Oxide nanocrystalline synthesis method

A synthesis method and oxide technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of harsh test conditions, poor monodispersity and weak stability of nanocrystals, and achieve good monodispersity , strong stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

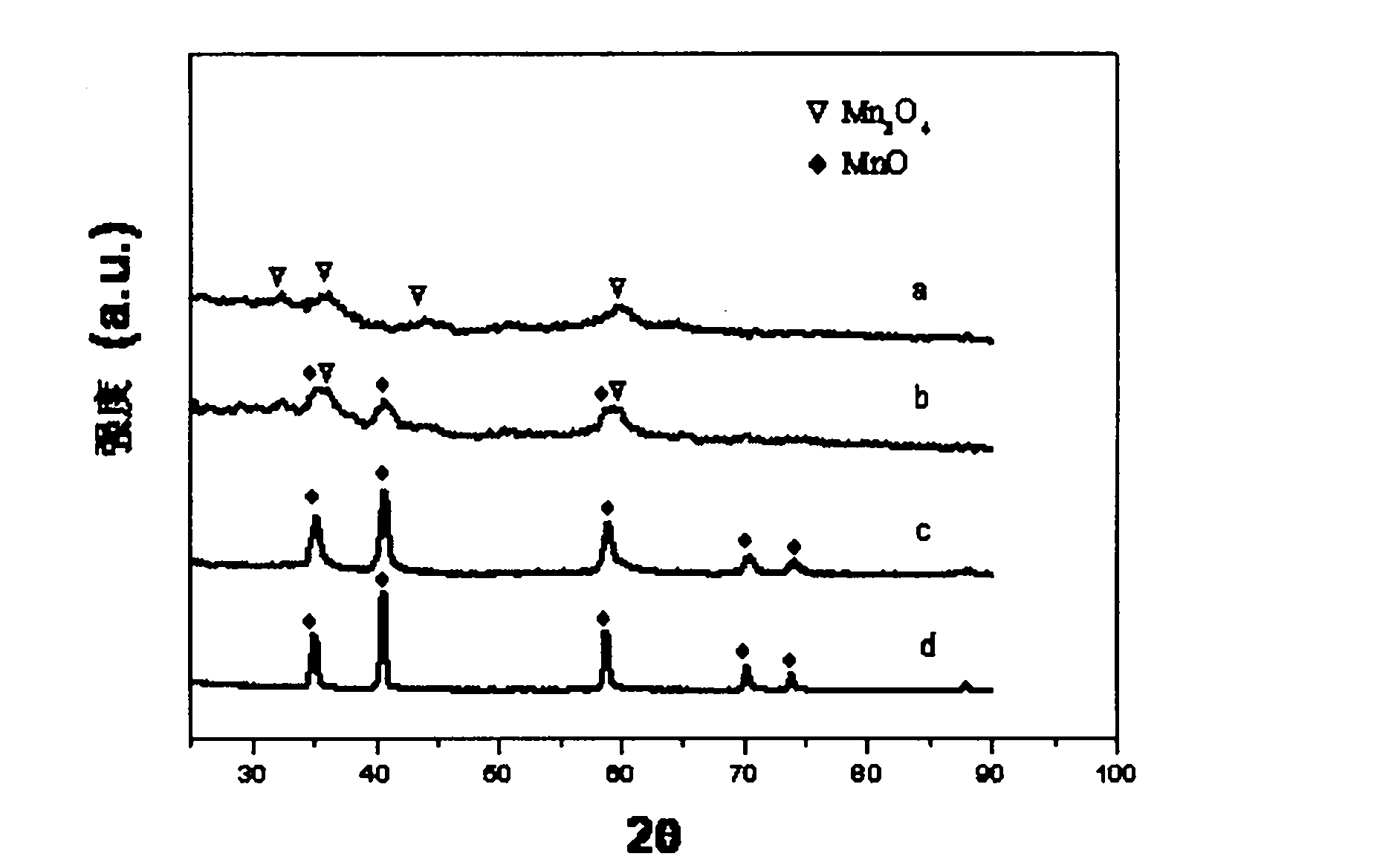

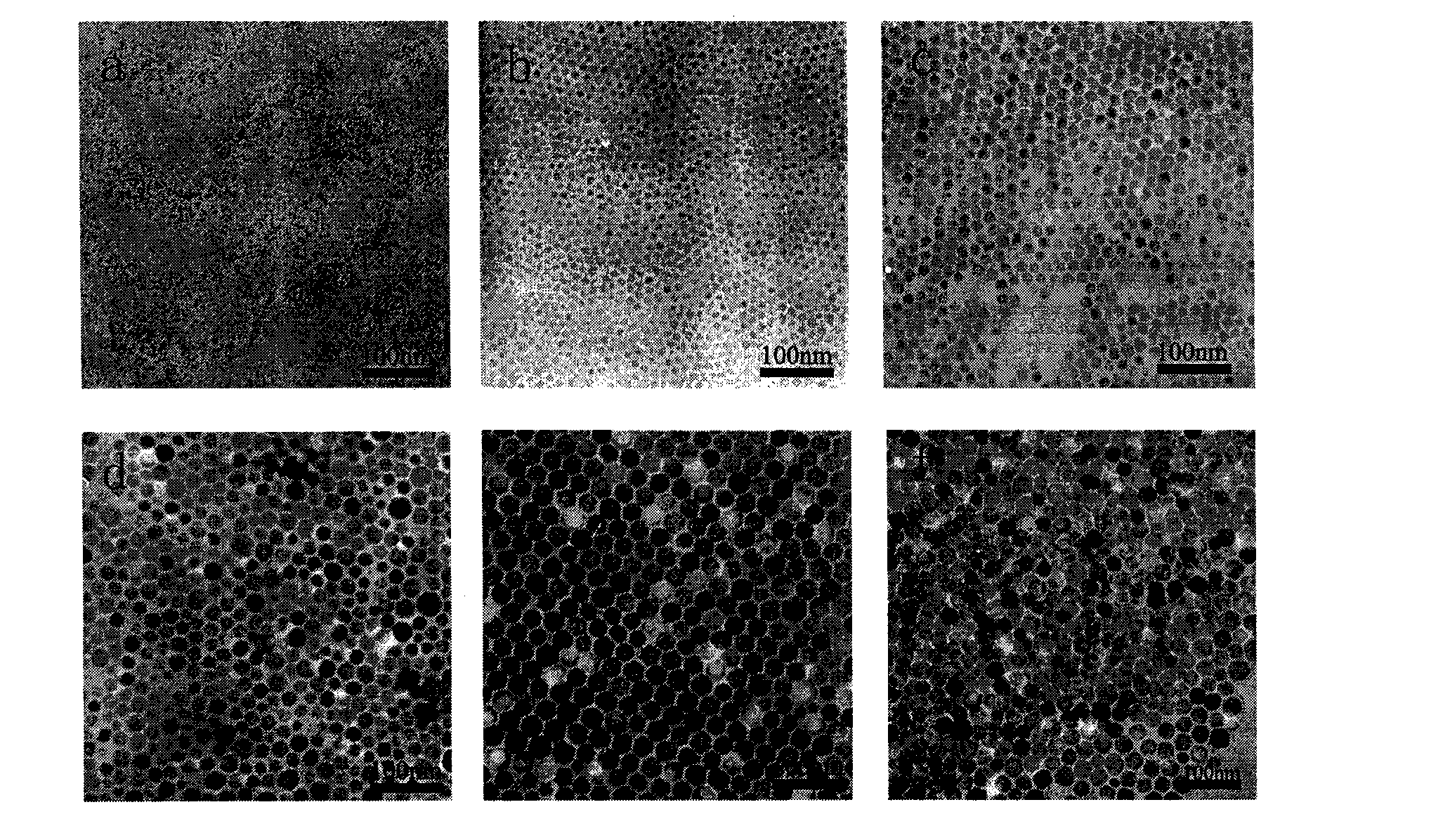

[0066] Manganous acetonide (0.506g, 2.0mmol), liquid paraffin (10mL), oleic acid (0.285g, 1.0mmol), oleylamine (0.803g, 3.0mmol), dodecanol (0.559g, 3.0mmol) Mix in a 50mL three-necked bottle; under nitrogen protection, the mixed solution was heated to 220°C for 2-3 minutes; then liquid paraffin (5mL) was quickly injected into the above solution and the reaction temperature dropped rapidly by 20-40°C; Set at 190°C for 60 minutes. Finally a black clear solution was formed which was slowly cooled to room temperature. Pour the above black solution into a separatory funnel containing a mixed solution of n-hexane (10 mL) and methanol (100 mL). Mix evenly and slightly heat (60-80°C) to precipitate out precipitates. The above purification is carried out 5 times, and finally a Mn of about 5nm can be obtained. 3 o 4 Nanocrystalline. The above-mentioned nanocrystalline precipitates can be easily dissolved in organic solvents such as n-hexane, octane, and toluene. Its X-ray diffrac...

Embodiment 2

