Method for synthesizing 4A molecular sieve drier using kaoline

A kaolin and desiccant technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problem of less research on desiccants, and achieve static water adsorption rate, high crush resistance, and good dispersibility. , the effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

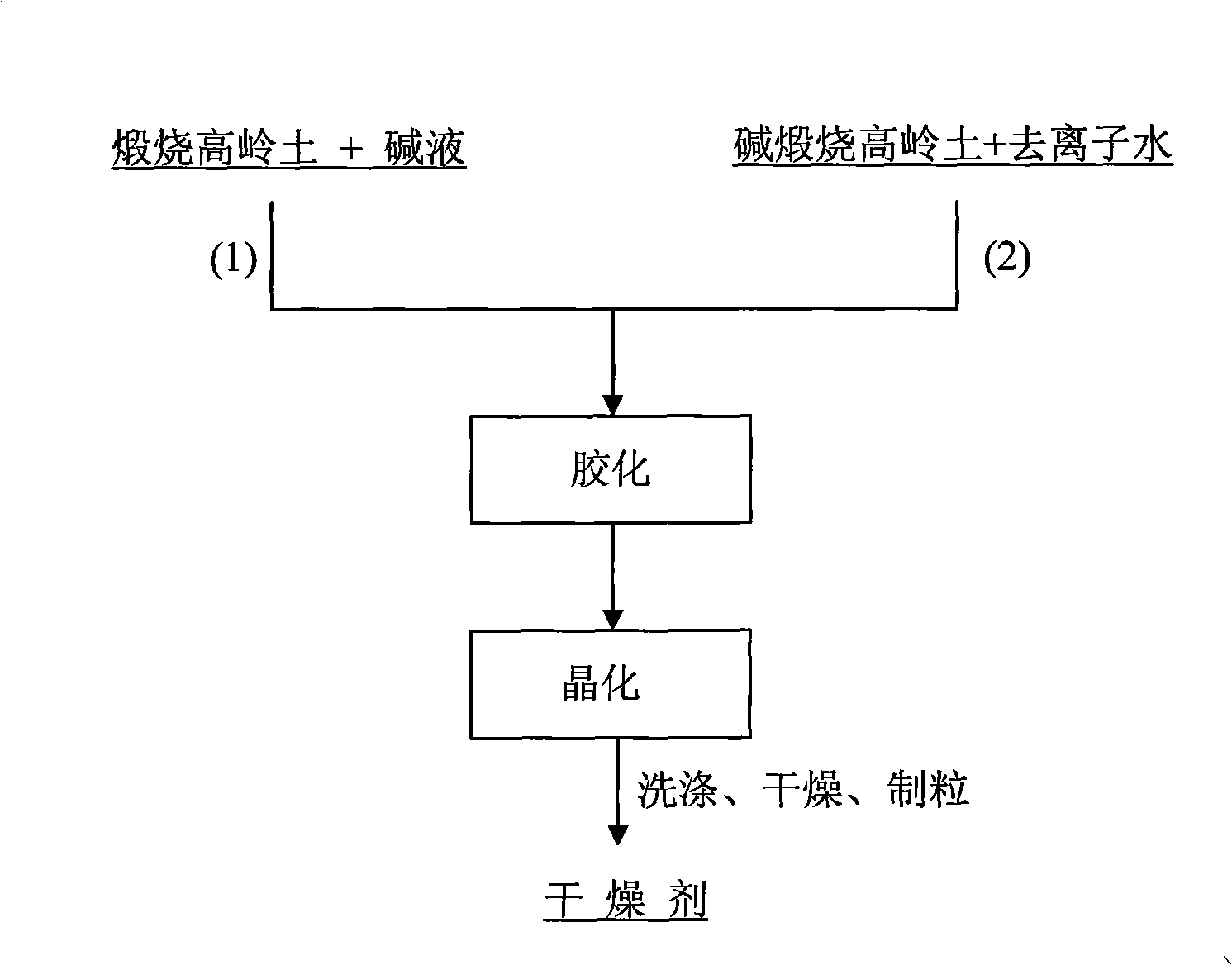

[0037] The kaolin raw material (SiO 2 / Al 2 o 3 The molar ratio is 2.10) into the 3.2mol / L NaOH solution (Na 2 O / SiO 2 The molar ratio is 1.5), gelation at 60°C for 3 hours, crystallization at 95°C for 4 hours, deionized water for suction filtration and washing, the pH of the filtrate is controlled at about 10.0, and the obtained product is dried at 120°C to obtain 4A molecular sieve powder. Clay mineral bentonite, which accounts for 25% by weight of the molecular sieve, is mixed and granulated. The desiccant granules are dried at room temperature and calcined at 550°C to obtain the finished desiccant product KZ-1. The specific experimental procedure is as figure 1 As shown, the synthetic 4A zeolite molecular sieve XRD pattern is as follows figure 2 As shown, the scanning electron microscope with different magnifications such as image 3 Table 1 shows the static water adsorption rate (wt%) and compressive strength (N / particle) of the desiccant.

Embodiment 2

[0039] The kaolin raw material (SiO 2 / Al 2 o 3 The molar ratio is 2.30, and the amount of alkali is used to control Na 2 O / SiO 2The molar ratio is 1.5) After grinding, add it to 150ml deionized water, gelatinize at 60°C for 2h, crystallize at 95°C for 3h, filter and wash with deionized water, control the pH value of the filtrate at about 10.0, and bake the product at 120°C Dry to get 4A molecular sieve powder. Clay mineral bentonite, which accounts for 25% by weight of the molecular sieve, is mixed and granulated. The desiccant granules are dried at room temperature and calcined at 700°C to obtain the finished desiccant product KZ-33. XRD pattern of synthetic 4A zeolite molecular sieve Figure 4 As shown, the scanning electron microscope with different magnifications such as Figure 5 Table 1 shows the static water adsorption rate (wt%) and compressive strength (N / particle) of the desiccant.

Embodiment 3

[0041] The kaolin raw material (SiO 2 / Al 2 o 3 The molar ratio is 2.22, and the amount of alkali used is Na 2 O / SiO 2 The molar ratio is 1.5) After grinding, add it to 150ml deionized water, gelatinize at 60°C for 2h, crystallize at 95°C for 3h, filter and wash with deionized water, control the pH value of the filtrate at about 13.0, and bake the product at 80°C Dry to get 4A molecular sieve powder. Clay mineral bentonite, which accounts for 25% by weight of the molecular sieve, is mixed and granulated. The desiccant granules are dried at room temperature and calcined at 700°C to obtain the finished desiccant product KZ-35. Table 1 shows the static water adsorption rate (wt%) and compressive strength (N / particle) of the desiccant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com