Transformer oil base oil and preparation method and applications thereof

A technology of transformer oil and base oil, which is applied in base materials, petroleum industry, and multi-stage serial refining process treatment, etc. It can solve the problems of acid slag polluting the environment, small processing capacity, and high cost, and achieves high yield and good conditions Excellent effect of mild and low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

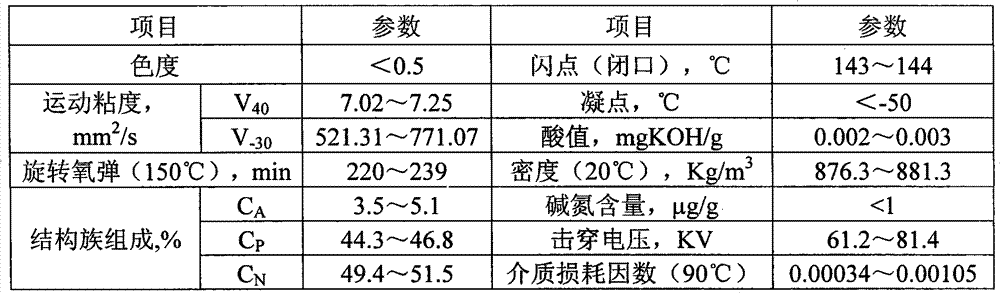

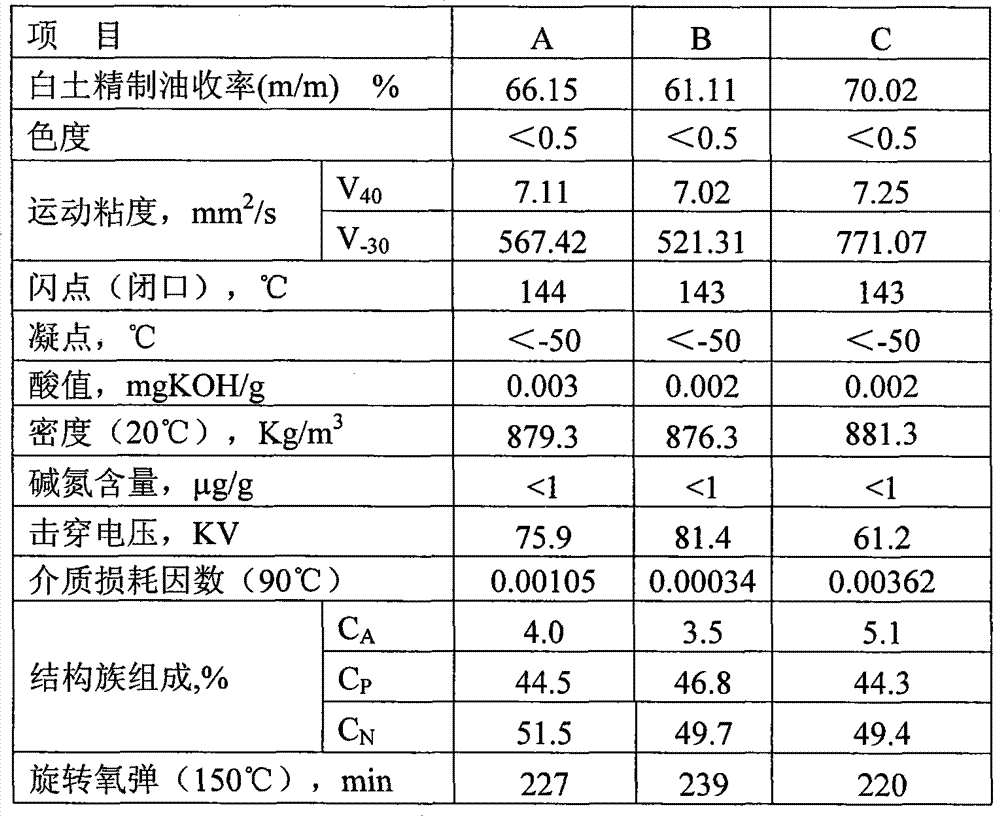

[0042] Embodiment 1, preparation and performance detection of transformer oil base oil

[0043] 1. Preparation of transformer oil base oil

[0044] The test setting was repeated three times, and the performance test results were the average of three copies of product A.

