Solid sheet type tantalum electrolyte capacitor and its manufacturing method

A technology for tantalum electrolytic capacitors and manufacturing methods, applied in the direction of solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., to achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

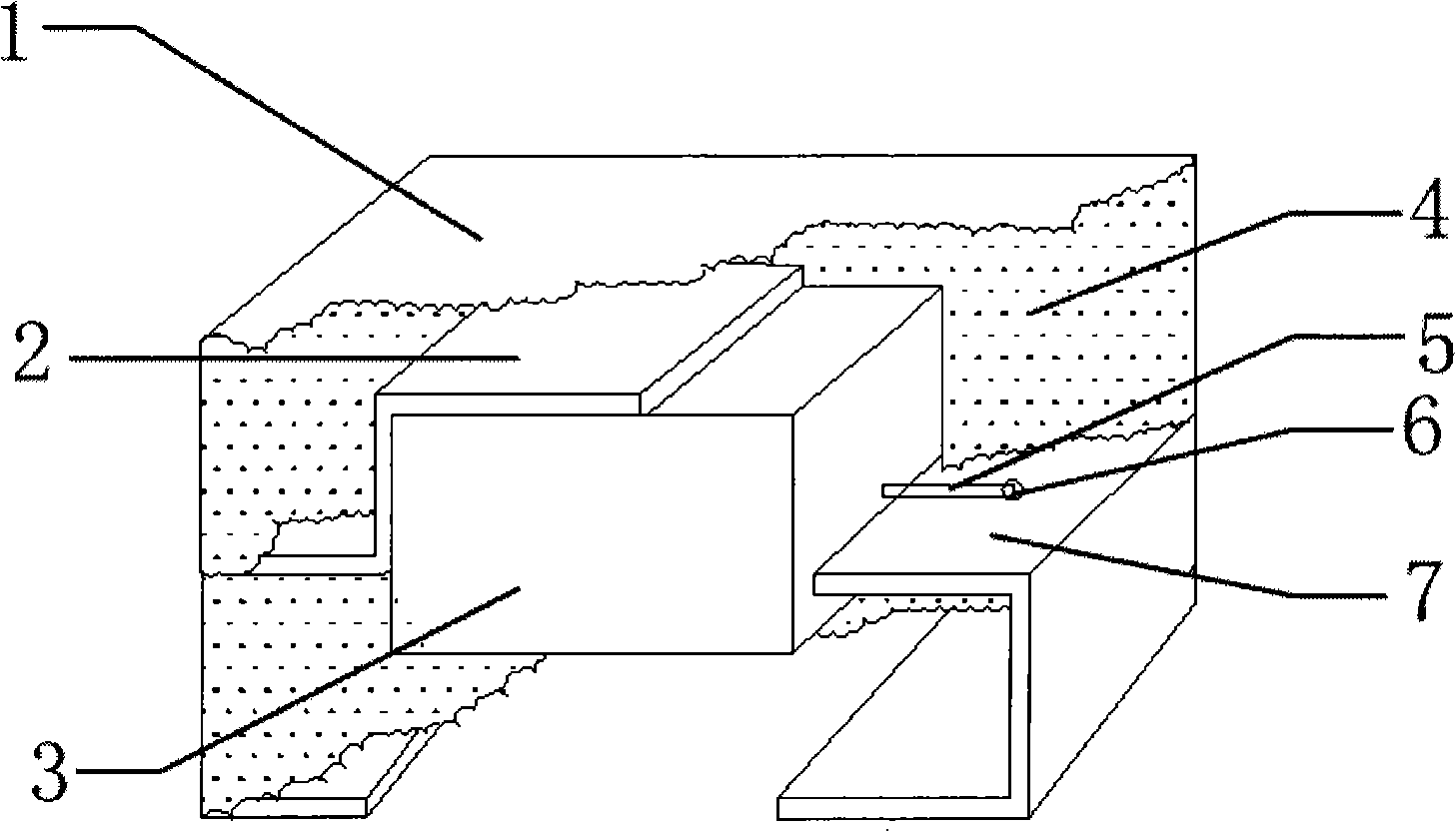

[0036] The embodiment of the present invention provides a solid chip tantalum electrolytic capacitor, the rated withstand voltage of the capacitor can reach 63v, the structure of the capacitor is as follows figure 2 shown, including:

[0037]A tantalum particle capacitor base 3, a nickel-based tin-plated negative electrode lead-out piece 2 and a nickel-based tin-plated anode lead-out piece 7 are arranged in the epoxy resin package shell 1. The inside of the tantalum particle capacitor base 3 is an anode, and the surface is a cathode. A dielectric layer with a thickness of not less than 3500 microns ( figure 2 not shown in), the anode is provided with a tantalum wire lead-out wire 5, the cathode of the tantalum particle capacitor base 3 is electrically connected to the nickel-based tin-plated negative electrode lead-out sheet 2, and the tantalum wire lead-out wire 5 in the tantalum particle capacitor base 3 is welded on the nickel An electrical connection is formed on the ba...

