Liquid level on-line measurement method based on magnetic buoyancy

A measurement method and liquid level technology, which is applied in the direction of buoy liquid level indicator, etc., can solve the problems of unstable concentration level, high humidity, high speed and accuracy of liquid level measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

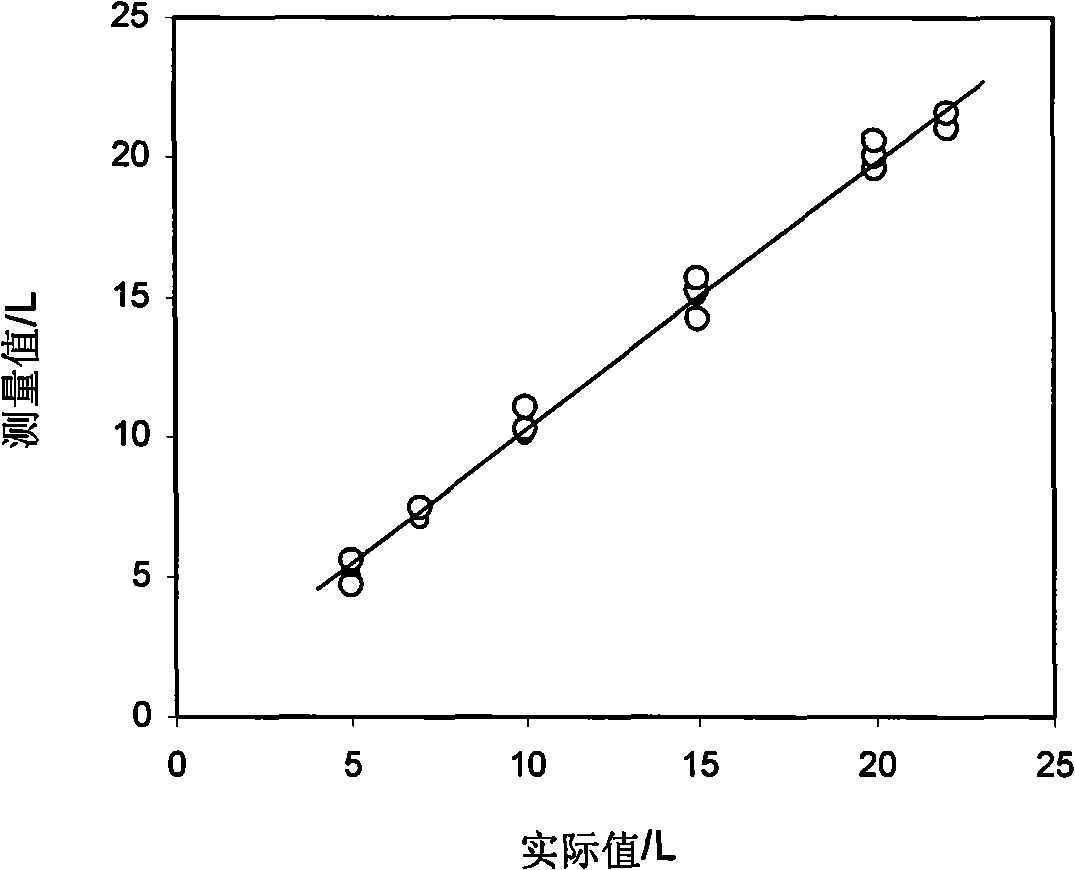

Embodiment 1

[0015] (1) Application of multi-effect evaporator, see figure 1 , the multi-effect evaporator is composed of evaporation chamber 1, boiling chamber 2, magnetic float level gauge 3 and connecting pipe 4, evaporation chamber 1 and boiling chamber 2 are connected through connecting pipe 4, and magnetic floating ball level gauge 3 is mainly composed of magnetic floating ball 5 , sensor 6 and transmitter 7, the magnetic floating ball 5 and sensor 6 are installed in the boiling chamber 2, when the magnetic floating ball 5 floats up and down with the change of liquid level, the magnetic steel in the floating ball is attracted to the corresponding position in the sensor 6 The dry reed switch changes the total resistance (or voltage) of the sensor, and then the transmitter converts the changed resistance (or voltage) signal into a 4-20mA current signal output;

[0016] The magnetic float level gauge can use the CTT001 magnetic buoyancy level gauge manufactured by Shanghai Xiongfeng Aut...

Embodiment 2

[0021] (1) System calibration

[0022] A CTT001 magnetic buoyancy liquid level gauge is installed in the multi-effect evaporator used in the pilot test implemented by the present invention, and the one-to-one correspondence between the liquid level of the evaporator and the position of the magnetic floating ball is calibrated with clear water and ethanol solution respectively. System calibration can be done by addition or subtraction. Addition is to add liquid quantitatively to the lower limit of the liquid level gauge, calibrate the minimum volume, then add liquid quantitatively in batches, and record the amount of liquid added and the position of the magnetic floating ball one by one. Repeat the operation until the upper limit of the liquid level gauge scale. The scheme of subtraction calibration is: first quantitatively add liquid to the upper limit of the liquid level gauge, calibrate the maximum volume scale, and then release the liquid quantitatively from the bottom val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com