System for recovering sensible heat of blast furnace slag

A technology for sensible heat recovery and blast furnace slag, which is applied in the direction of recovery and utilization technology, improvement of process efficiency, steam generation method using heat carrier, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

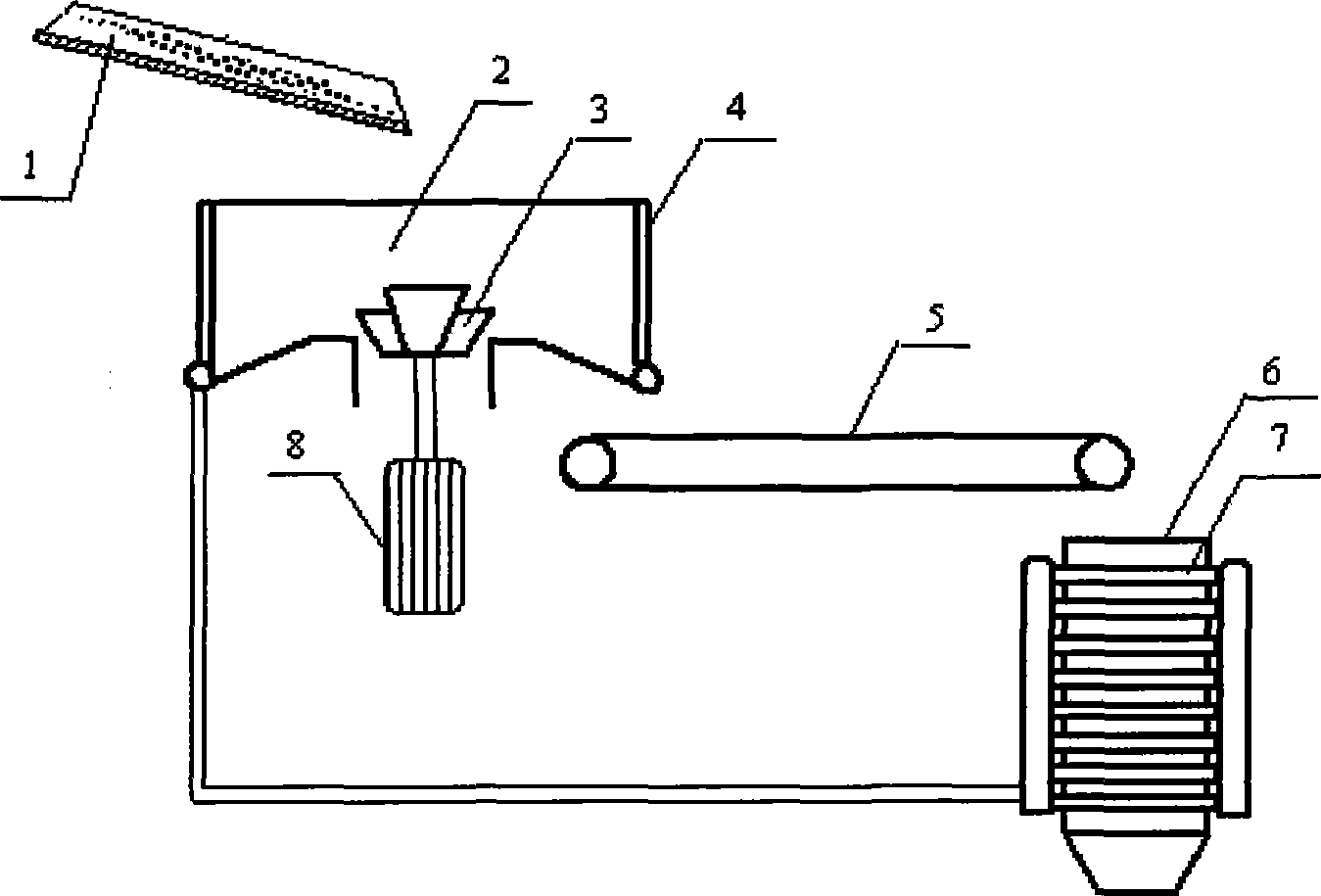

[0017] Embodiment 1: as figure 1 Shown is a schematic structural diagram of the present invention: a slag particle catcher 2 is installed below the slag flow tank 1, the slag particle catcher 2 is cylindrical, and a double-layer rotor cup 3 is arranged in the middle of the slag particle catcher 2 , the double-layer rotor cup 3 is connected with the motor 8, after the high-temperature liquid slag enters the double-layer rotor cup 3 with a speed of 1500 rpm from the slag launder 1, it is thrown out along the tangential direction of the double-layer rotor cup 3, during this process The slag is broken into slag particles with a diameter of less than 10 mm. The surface of the broken slag particles starts to solidify during flight, and finally hits the water wall 4 of the slag particle catcher 2. The slag particles are crushed on the water wall 4. It is further cooled and completely solidified, then slides down to the bottom of the slag particle trap 2, then falls onto the slag conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com