Method for processing waste water of circulating marine culture by using artificial wet land

A technology for artificial wetlands and marine aquaculture, applied in aerobic and anaerobic process treatment, sustainable biological treatment, chemical instruments and methods, etc., to achieve the effect of improving removal effect, improving denitrification capacity, and improving denitrification capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

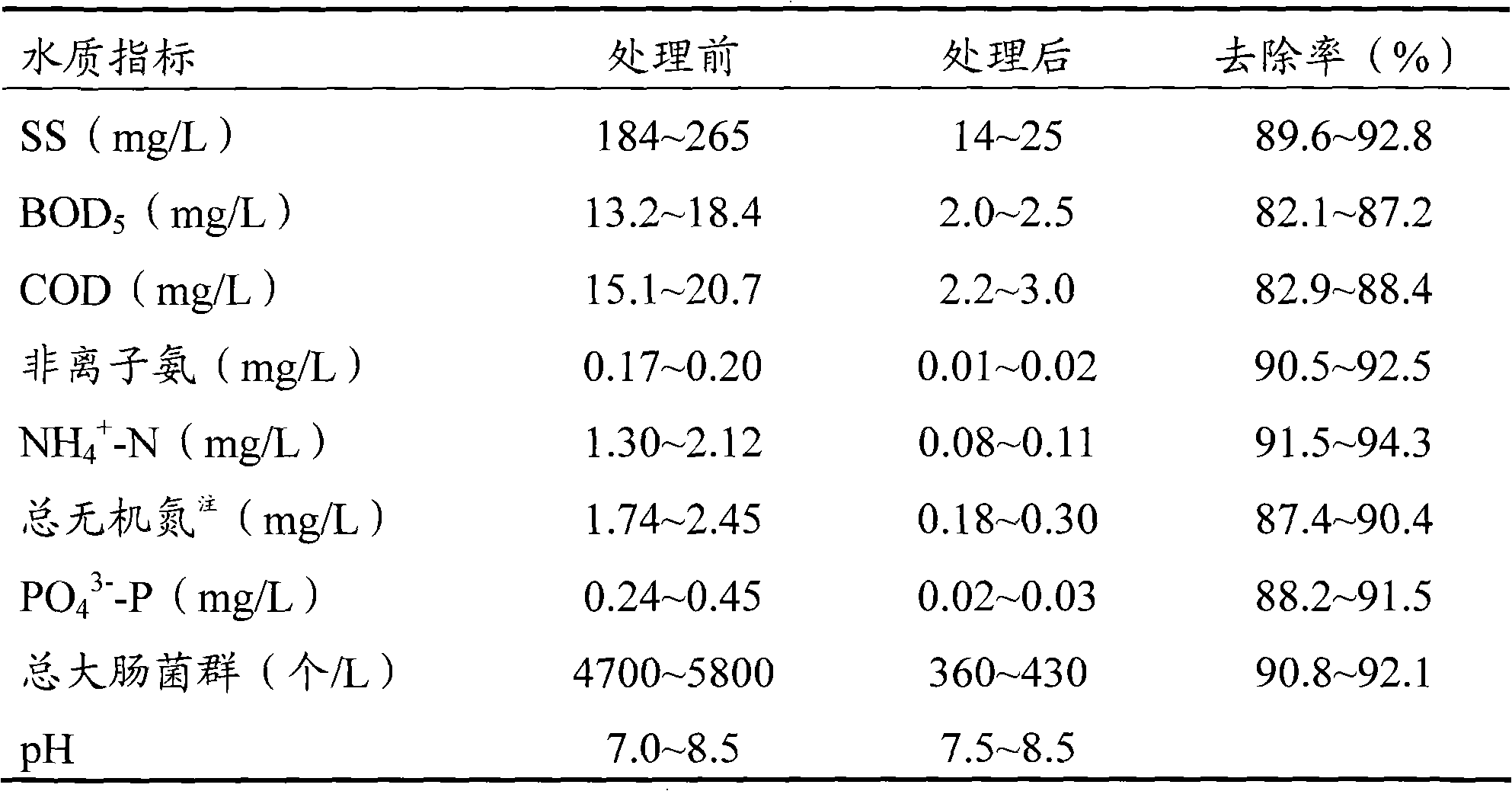

[0019] Take the effluent from a circulating marine aquaculture pond, filter it through a microfiltration machine, and then put it into a horizontal subsurface flow salt-tolerant artificial wetland for treatment, with a daily flow rate of 0.6-1m 3 / d. Sewage is poured into the artificial wetland packing bed from the gravel cloth ditch, infiltrated along the subsurface flow of the matrix, and flows out from the outlet ditch at the other end. After collection, part of the effluent is circulated back to the water inlet and mixed with the influent water. The internal circulation water and microfiltration The volume ratio of water discharged from the machine to the constructed wetland is 2:1, that is, 2 / 3 of the total water inflow to the constructed wetland is effluent from the constructed wetland. During the process of sewage flowing through the constructed wetland, various methods such as matrix filtration, adsorption, precipitation, ion exchange, plant absorption, and microbial m...

