C5 and/or C6 alkane isomerization process

A technology of isomerization and isomerization of alkanes, which is applied in the field of isomerization of C5 and/or C6 alkanes, can solve the problem of accelerated carbon deposition rate, decreased liquid yield of isomerization products, and affecting the service life of isomerization catalysts To achieve the effect of optimizing isomerized raw materials and prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

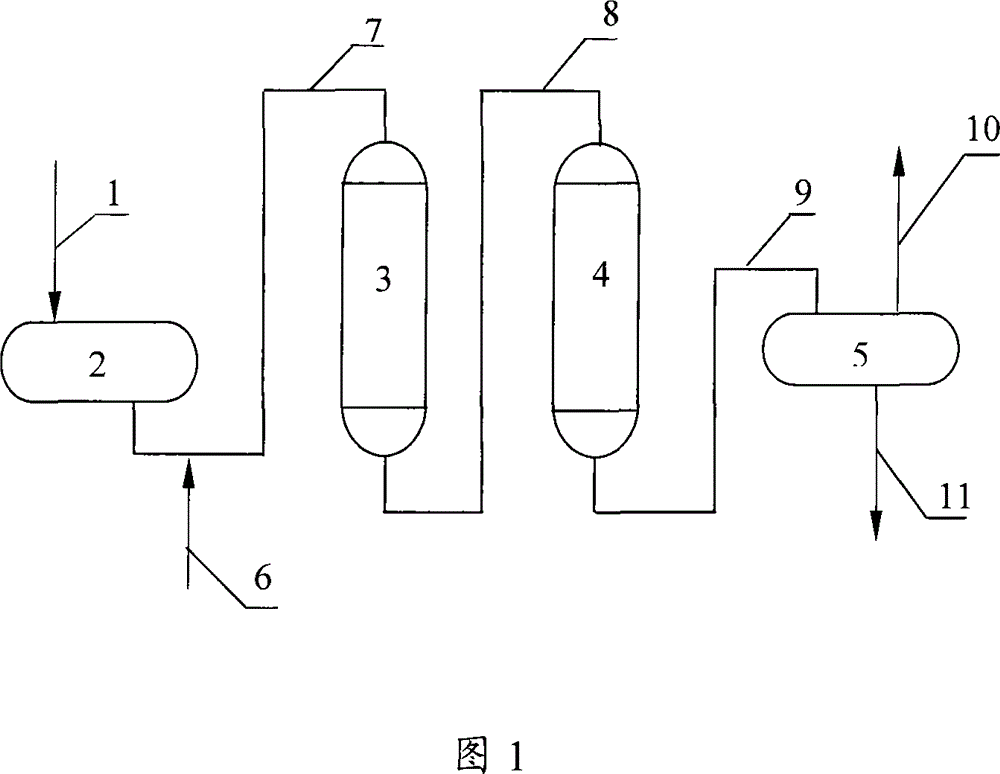

Method used

Image

Examples

example 1

[0024] Prepare the zeolite catalyst according to the method of CN99105790.2 Example 1.

[0025] Get 100 grams of sodium-type mordenite (produced by Fushun Petroleum No. 4 Exchange the Cl solution at 90-95°C for 3 hours, filter, wash the obtained solid with deionized water, dry at 120°C for 3 hours, repeat the operation twice, and then treat it with 800 ml of 1 mol / L hydrochloric acid at 90-95°C for 3 hours , filtered, washed with deionized water until the filtrate was neutral, and roasted at 600°C for 6 hours to make a SiO with a sodium content of 0.03% by mass. 2 / Al 2 o 3 Hydrogen-type mordenite with a molar ratio of 23.4 (measured by fluorescence spectrometry).

[0026] Take 100 grams of sodium Beta zeolite (produced by Fushun Petroleum No. 3 Plant) with a silica / alumina molar ratio of 28.6, and prepare hydrogen Beta zeolite with a sodium content of 0.03% by weight according to the above-mentioned ammonium exchange method.

[0027] Mix the above-mentioned hydrogen-type ...

example 2

[0030] Prepare solid superacid catalyst by the method for CN03105390.4 example 3.

[0031] (1) Preparation of hydrated zirconia

[0032] Halochloride (ZrOCl 2 ·8H 2 O) be made into an aqueous solution of 5% by mass, slowly add ammoniacal liquor with a concentration of 25% by mass while stirring, adjust the pH value to 10, move the resulting zirconium hydroxide precipitate together with the solution to an autoclave for sealing, and perform hydrothermal treatment at 130° C. for 24 hours . The solid was washed with deionized water and filtered until the filtrate was free of chloride ions. Dry at 110°C for 24 hours to obtain hydrated zirconia powder.

