Cutting wire production method and cutting wire and tyre cutting device

A manufacturing method and technology of cutting device, which are applied in manufacturing tools, metal processing equipment, metal processing and other directions, can solve the problems such as difficulty in making bead saws too small, low lifespan of diamond wire saws, high noise and smoke pollution, etc. Small cutting force, fast cutting speed and wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

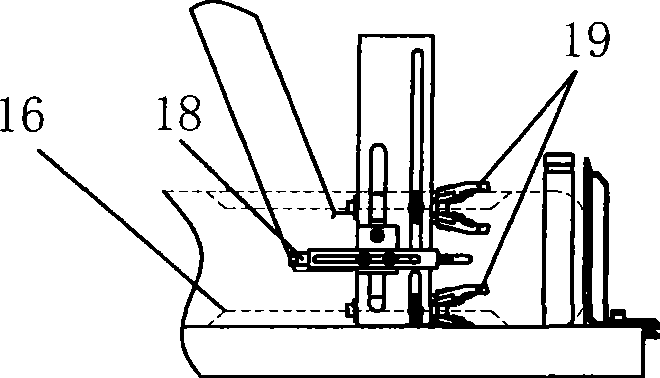

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] see Figure 4 , Figure 5 , an embodiment of the method for making a cutting wire of the present invention is to manufacture a cutting wire with a length of 1 m and a diameter of about 2 mm as an example. Cut out a steel wire rope 20 with a diameter of φ2mm and a length of about 1m. After alkali cleaning, degreasing and acid cleaning, the steel wire rope 20 is insulated and wrapped in segments with PVC plastic film, so that the wrapped part is insulated and no metal is deposited in the subsequent electroplating process. Binder to maintain the flexibility of the wire rope cutting wire. The width of the bandaged part is about 15mm, and the width of the unbandaged part is also about 15mm. Then, the steel wire rope 20 is pre-plated with a Watt-type nickel plating solution to form a transition layer 23 , the transition layer 23 can improve the bind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com