Cobaltiferous aluminum alloy material and preparation thereof

A technology of aluminum alloy materials and alloy components, applied in the field of aluminum alloy materials, can solve the problems of general heat treatment hardenability and other problems, and achieve the effects of improving heat treatment hardenability, heat treatment hardenability and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Al-6.2Zn-2.5Mg-1.9Cu-0.14Zr-0.07Co (wt%) alloy was prepared by ingot metallurgy. The raw materials used are high-purity aluminum, industrial pure magnesium, industrial pure zinc, aluminum-copper master alloy, magnesium-zirconium master alloy, and aluminum-cobalt master alloy. The melting furnace is a resistance heating furnace, and the casting machine is a vertical semi-continuous casting machine. The melting and casting process adopted is: furnace loading (putting high-purity aluminum into the melting furnace) → melting (adding industrial pure zinc, aluminum-copper master alloy, magnesium-zirconium master alloy, and aluminum-cobalt master alloy into the melting furnace, and then melting)→ Slag removal→processing industrial pure magnesium (adding industrial pure magnesium into the melting furnace)→stirring→sampling for component analysis→adjusting components→stirring→refining (725°C)→slagging→standstill (10 minutes)→casting, among which, The casting temperature is 705°...

Embodiment 2

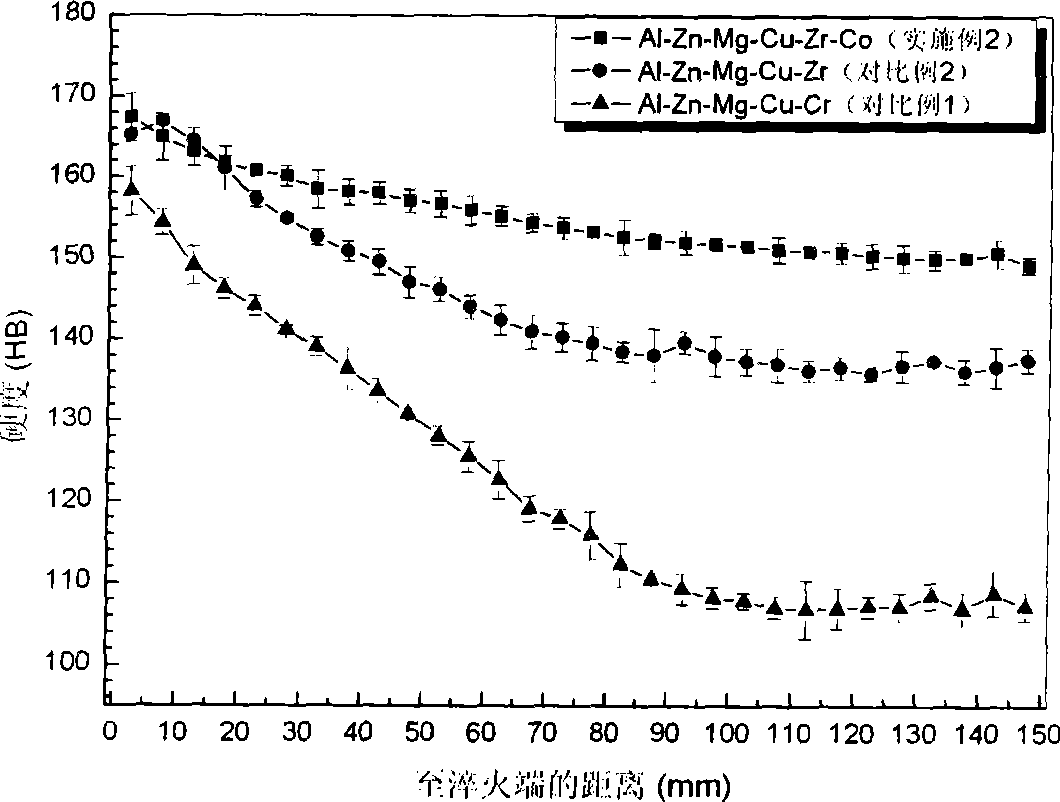

[0046] Al-6.2Zn-2.5Mg-1.9Cu-0.14Zr-0.11Co (wt%) alloy was prepared by ingot metallurgy. The raw materials used are high-purity aluminum, industrial pure magnesium, industrial pure zinc, aluminum-copper master alloy, magnesium-zirconium master alloy, and aluminum-cobalt master alloy. The melting furnace is a resistance heating furnace, and the casting machine is a vertical semi-continuous casting machine. The melting and casting process adopted is: furnace loading (putting high-purity aluminum into the melting furnace) → melting (adding industrial pure zinc, aluminum-copper master alloy, magnesium-zirconium master alloy, and aluminum-cobalt master alloy into the melting furnace, and then melting)→ Slag removal→processing industrial pure magnesium (adding industrial pure magnesium into the melting furnace)→stirring→sampling for component analysis→adjusting components→stirring→refining (725°C)→slagging→standstill (10 minutes)→casting, among which, The casting temperature is 705°...

Embodiment 3

[0048] Al-6.2Zn-2.5Mg-1.9Cu-0.14Zr-0.25Co (wt%) alloy was prepared by ingot metallurgy. The raw materials used are high-purity aluminum, industrial pure magnesium, industrial pure zinc, aluminum-copper master alloy, magnesium-zirconium master alloy, and aluminum-cobalt master alloy. The melting furnace is a resistance heating furnace, and the casting machine is a vertical semi-continuous casting machine. The melting and casting process adopted is: furnace loading (putting high-purity aluminum into the melting furnace) → melting (adding industrial pure zinc, aluminum-copper master alloy, magnesium-zirconium master alloy, and aluminum-cobalt master alloy into the melting furnace, and then melting)→ Slag removal→processing industrial pure magnesium (adding industrial pure magnesium into the melting furnace)→stirring→sampling for component analysis→adjusting components→stirring→refining (725°C)→slagging→standstill (10 minutes)→casting, among which, The casting temperature is 705°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com