Alloying soaking furnace capable of realizing hot dip galvanizing coating alloying annealing curve free inclination of soaking temperature

An annealing curve and alloying technology, which is applied in heat treatment furnaces, hot-dip coating processes, furnaces, etc., can solve the problems of poor anti-powdering performance of coatings, excessive growth of Γ phase in coatings, and greater influence, and achieve Excellent formability and anti-powdering performance of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

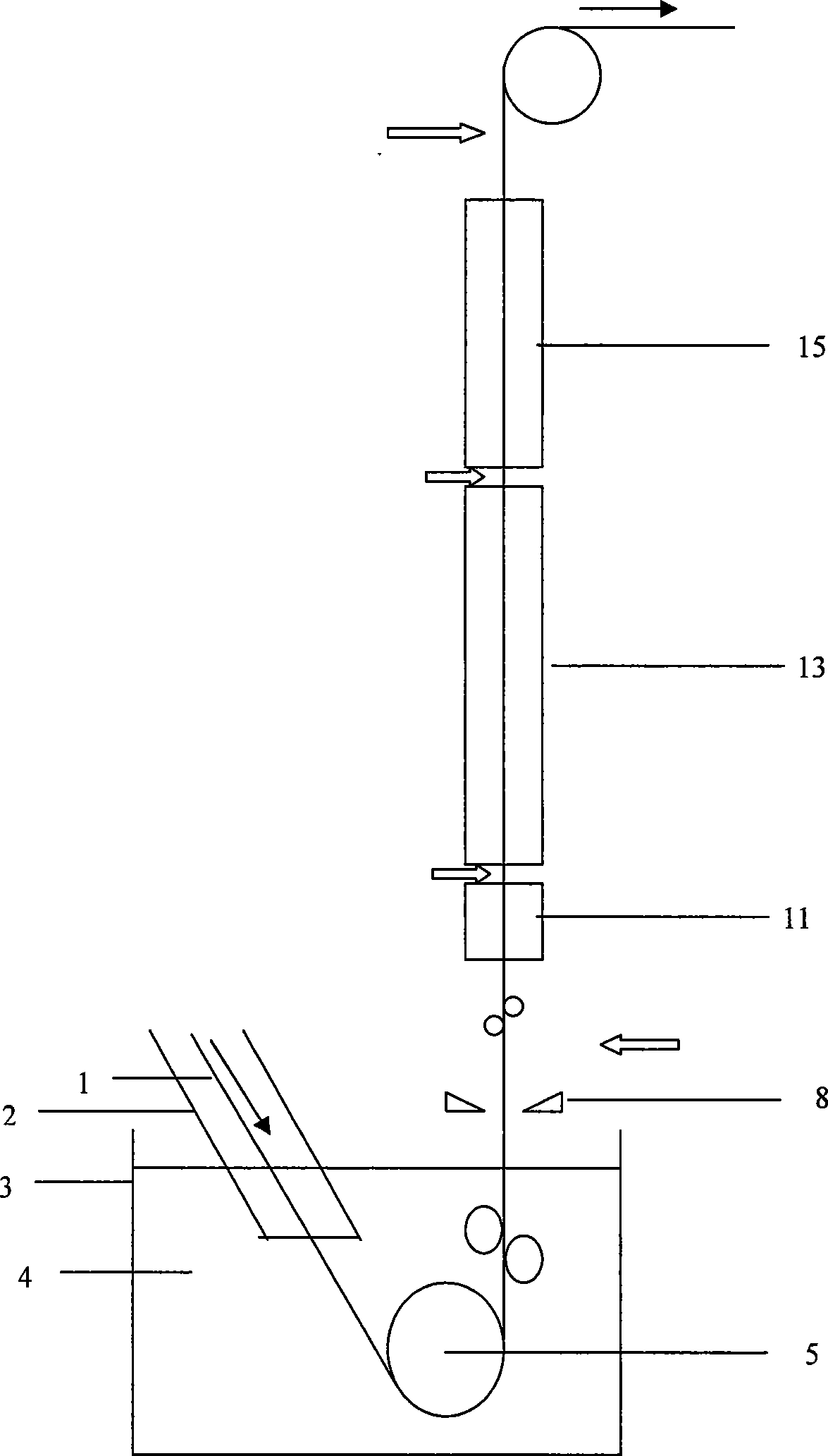

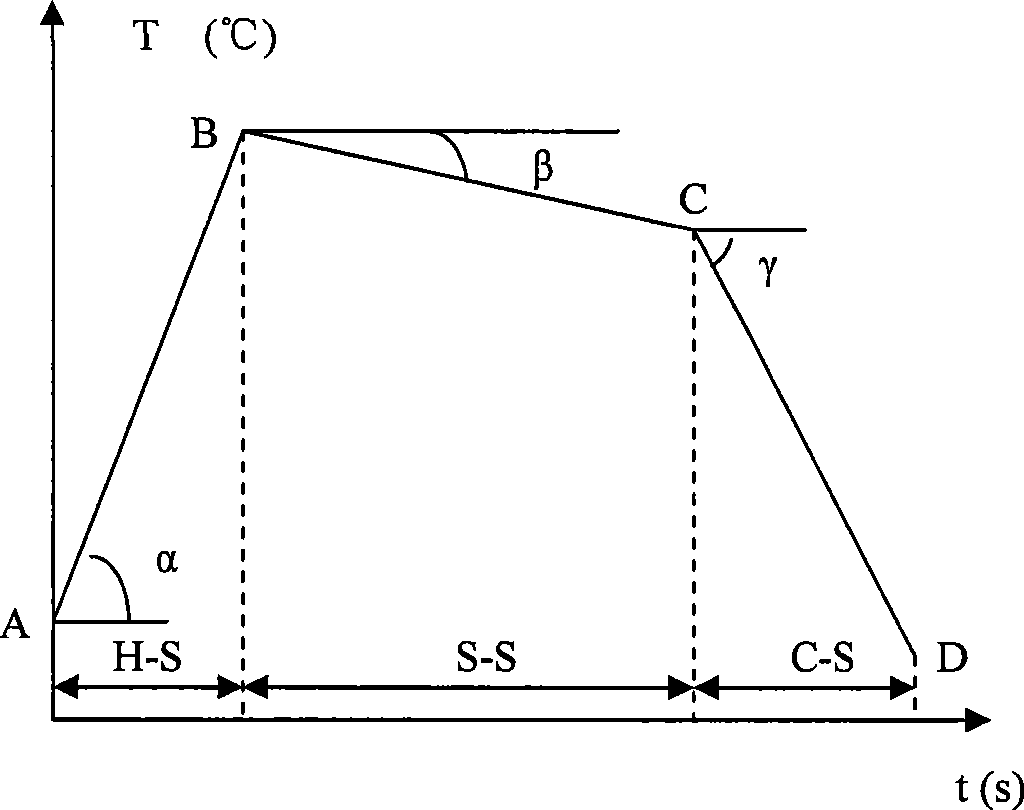

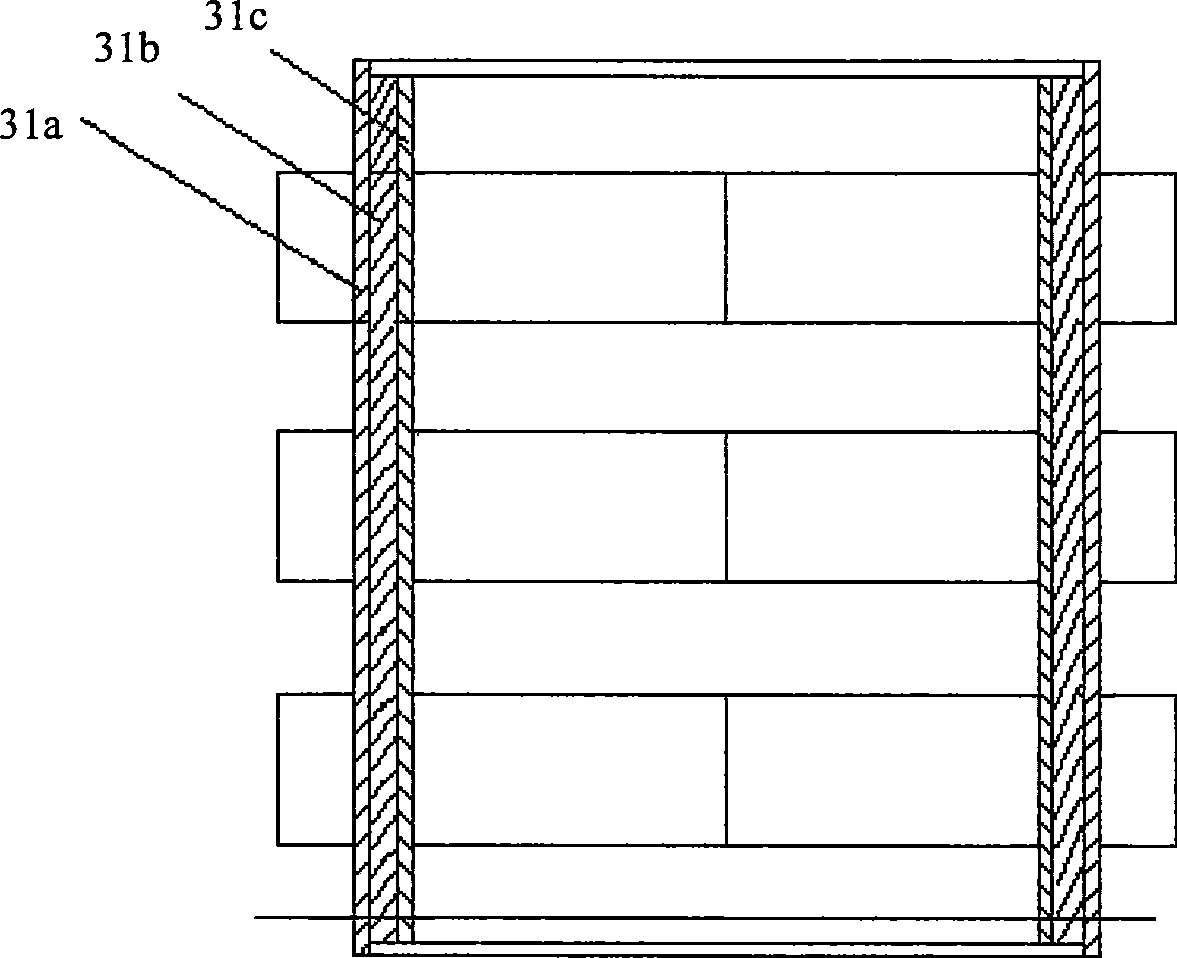