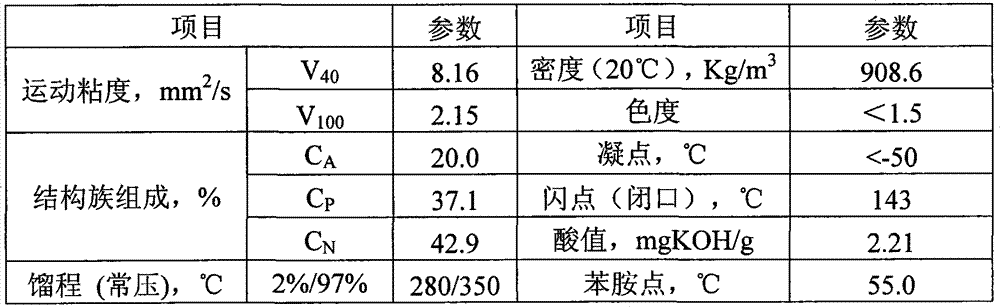

[0045] 1. Furfural refining

[0046] The SZ36-1 normal second-line distillate oil was refined with furfural, the mass ratio of furfural and SZ36-1 normal second-line distillate oil was 1.8:1, the temperature at the top of the tower was 80°C, and the temperature at the bottom of the tower was 50°C to obtain refined oil.

[0047] The furfural solvent in the refined oil is removed by vacuum distillation, and the conditions of vacuum distillation are: 1kpa, 125°C to obtain the dealdehyde refined oil.

[0048] 2. Add 0.2% (mass percentage) denitrification agent to the denitrified refined oil, denitrify at 80° C. for 45 minutes, separate nitrogen residue, and obtain denitrified refined oil. .

[0049] 3. White ...

Embodiment 2

[0053] Embodiment 2, preparation and performance detection of transformer oil base oil

[0054] 1. Preparation of transformer oil base oil

[0055] The test setting was repeated three times, and the performance test results were the average value of three copies of product B.

[0056] 1. Furfural refining

[0057] The SZ36-1 normal second-line distillate oil was refined with furfural, the mass ratio of furfural and SZ36-1 normal second-line distillate oil was 2.2:1, the temperature at the top of the tower was 90°C, and the temperature at the bottom of the tower was 60°C to obtain refined oil.

[0058] The furfural solvent in the refined oil is removed by a vacuum distillation method, and the conditions of the vacuum distillation are: 0.1kpa, 120° C. to obtain a dealdehyde refined oil.

[0059] 2. Denitrification

[0060] Add 0.1% (mass percentage) denitrification agent to the denitrification refined oil, denitrify at 90° C. for 30 minutes, separate the nitrogen residue, and o...

Embodiment 3

[0065] Embodiment 3, preparation and performance detection of transformer oil base oil

[0066] 1. Preparation of transformer oil base oil

[0067] The test set was repeated three times, and the performance test results were the average value of three copies of product C.

[0068] 1. Furfural refining

[0069] The SZ36-1 normal second-line distillate oil was refined with furfural, the mass ratio of furfural and SZ36-1 normal second-line distillate oil was 1.5:1, the temperature at the top of the tower was 70°C, and the temperature at the bottom of the tower was 40°C to obtain refined oil.

[0070] The furfural solvent in the refined oil is removed by a vacuum distillation method, and the conditions of the vacuum distillation are: 2kpa, 130°C to obtain a dealdehyde refined oil.

[0071] 2. Denitrification

[0072] Add 0.3% (mass percentage) denitrification agent to the de-aldehyde refined oil, denitrify at 70° C. for 60 minutes, separate the nitrogen residue, and obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com