Biochemical degradation system coupling hydrolytic acidification-anaerobic and aerobic

A hydrolysis acidification, anaerobic and aerobic technology, applied in the field of environmental engineering and industrial wastewater treatment, can solve the problems of high energy consumption, poor impact resistance, long residence time, etc. The effect of improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

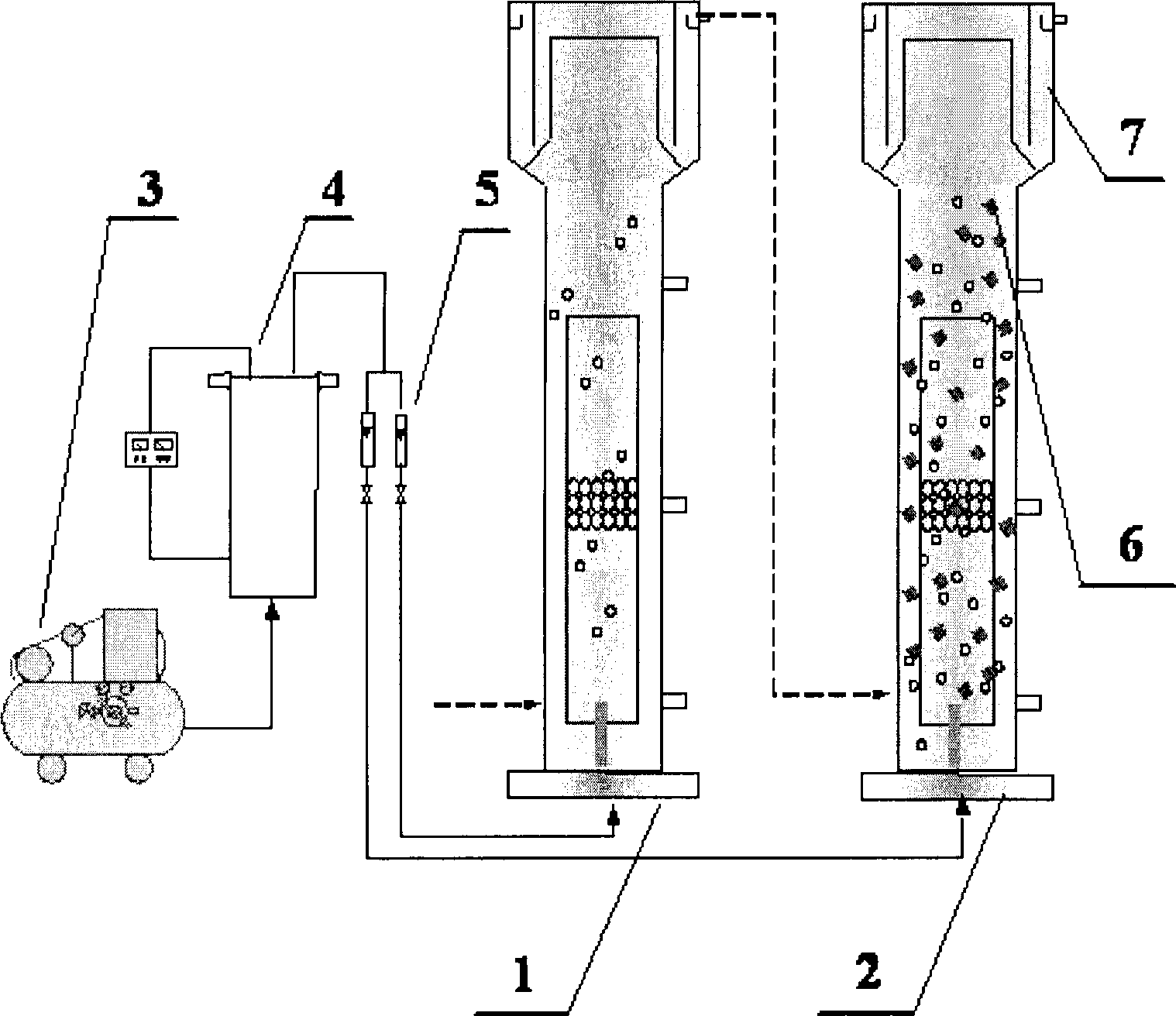

Image

Examples

Embodiment 1

[0032] Example 1: Oxidation-reduction potential of hydrolyzed acidified biological fluidized bed

[0033] Hydrolysis and acidification fluidized bed type: air-lift internal circulation biological fluidized bed; effective volume: 67L;

[0034] Wastewater type: phenolic wastewater; COD: 3200mg / L;

[0035] Superficial gas velocity: 0.01~0.03mm / s; redox potential: -100~0mv.

[0036] It can effectively treat phenolic wastewater.

Embodiment 2

[0037] Example 2: Microbial phase within a macroporous carrier

[0038] Anaerobic and aerobic coupled fluidized bed type: air-lift internal circulation biological fluidized bed; effective volume: 35L;

[0039] Carrier size: 15mm×15mm×15mm; Carrier pore diameter: 1.25mm; Porosity: 90%; The volume ratio of the carrier dosage to the effective volume of the reactor: 10%; The carrier material is polyurethane.

[0040] Wastewater type: terephthalic acid wastewater; COD: 3032mg / L;

[0041] After the sludge is domesticated, a single carrier is taken out to make slices and observed under a scanning electron microscope. It can be found that there is a significant difference between the inner core of the carrier and the external microbial phase. hypoxic area.

Embodiment 3

[0042] Example 3 Treatment effect of hydrolytic acidification biological fluidized bed

[0043] Hydrolytic acidification fluidized bed type: air-lift internal circulation biological fluidized bed; effective volume: 40L;

[0044] Wastewater type: Benzoic acid wastewater

[0045] Superficial gas velocity: 0.2mm / s; redox potential: 50mv;

[0046] The present embodiment influent CODcr is 4900mg / L, BOD 5 1008mg / L, BOD 5 / CODcr is 0.21, after 30 hours of hydraulic retention time, the effluent CODcr is 4355mg / L, BOD 5 2505mg / L, BOD 5 / CODcr is 0.58, and the biodegradability of wastewater is significantly improved after hydrolysis and acidification treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com