Solder convex point connected metal layer in microelectronic package and use thereof

A technology of microelectronic packaging and metallization layer, which is applied in the field of micro-interconnection, can solve the problems of accelerated reaction rate between metallization layer and solder, lower connection reliability, and consumption of metallization layer, so as to achieve good mechanical reliability and improve use The effects of life, safety and reliability, and stable interface reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

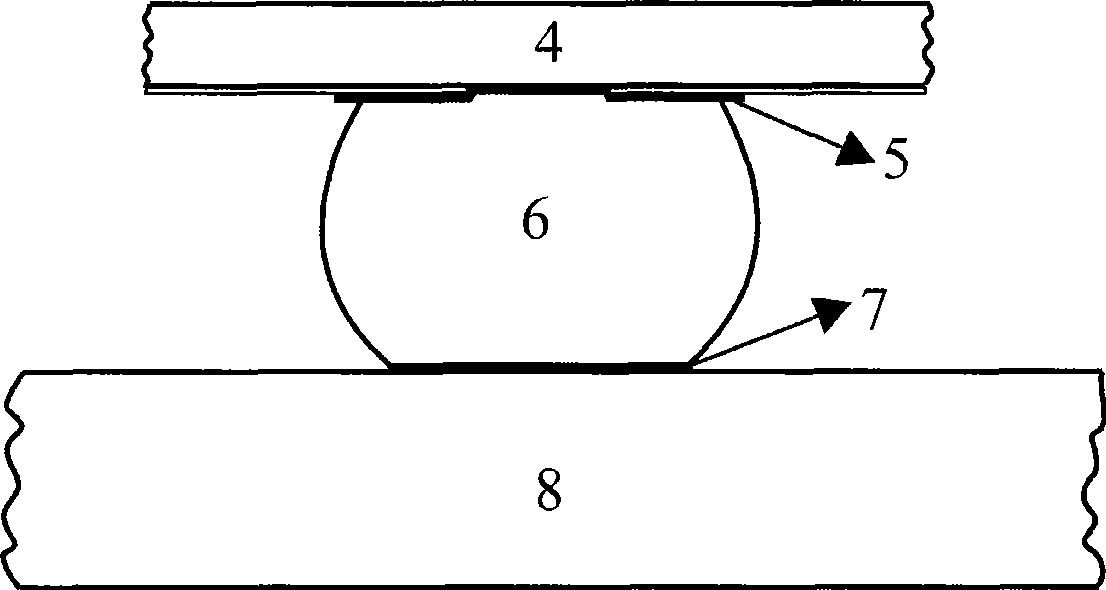

[0035] An iron-nickel alloy is electroplated or electrolessly plated on the surface of a conductive substrate such as copper or nickel, or on the surface of a non-conductive substrate covered by a conductive film. The composition and thickness of the electroplated layer can be adjusted according to actual requirements. Such as figure 1 As shown, the plating layer realized by the present invention can be used as the pad metallization layer 7 on the substrate and the printed circuit board 8 and the lower metallization layer 5 of the solder bump 6 in the flip-chip solder connection of the chip 4. Such as figure 2 As shown, the macro cross-sectional view of the iron-nickel plating / tin-silver-copper spherical bump connector.

[0036] A thin iron-nickel layer is plated on the copper substrate by electroplating. Its composition is: iron 57%, nickel 42%, and the rest are unavoidable impurities such as phosphorus (weight percentage). The surface of the plating layer is cleaned with an ac...

Embodiment 2

[0040] The difference from Example 1 is that, in terms of percentage by weight, the composition of the iron-nickel layer is: iron 30%, the balance is nickel and unavoidable impurities, and the unavoidable impurities are below 1% by weight.

Embodiment 3

[0042] The difference from Example 1 is that, in terms of percentage by weight, the composition of the iron-nickel layer is 40% iron, the balance is nickel and unavoidable impurities, and the unavoidable impurities are below 1% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com