Hydrogen-oxygen combustion-supporting horizontal boiler

A horizontal boiler, hydrogen and oxygen technology, applied in the field of boilers, can solve the problems of less combustion-supporting measures, large smoke and dust emissions, poor effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

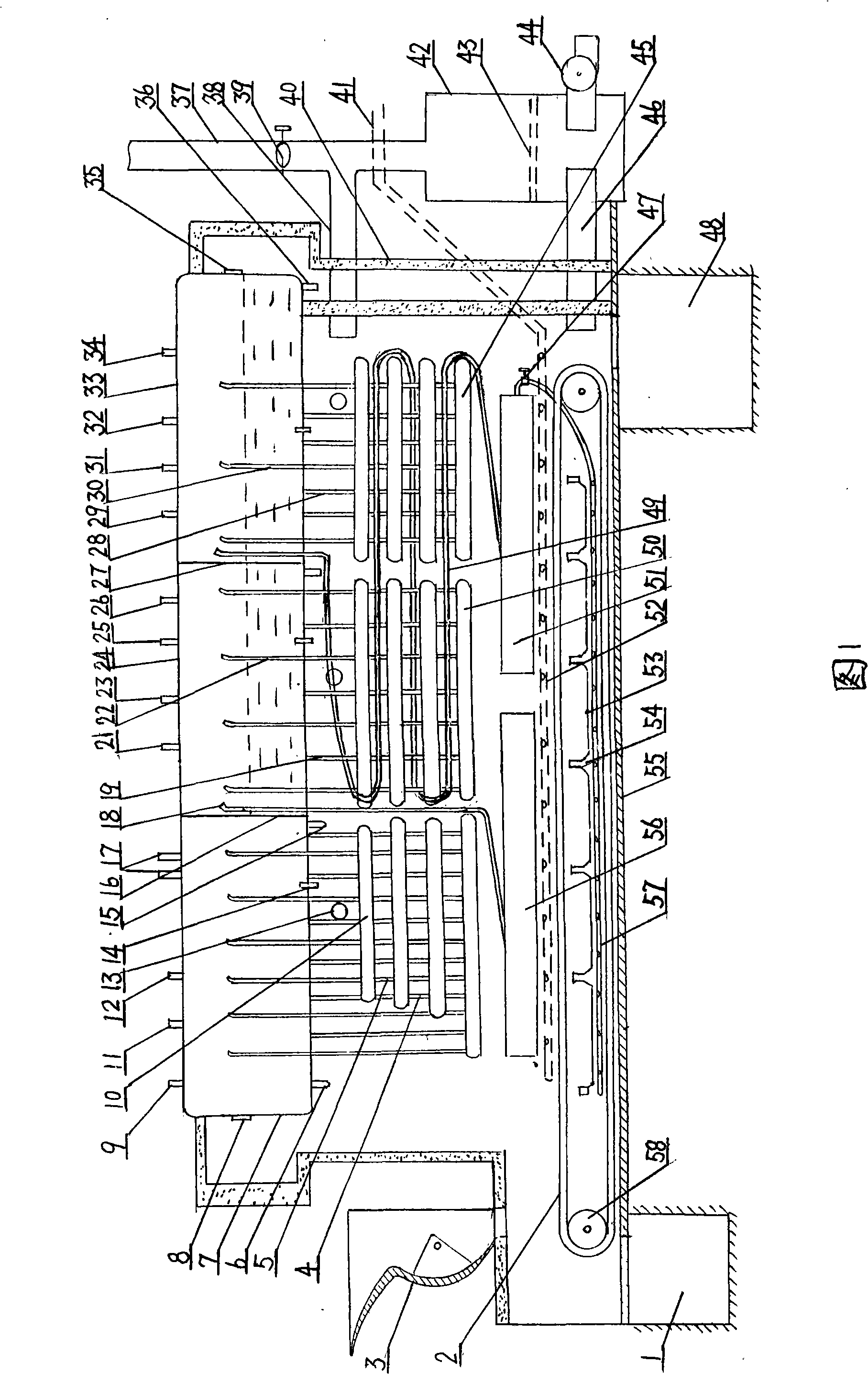

[0007] The following embodiments illustrate the structure and working principle of the present invention in conjunction with the accompanying drawings.

[0008] As shown in the drawings, the hydrogen-oxygen combustion-supporting horizontal boiler of the present invention has a furnace outer wall 40, a heating water tank 7 and a combustion-supporting water tank 33 are installed on the upper part of the furnace outer wall, a base 55 is arranged at the bottom, and a fire grate 2 is installed on the upper part of the base. On the runner 58, there are hot water pipes 5 and cold water pipes 4 in communication with the heat exchange pipes 10 below them on the heating water tank respectively. The hot water pipes are higher than the cold water pipes. The lower heat exchange tubes 45 are connected, the upper end of the steam heating coil 49 is located in the heating water tank, and the lower end is connected to the pyrolysis gas collecting pipe 51. On the gas collecting pipe, there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com