Tobacco planting furrowing and fertilization machine based on diesel engine power

A diesel engine and power technology, which is applied in the field of tobacco planting furrow fertilizer machine, can solve the problems of low efficiency, high labor intensity of operators, inconvenient walking and operation, etc., and achieve the effect of fast and small radius turning and convenient manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above-mentioned features and advantages of the present invention easier to understand, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

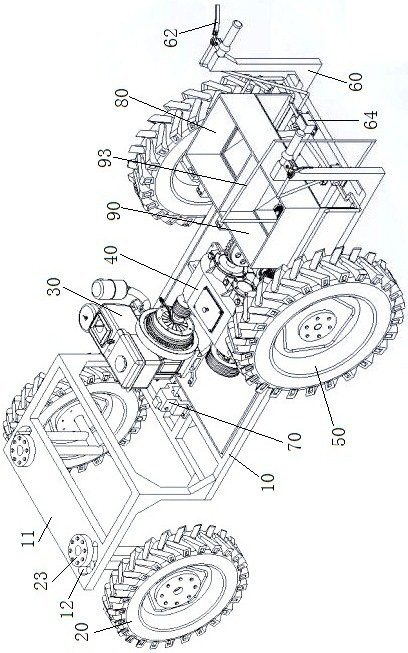

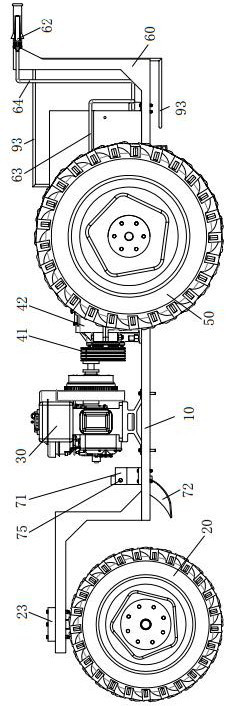

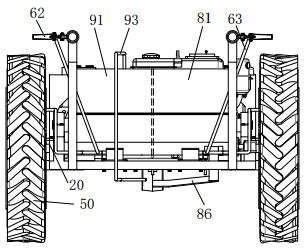

[0031] refer to Figure 1 to Figure 6

[0032] A diesel-powered tobacco planting ditch fertilizer machine comprises a vehicle frame 10, front wheels 20 for steering are respectively arranged on both sides of the front part of the vehicle frame, and front wheels 20 for steering are respectively arranged on both sides of the rear part of the vehicle frame. The rear wheels 50 driven by the transmission mechanism 40 are respectively provided with armrest frames 60 on both sides of the rear end of the vehicle frame. The armrest frames are provided with braking devices for controlling the speed of the rear wheels on the corresponding sides. The front side of the vehicle frame The middle part is provided with a ditch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com