Preparation method of bamboo leaf flavone

A technology of bamboo leaf flavonoids and extracts, which is applied in food preparation, medical preparations containing active ingredients, food science and other directions, can solve problems such as solvent loss, environmental pollution, poor selection of raw materials, etc., and achieve improved purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Example 1 HPLC method for screening high-content bamboo leaf total flavonoids method

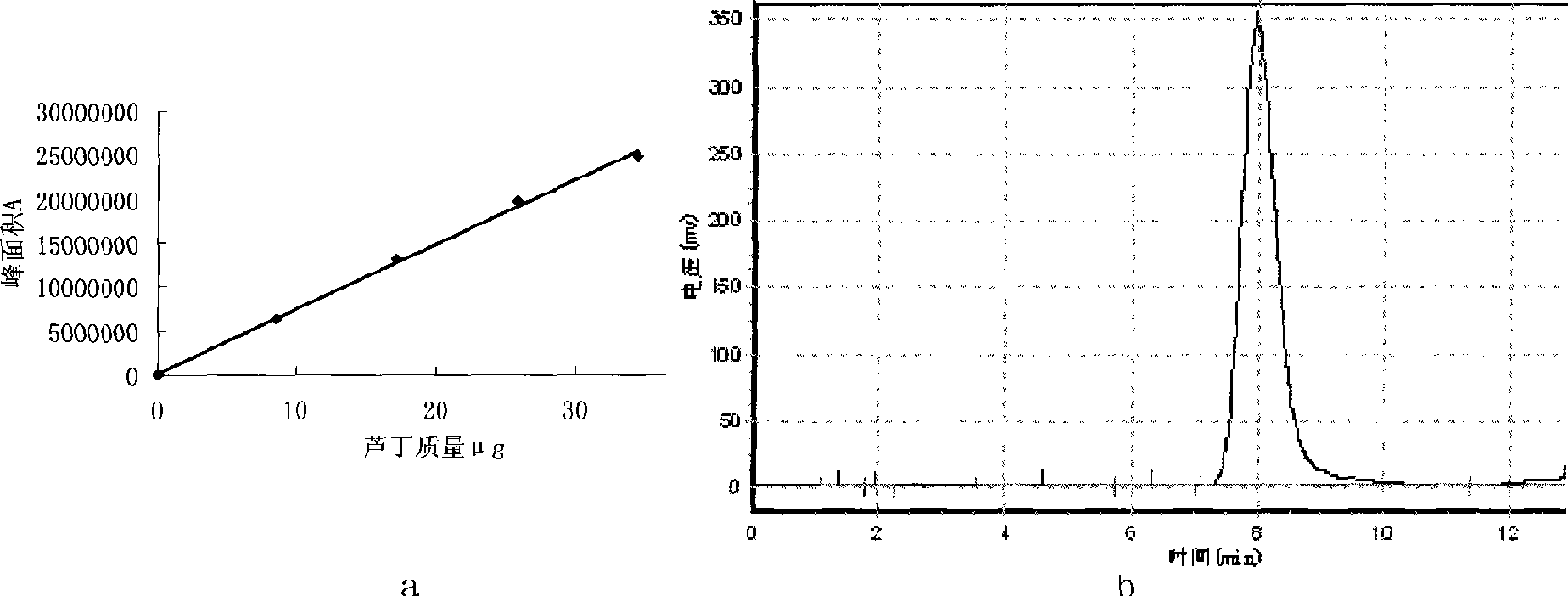

[0086] (1) HPLC rutin standard solution: Accurately weigh 8.6 mg of rutin standard, dissolve in methanol in a 5 mL volumetric flask, and inject samples with different volumes. The standard equation is Y=746447X+262797.

