Method for preparing 11-methoxyl-3,7,11-trimethyl-2,4-dodecadienoate

A technology of isopropyl carbadienoate and ammonium carbadienoate, which is applied in the field of preparation of insect growth regulators, can solve the problems of high cis-ester content, affecting product performance, unqualified and the like, avoiding hydrolysis, The effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] The preparation method steps of 11-methoxy-3,7,11-trimethyl-2,4-dodecadienoic acid isopropyl ester of the present embodiment are as follows:

[0009] ① Under a nitrogen atmosphere and stirring, put 54kg of n-hexane and 90kg of 11-methoxyl-3,7,11-trimethyl-2,4-dodecane into a reactor with a reflux condenser successively Dienoic acid ammonium salt (315.8 mol) and 103 kg of tetraisopropyl titanate (362.7 mol). Among them, n-hexane and tetraisopropyl titanate are industrial-grade raw materials.

[0010] ② Turn on the vacuum and keep the vacuum for 5 minutes after reaching 0.05Mpa.

[0011] ③Raise the temperature slowly to 105°C within 25-30 minutes, and maintain at this temperature for 5 minutes to remove ammonia gas.

[0012] ④Raise the temperature to 150°C within 8 to 12 minutes, turn off the vacuum, and keep the temperature at this temperature for 1 hour to complete the reaction.

[0013] 5. the reaction product is rapidly reduced to 10 DEG C, and 53kg of normal hexan...

Embodiment 2~ Embodiment 5

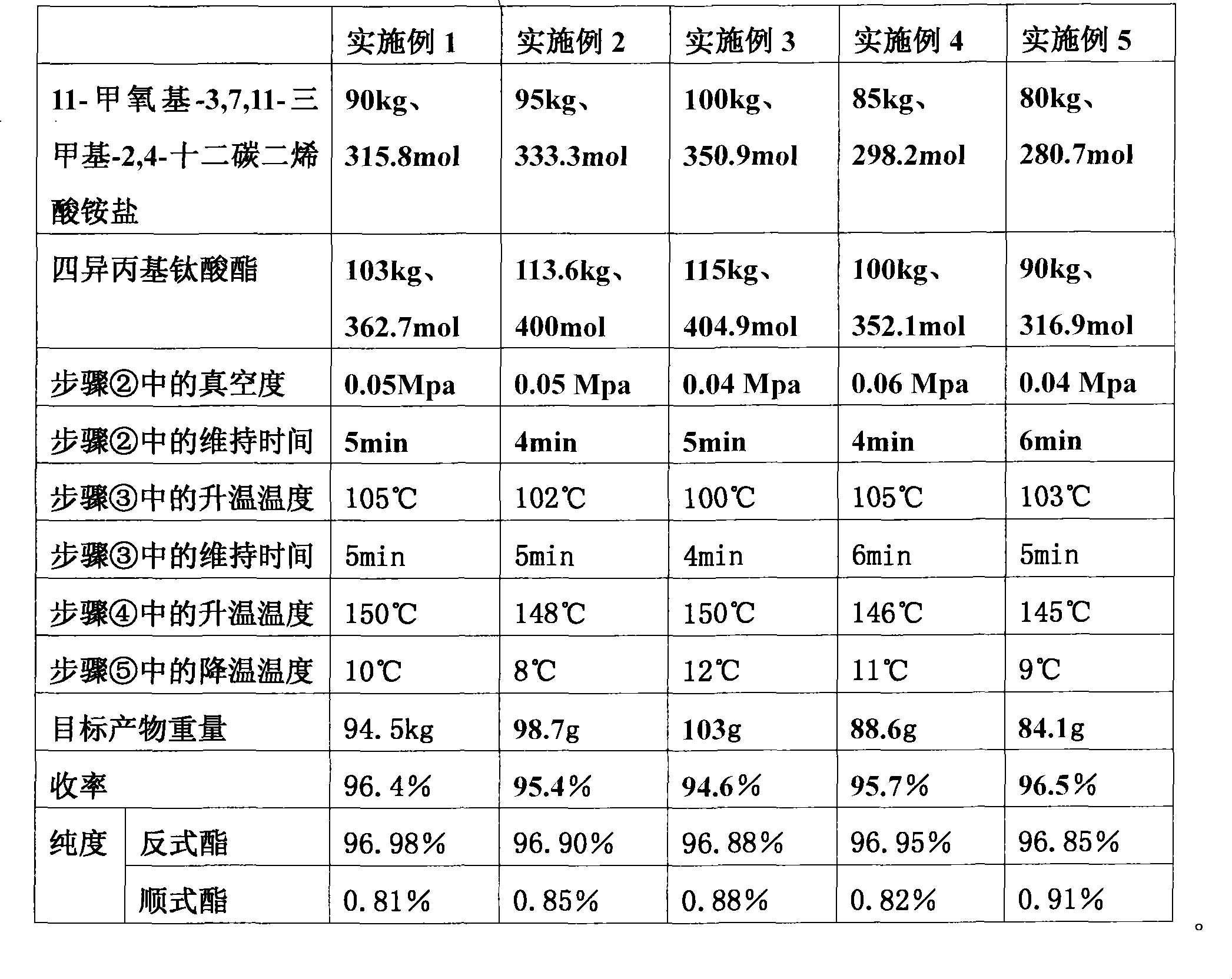

[0015] The preparation method of each embodiment is basically the same as that of Example 1, and the differences are shown in Table 1.

[0016]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com