Heat exchanger sealing strip surface treatment device

A surface treatment device and surface treatment technology are applied to the cleaning method using tools, the cleaning method using gas flow, the cleaning method and utensils, etc., which can solve the problems of easy swinging of seals, low efficiency, and affecting the quality of surface treatment, and achieve Convenient manual operation, good use effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Because the existing seal surface treatment device has some defects in the seal treatment, for example, the surface treatment of the seal usually relies on the experience of the master to adjust the brush height up and down to process the surface of the seal, which cannot be visualized and can only be processed on one side, so we are here Based on the defects of the prior art, a device for surface treatment of heat exchanger seals is designed, which has high efficiency and can simultaneously process both sides of the seals, which is convenient for people to use.

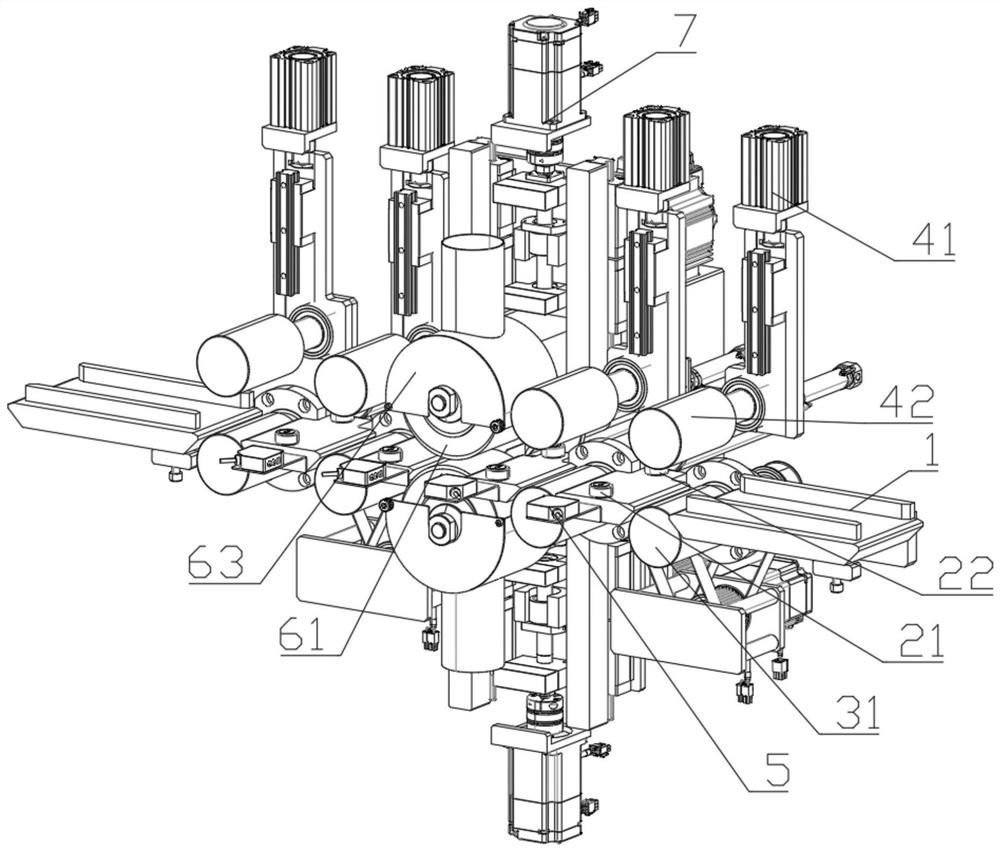

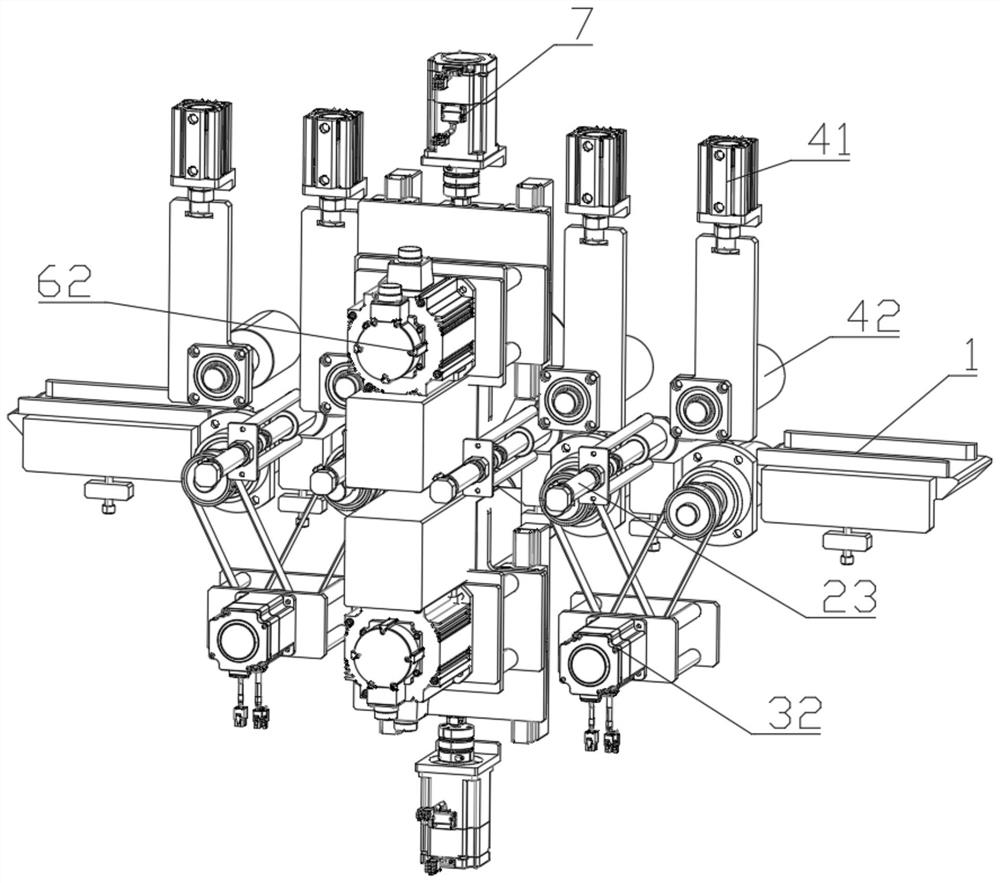

[0020] In order to facilitate those skilled in the art to make this technical solution more clear, the following will be combined with the attached figure 1 -2 elaborate technical solutions of the present invention:

[0021] A device for surface treatment of heat exchanger seals, comprising a workbench 1, a limit mechanism is provided above the workbench 1, and a rolling mechanism is provided below the workben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com