Unsaturated polyester glass fiber felt plate and production method thereof

A technology of polyester glass fiber and production method, which is applied in the field of glass fiber mat, can solve the problems of inability to produce products with high thickness, high investment cost of process equipment, high requirements for process equipment, etc., and achieve good mechanical strength and excellent mechanical strength. Excellent performance and arc resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

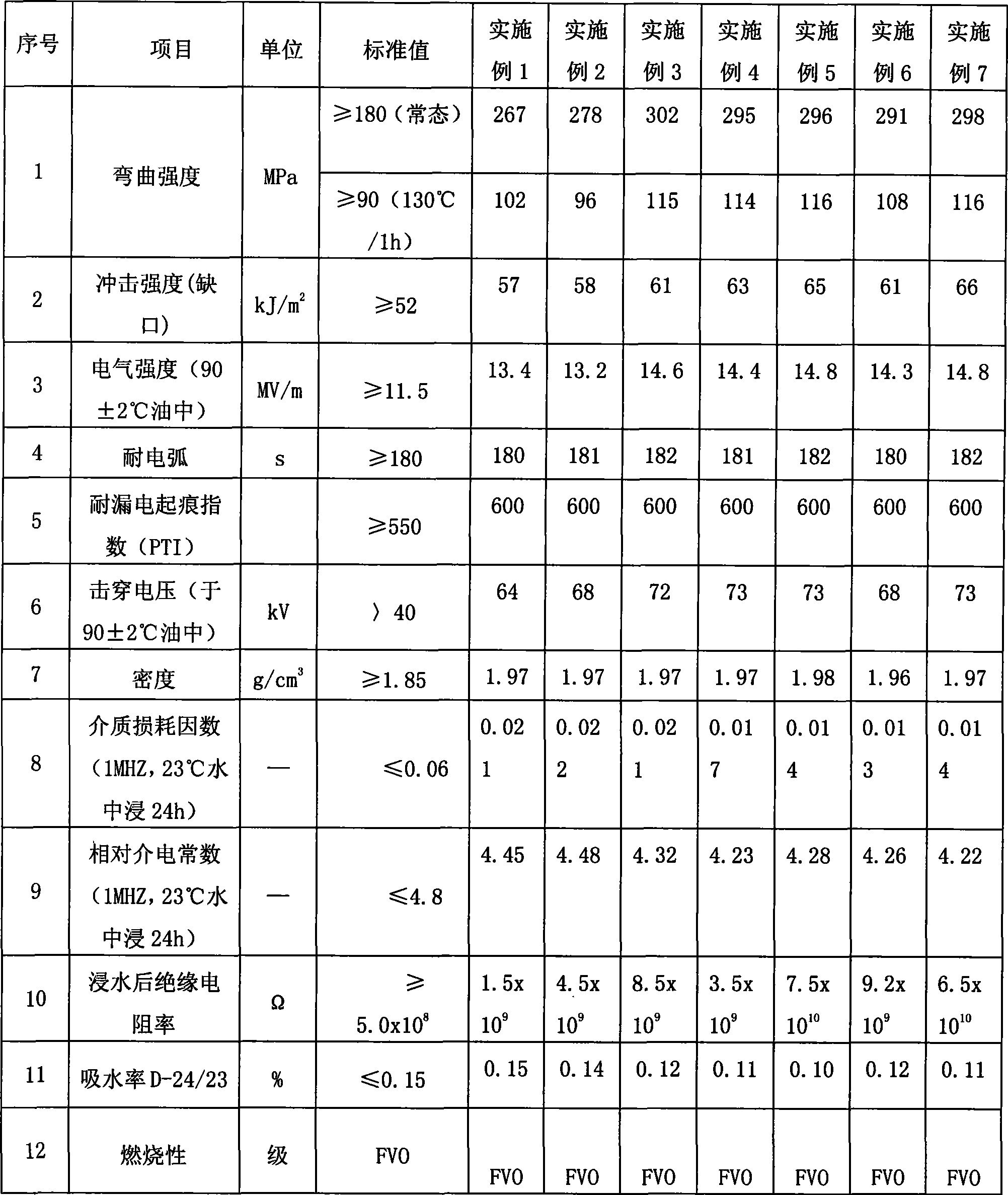

Examples

Embodiment 1

[0044] (1) Add 70Kg o-phthalic polyester resin and 25Kg polyvinyl chloride into the paste mixing tank, adjust the speed of the electric high-speed disperser to 800r / min and stir for 2 minutes, and then add 0.5Kg benzoic acid peroxide, 2.3Kg of hydroquinone and 3.2Kg of color paste, stirred at 800r / min for 3 minutes; under low-speed stirring, add 1.5Kg of stearic acid, 8Kg of antimony trioxide, 0.5Kg of the moisturizer produced by BYK Auxiliary Company of Germany, 800r Stir for 3 minutes at / min; then add 120Kg of aluminum hydroxide filler, gradually increase the speed to 900r / min during the addition process, and stir for 6 minutes; add 4.5Kg of magnesium oxide after the filler is evenly stirred, and stir at a high speed of 1000r / min for 3 minutes, At this time, the resin paste is uniform and free of impurities, and the color tone is consistent.

[0045]Spread the resin paste evenly on the upper and lower layers of polyethylene film, with a thickness of 0.40mm, and then spread ...

Embodiment 2

[0049] (1) Add 90Kg o-phthalic polyester resin and 30Kg polyvinyl chloride into the paste mixing tank, adjust the speed of the electric high-speed disperser to 900r / min and stir for 2.5 minutes, and then add 1.4Kg benzoic acid peroxide, 3.8Kg hydroquinone and 4.2Kg color paste, stirred at 900r / min for 3 minutes; under low-speed stirring, 3.5Kg stearic acid, 9Kg antimony trioxide, 0.9Kg moisturizer produced by BYK Auxiliary Company of Germany, 900r / min Stir for 3 minutes at / min; then add 130Kg of aluminum hydroxide filler, gradually increase the speed to 1000r / min during the addition process, and stir for 6 minutes; after the filler is stirred evenly, add 5.5Kg of magnesium oxide, and stir at a high speed of 1200r / min for 3 minutes, At this time, the resin paste is uniform and free of impurities, and the color tone is consistent.

[0050] Scrape the resin paste evenly on the upper and lower layers of polyethylene film, the thickness is 0.45mm, and then spread a layer of polyet...

Embodiment 3

[0054] (1) Add 78Kg o-phthalic polyester resin and 20Kg polyvinyl chloride into the paste mixing tank, adjust the speed of the electric high-speed disperser to 850r / min and stir for 3 minutes, then add 1Kg peroxide benzoic acid, 3Kg Hydroquinone and 2.5Kg color paste, stir for 3 minutes at 850r / min; add 3.5Kg of stearic acid, 9Kg of antimony trioxide, 0.8Kg of moisturizer produced by German BYK Auxiliary Company under low-speed stirring, 850r / min Stir for 3 minutes; then add 130Kg of aluminum hydroxide filler, gradually increase the speed to 1100r / min during the addition process, and stir for 4 minutes; add 4.8Kg of calcium oxide after the filler is evenly stirred, 1200

[0055] Stir at high speed at r / min for 3 minutes. At this time, the resin paste is uniform and free of impurities, and the color tone is consistent.

[0056] Spread the resin paste evenly on the upper and lower layers of polyethylene film, with a thickness of 0.55mm, and then spread a layer of polyethylene fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com