Embodiment 2

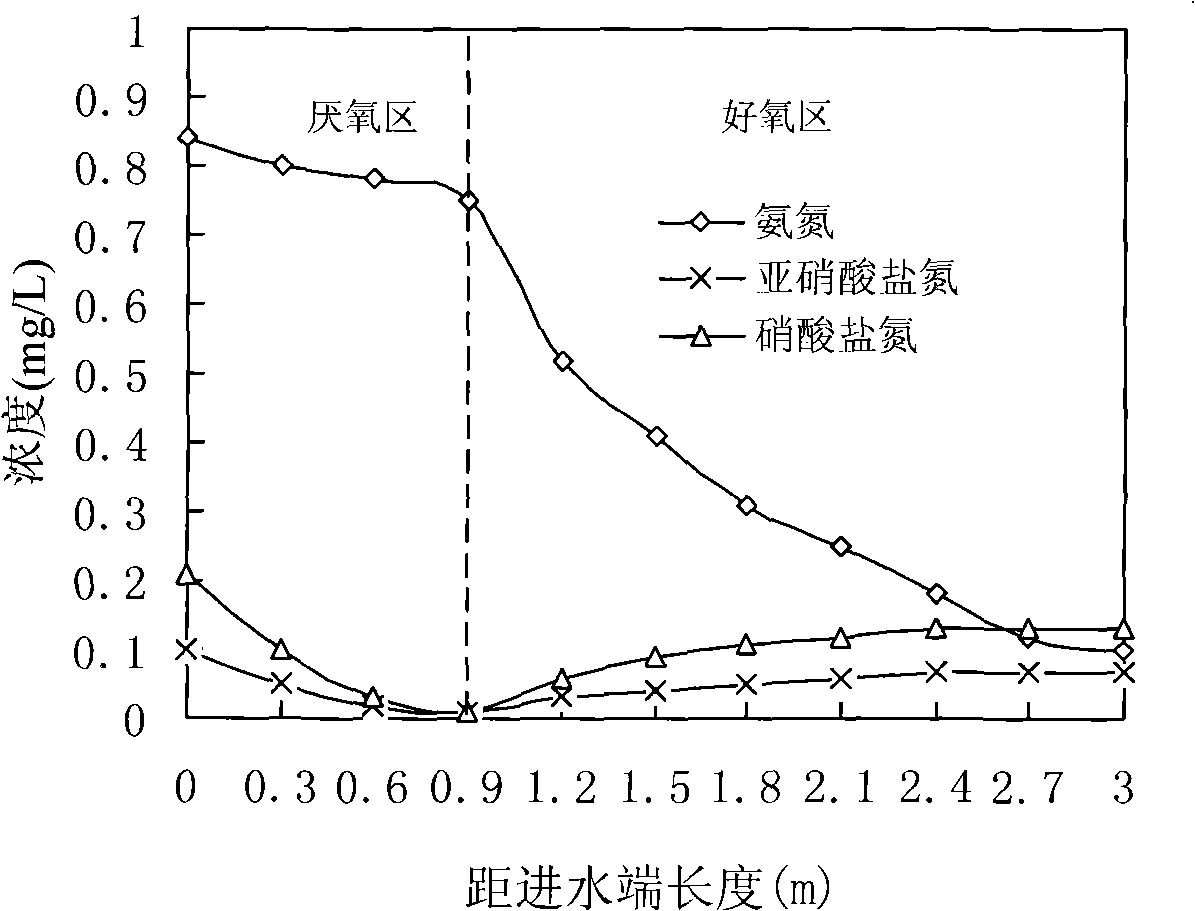

[0026] Take the effluent from a circulating mariculture pond, the water quality index SS is 150-200mg / L, BOD 5 12~15mg / L, non-ionic ammonia 0.15~0.20mg / L, NH 4 + -N is 1.0-2.5mg / L, and the pH value is 6.8-8.0. After being filtered by a microfiltration machine, it is put into a horizontal subsurface flow salt-tolerant artificial wetland for treatment, with a daily flow rate of 0.5-1.5m 3 / d. The designed size of the constructed wetland packing bed is 3m×2m×0.7m in length×width×height, and it is divided into two regions with the anaerobic zone in front and the aerobic zone in the back. The length is 2.4m. The artificial mixed matrix in the anaerobic zone of the packed bed is composed of blast furnace steel slag and fly ash in a volume ratio of 3:1, without providing oxygen, making it an anaerobic environment. The artificial mixed matrix in the aerobic zone of the packed bed is composed of the main material and the auxiliary material in a ratio of 6:1 by volume, wherein the ...

Embodiment 3

[0028] Take the effluent from a circulating mariculture pond, the water quality index SS is 180-300mg / L, BOD 5 17~25mg / L, non-ionic ammonia 0.25~0.40mg / L, NH 4 + -N is 2.0-2.8mg / L, and the pH value is 6.6-8.0. After being filtered by a microfiltration machine, it is put into a horizontal subsurface flow salt-tolerant artificial wetland for treatment, with a daily flow rate of 0.5-1.5m 3 / d. The designed size of the constructed wetland packing bed is 3m×2m×0.7m in length×width×height, and it is divided into two regions with the anaerobic zone in front and the aerobic zone in the back. The anaerobic zone is 1.2m long and the aerobic zone is The length is 1.8m. The artificial mixed matrix in the anaerobic zone of the packed bed is composed of blast furnace steel slag and fly ash at a volume ratio of 10:1, and does not provide oxygen, making it an anaerobic environment. The artificial mixed matrix in the aerobic zone of the packed bed is composed of the main material and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com