Measuring device of friction coefficient of papilionaceous optical cable and measuring method of measuring device

A friction coefficient and measuring equipment technology, applied in measuring devices, instruments, and mechanical devices, etc., can solve problems such as difficulty in ensuring uniform speed, prone to displacement, inaccurate traction force, etc., to reduce human and equipment errors and ensure accuracy. and reliability, reducing waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

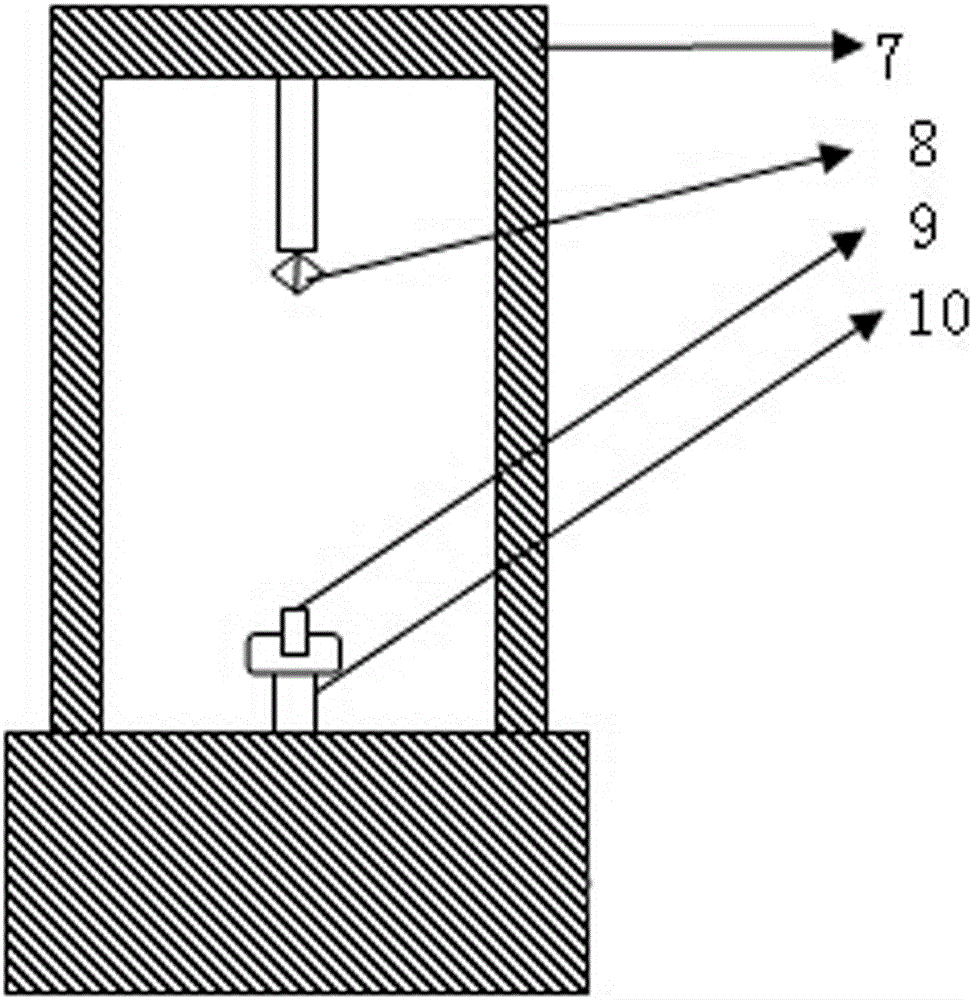

[0021] Such as figure 1 , 2 As shown, a measuring device for the friction coefficient of a butterfly optical cable includes a friction coefficient test bench, an electronic universal testing machine, a computer terminal and an electronic balance. The friction coefficient test bench includes a base with a height adjustment knob, and a stainless steel The cover plate and the bottom plate are placed parallel to each other up and down. There is a weight on the top of the cover plate. A tension arm and a pulley bracket are fixed on the electronic universal testing machine. The pulley bracket is located directly below the tension arm. A clamp is installed at the end of the tension arm. There are fixed pulleys.

[0022] A method for measuring a measuring device for a butterfly optical cable friction coefficient, comprising the steps of:

[0023] Step 1: Adjust the position of the fixture to the starting position of the electronic universal testing machine, select a fixed pulley wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com