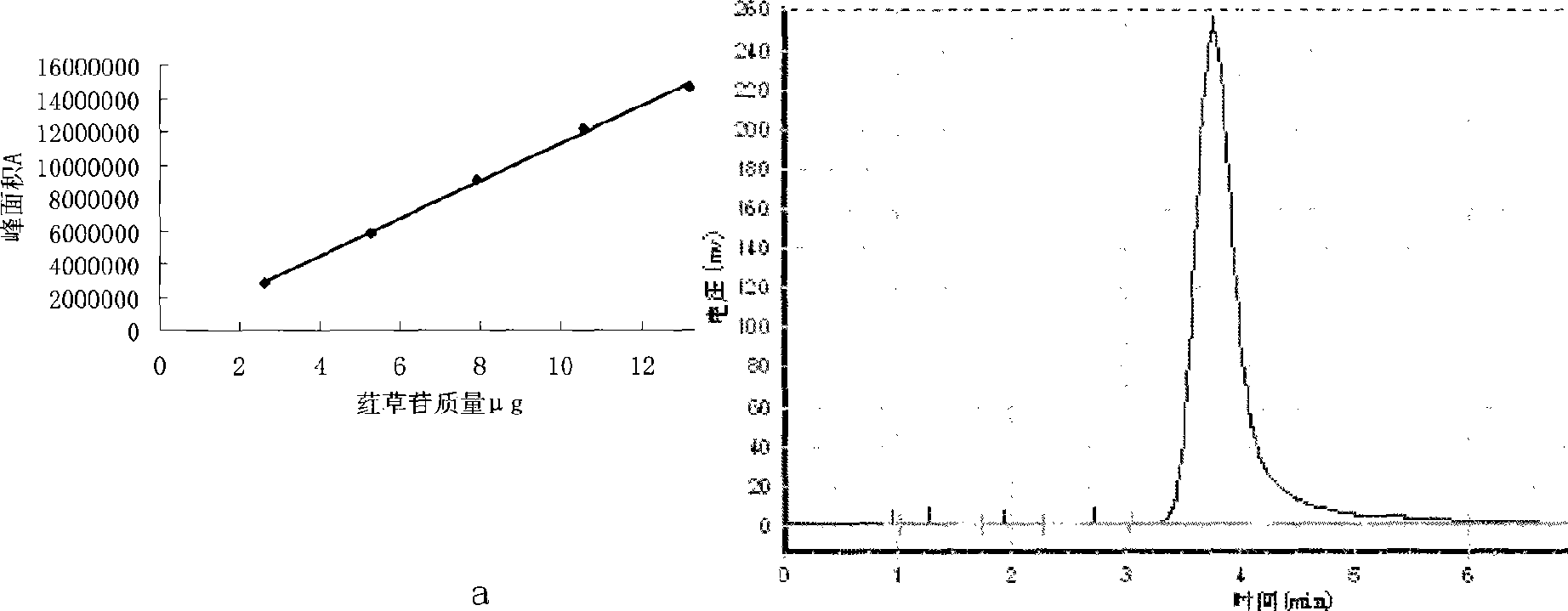

[0087] (2) Orientin standard solution: Accurately weigh 3.3 mg of rutin standard, dissolve in methanol into a 5 mL volumetric flask, inject samples with different volumes, and the standard equation is Y=1155779X-47710.