[0068] Manganous acetonide (0.506g, 2.0mmol), liquid paraffin (10mL), oleic acid (0.285g, 1.0mmol), oleylamine (0.803g, 3.0mmol), dodecanol (0.559g, 3.0mmol) Mixed in a 50mL three-necked bottle; under the protection of nitrogen, the mixed solution was heated to 280°C for 2-3 minutes; then 5mL of liquid paraffin was quickly injected into the above solution, and the reaction temperature dropped rapidly; at the same time, the temperature was set at 250°C and kept for 60 Minutes, finally forming a black clear solution slowly cooled to room temperature. Purification method is with embodiment 1. Finally, MnO nanocrystals of about 15nm can be produced. By adjusting the injection temperature (240-330°C), we can obtain nanocrystals of different sizes. The corresponding X-ray diffraction pattern and transmission electron microscope pattern are shown in figure 1 , figure 2 .

Embodiment 3

[0070] Acetaldehyde acetonate iron (0.353g, 1.0mmol), liquid paraffin (10mL), oleic acid (0.285g, 1.0mmol), oleylamine (0.803g, 3.0mmol), dodecanol (0.559g, 3.0mmol) mixed In a 50mL three-neck flask. Under nitrogen protection, the mixed solution was heated to 270°C for 2-3 minutes; then 5mL of liquid paraffin was quickly injected into the above solution, and the reaction temperature dropped rapidly; at the same time, the temperature was set at 240°C for 60 minutes , and finally formed a black clear solution which was slowly cooled to room temperature. The purification method is the same as that in Example 1, and finally Fe of about 4nm can be obtained. 3 o 4 Nanocrystalline. By adjusting the injection temperature (270-330°C), we can obtain nanocrystals of different sizes. Its X-ray diffraction pattern and transmission electron microscope pattern are shown in image 3 , Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com