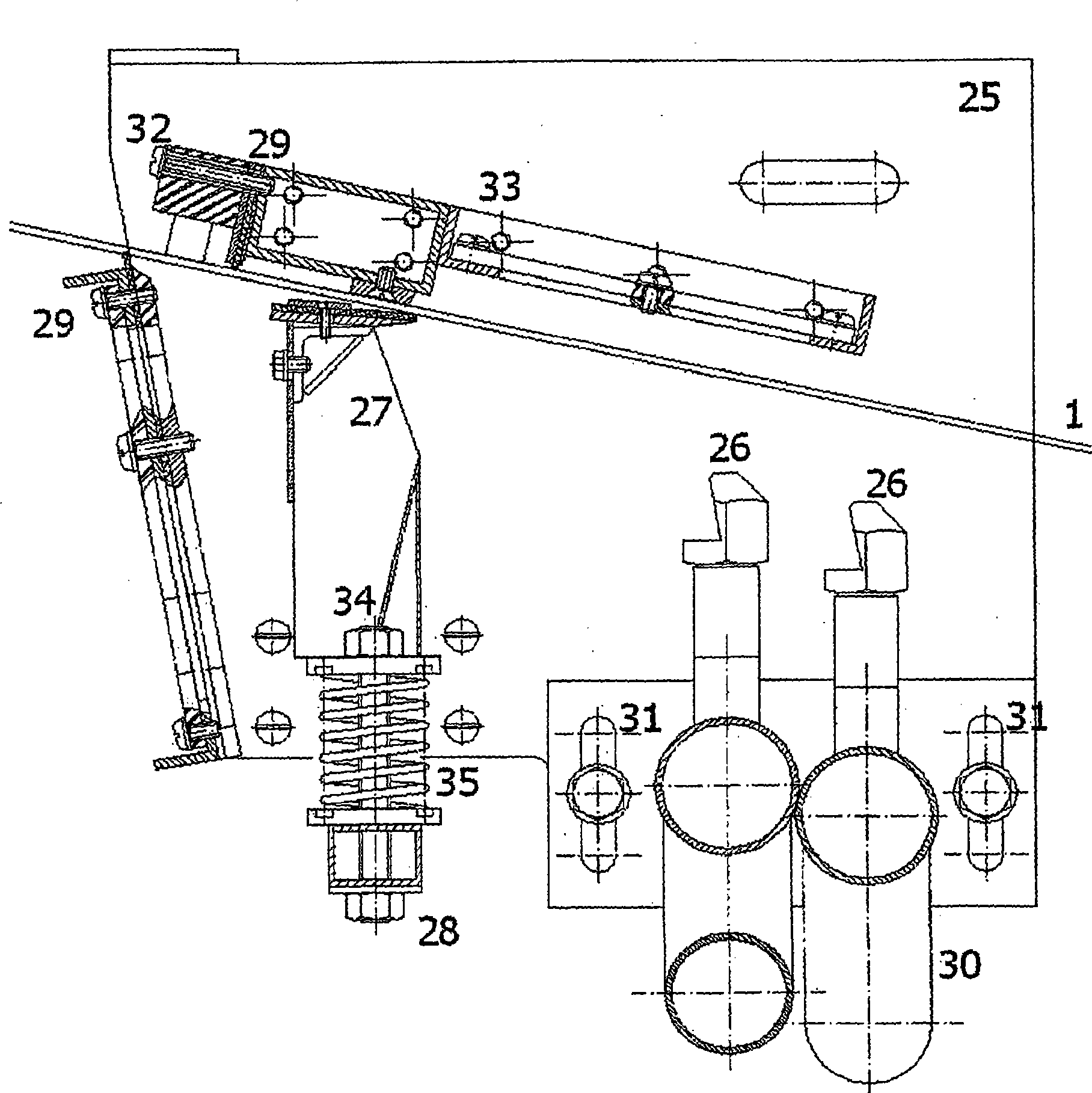

Method used

Image

Examples

Embodiment 1

[0071] Immobilization – biocatalyst for nitrification by embedding pure mixed cultures of nitrifying bacteria (Nitrosomonas europeae and Nitrobacter winogradskiy) in PVA-hydrogel prepared.

[0072] Immobilization - The biocatalyst for denitrification was prepared by entrapment of paraccocus denitrificans.

[0073] The immobilization was carried out according to the following method: a PVA solution containing 100 g of PVA (polyvinyl alcohol), 60 g of PEG (polyethylene glycol), and 790 g of distilled water was prepared. Add 50 ml of homogenized biomass suspension to the prepared solution such that the resulting cell concentration reaches 0.60 g cells / dm 3 gel. The cell mixture in the PVA solution thus prepared was dropped on a rigid plate, then cross-linked and shaped in a stream of dry air at 80°C to 15°C. Make the surface area to volume ratio not less than 7mm -1 The immobilized substance was transferred to a solution of sodium sulfate (0.01 mol / l) and ammonium chloride (0...

Embodiment 2

[0079] Immobilized substances prepared and cultured as described in Example 1 above were used in a continuously regulated mode of nitrification and denitrification to remove nitrogen pollution from real wastewater containing high concentrations of nitrogen pollution (200 mg / l to 1000 mg / l N- NH 4 ) and actually has a dichromate value of 0.

[0080] A continuous mode unit was used to detect simultaneous nitrification and denitrification, with an effective volume of 17 L for the oscillatory nitrification reactor and 3.8 L for the oscillatory denitrification reactor. The flow rate of actual industrial wastewater is 35 liters / day, where N-NH 4 The content is 1600mg / l.

[0081] 2000 g of biocatalyst containing embedded nitrifying bacteria was added to the nitrification reactor. 800 g of biocatalyst containing embedded denitrifying bacteria was added to the denitrification reactor.

[0082] In the case of 95% nitrification efficiency, the average nitrification rate is about 1000...

Embodiment 3

[0084] Immobilized substances prepared and cultured as described in Example 1 above were used in a regulated mode of continuous nitrification and denitrification to remove nitrogen pollution from real wastewater containing high concentrations of nitrogen pollution (200 mg / l to 1000 mg / l N -NH 4 ) and high dichromate values (>1000mg / l).

[0085] The prepared immobilized products were subjected to batch fermentation. In a working volume of 17 liters containing 15 liters of synthetic wastewater (WW) containing approximately 800 mg / l N-NH 4 and 2000g of biocatalyst containing embedded nitrifying bacteria), the nitrification process (removal of nitrogen from ammonia water) was completed after 12 hours, which means that the nitrification rate was about 500mg N-NH 4 / hour x kg biocatalyst, equivalent to about 1.6kg N-NH respectively 4 / m 3 WW x days and 12kg N-NH 4 / m 3 Biocatalyst x number of days.

[0086] In an effective volume of 15.8 liters, containing 15 liters of synt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com