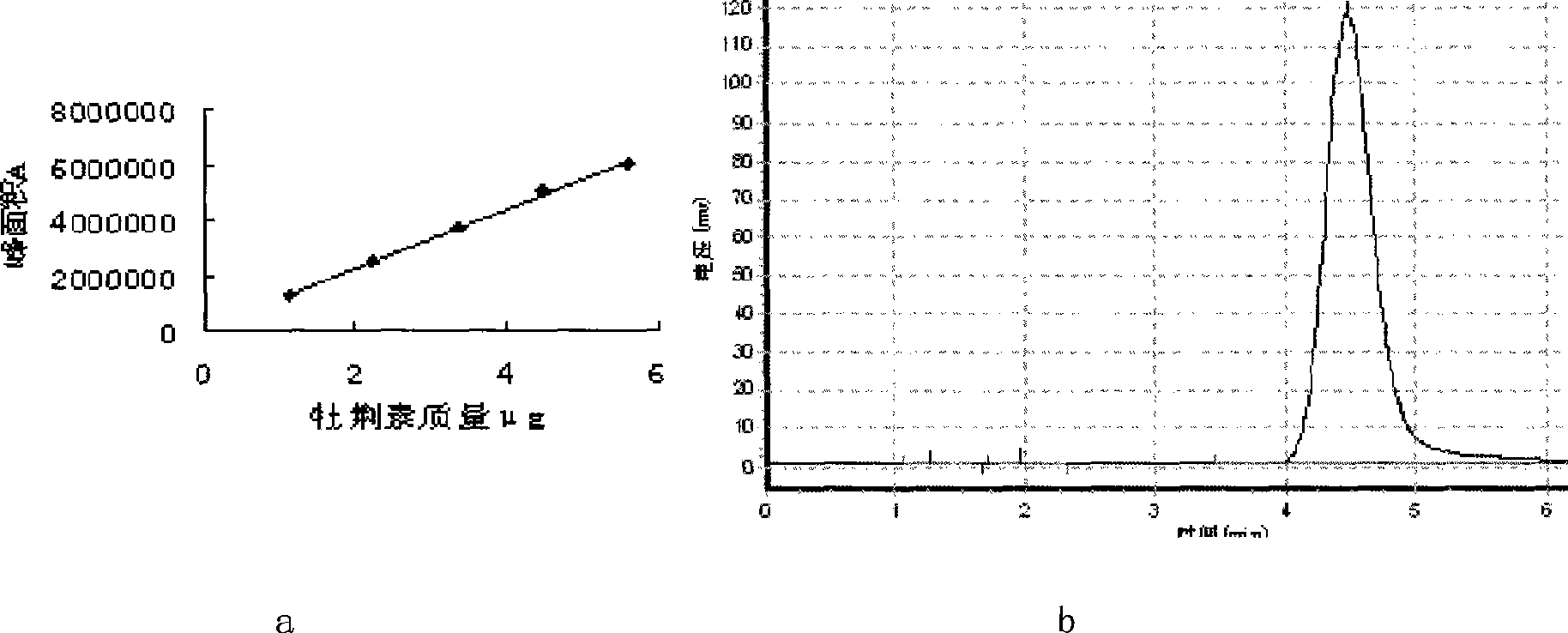

[0088] (3) Vitexin standard solution: Accurately weigh 2.8 mg of rutin standard, dissolve in methanol in a 5 mL volumetric flask, and inject samples with different volumes. The standard equation is Y=1091100X+90365.

[0089] (4) 5% NaNO 2 Solution: Accurately weigh 2.5g NaNO 2 Solid, dissolved in distilled water and fixed volume in 50mL volumetric flask, set aside.

[0090] (5) 10%Al(NO 3 ) 3 Solution: Accurately weigh 5g Al(NO 3 ) 3 Solid, dis...

Embodiment 2

[0099] (1) Screening the lower part of Bamboo gooseberry in Nanjing area, drying the bamboo leaves at low temperature and avoiding light, and pulverizing, wherein the water content is 5.4%wt, and the content of flavonoids is 1.63%wt;

[0100] (2) Get 19 kg of pulverized bamboo leaves and extract them with 6 times the quality of industrial methanol; the extraction temperature is 50° C., the extraction time is 3 hours, and the extraction times are twice;

[0101] (3) Filtrate the leachate, concentrate in vacuum to 50 L, and the vacuum concentration temperature does not exceed 65° C. to obtain crude extract of bamboo leaves.

[0102] (4) Dilute the crude extract with water to 200L and filter to remove impurities

[0103] (5) After passing through a microporous membrane of 0.1 μm, the polysulfone membrane (PS) ultrafiltration membrane has a molecular weight cut-off of 4000; the nanofiltration membrane with a molecular weight cut-off of 400 is separated, and the material membrane f...

Embodiment 3

[0107] (1) Screening the lower part of the water bamboo in Nanjing area, drying the bamboo leaves at low temperature and avoiding light, and pulverizing them, wherein the water content is 5.5%wt, and the flavonoid content is 1.72%wt;

[0108] (2) Get 10 kg of pulverized bamboo leaves and extract with 80% ethanol with a mass concentration of 10 times the mass; the extraction temperature is 60° C., the extraction time is 10 h, and the extraction times are twice;

[0109] (3) Filtrate the leachate, concentrate in vacuum to 30 L, and the vacuum concentration temperature does not exceed 65° C. to obtain crude extract of bamboo leaves.

[0110] (4) Dilute the crude extract with water to 100L and filter to remove impurities

[0111] (5) Ultrafiltration through a 0.2 μm microporous membrane and a polysulfone membrane (PS) with a molecular weight cut-off of 10,000; separation by a nanofiltration membrane with a molecular weight cut-off of 650, and a material membrane flux of 8 m 3 / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com