Embodiment 2

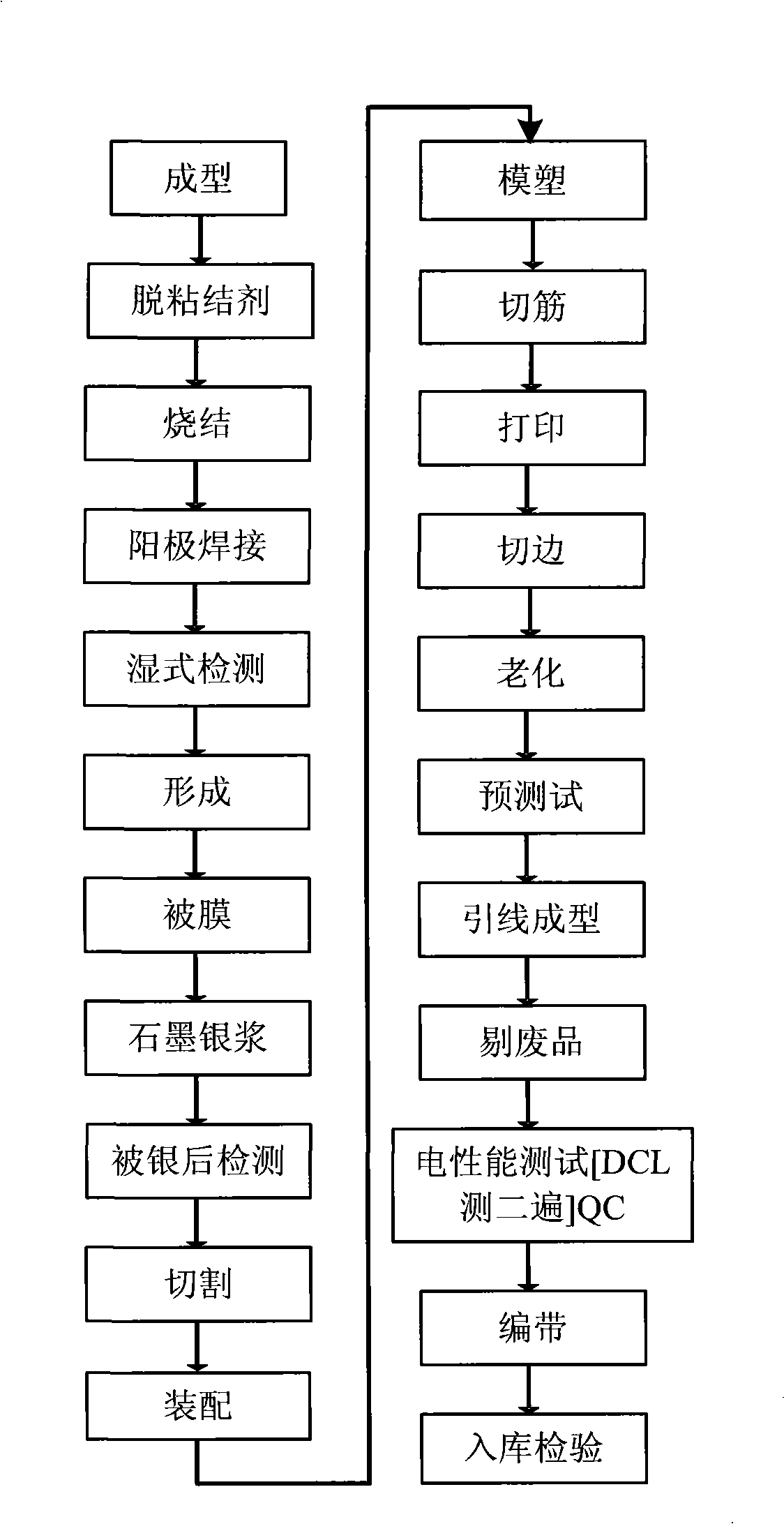

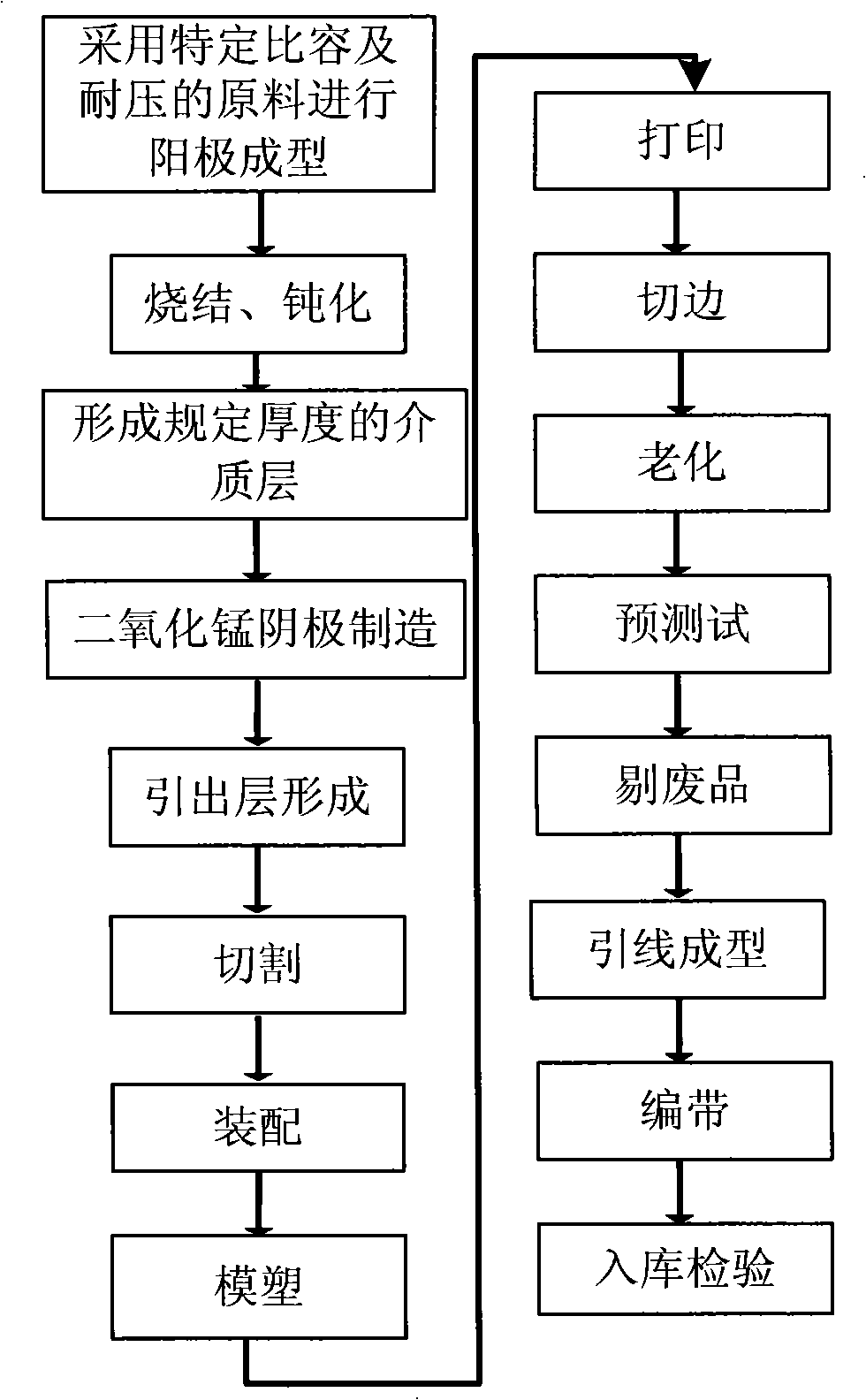

[0053] This embodiment provides a method for manufacturing a solid chip tantalum electrolytic capacitor, specifically as follows:

[0054] Select flaked tantalum powder with a specific volume of 7000UuF.v / g and a breakdown voltage of 240V, press the powder into an anode block with a tantalum wire lead-out wire of a certain size and quality according to a pressing density of 6.5 g / CC, Then carry out vacuum sintering under the conditions of 1700°C temperature and vacuum degree of 5×0.0004Pa to ensure that the strength, density and specific volume of the anode reach the design value;

[0055] The anode block is welded on the stainless steel bar, at a temperature of 70°C, using a DC voltage of 252V (4×63V) and a current density of 35 mA / g, put the anode block into the electrolyte containing phosphate glycol (the concentration of phosphoric acid in the electrolyte is 0.3% by volume, and the concentration of ethylene glycol is 30% by volume) in the tank, and the dielectric layer is ...

Embodiment 3

[0060] This embodiment provides yet another method for manufacturing a solid chip tantalum electrolytic capacitor, specifically as follows:

[0061] Select flake tantalum powder with a specific volume of 9000UuF.v / g and a breakdown voltage of 240V as the raw material, and press the powder into a certain size and quality with tantalum wire leads according to the pressing density of 6.0-8.0 g / CC. Anode blanks. Then carry out vacuum sintering in the range of 1600-1800 degrees, and gradually reduce the vacuum degree four times when it is out of the furnace, each time to ensure that the vacuum degree is not reduced by more than 0.25Ma. After passivation, the tantalum green blocks will not be excessively oxygenated. Therefore, it is ensured that the times of folding of the tantalum wire on the compact after sintering are not less than 4 times. Ensure that the strength and density of the anode meet the requirements of the design value;

[0062] At 60 ~ 85 degrees, use 260V DC voltag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com