[0033] (2) Preparation of a mixture of silica and alumina

[0034] Take 25 grams of silica sol (SiO 2 Content is 41 mass %) join in the solid powder of 54 grams of aluminum hydroxide (Germany, Condea company, brand SB), grind uniformly, 110 ℃ of drying 24 hours, add the NH of 10% 4 200 ml of Cl solution was refluxed under sti...

example 3

[0038] The isomerization reaction is carried out by using the method of the present invention on a small fixed-bed reaction device.

[0039] Charge catalyst A in the reactors connected in series of small fixed-bed devices, and the loading is as follows: 10 grams in the first reactor, and 20 grams in the second reactor. After the filling is completed and the airtight inspection is qualified, hydrogen gas is introduced to raise the temperature to 450°C, reduce for 2 hours, cool down to 220°C, and feed the raw material oil with the composition shown in Table 1, and the feed quality space velocity is 1.2 hours -1 , the hydrogen / hydrocarbon molar ratio is 4, the reaction is under the condition of pressure 1.7MPa, and the temperature of the two reactors is gradually adjusted with the reaction time, and the reaction results are shown in Table 2.

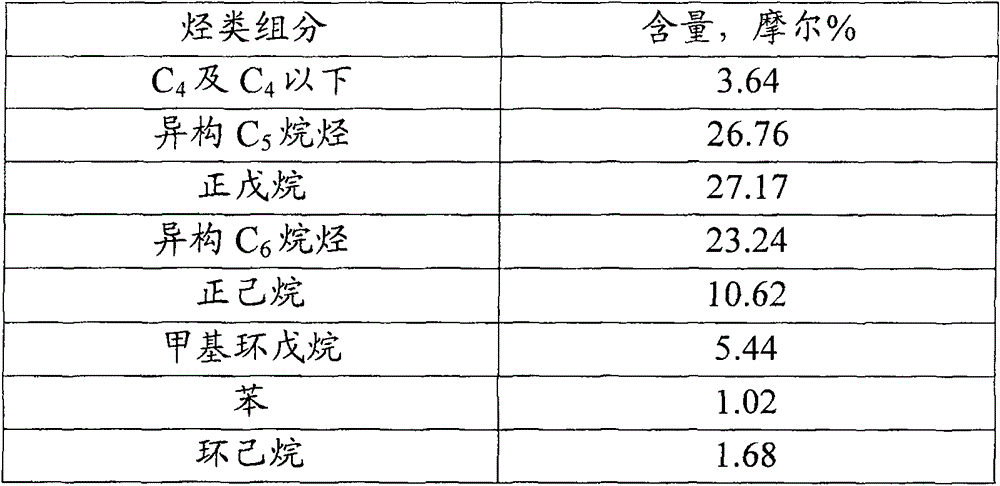

[0040] Table 1

[0041]

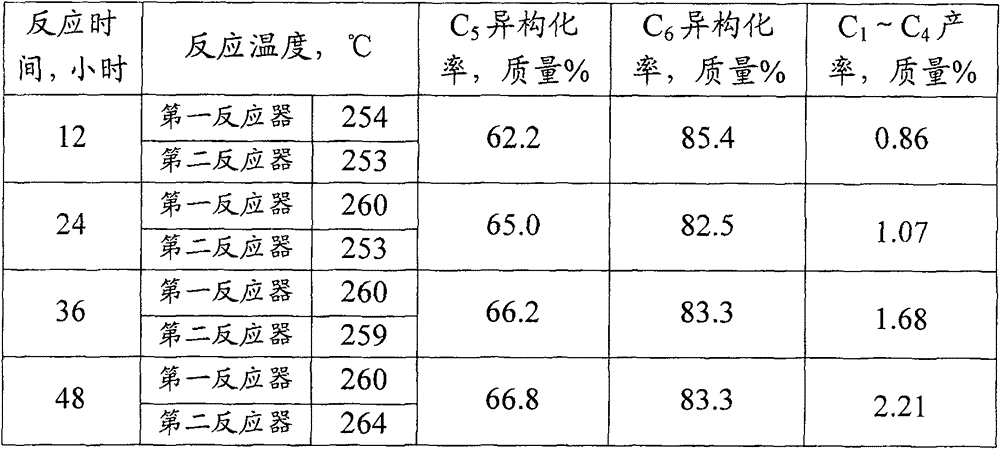

[0042] Table 2

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com