[0027] Example 1: A hot-dip galvanizing line that can produce alloyed hot-dip galvanized products. The strip width specification is: 700-1280mm. The soaking section of the alloying furnace is divided into four sections along the strip running direction, each section is 7.5m, The furnace wall adopts a movable structure, and its details are as follows: Figure 5 shown. Each window is made up of two movable furnace walls 32 whose height H1 is 500mm and can move to both sides. Figure 5a Middle L a shown) is 1080mm. When producing IF steel automotive outer panels with a width of 700mm, the opening width of the window (such as Figure 5b Middle L b Shown) is 300mm (that is, the width of the window after opening is the width of the strip minus 400mm), so that the strip is cooled more evenly along the width direction, and the iron content of the produced strip coating is as shown in Table 1. The iron content of the coating is very uniform.

[0028] Table 1 The iron content of t...

Embodiment 2

[0033] Example 2 (the width of the window after opening is the strip width minus 200mm, and the difference in the iron content of the coating is less than 0.5%): a hot-dip galvanizing unit that can produce alloyed hot-dip galvanized products, and the strip width specification is: 800-1480mm , the soaking section of the alloying furnace is divided into four sections along the running direction of the strip steel, each section is 7.5m long, and the furnace wall adopts a movable structure. Refer to Figure 5a , 5b . Each window is composed of two movable furnace walls with a height H1 of 500mm that can move to both sides. When the movable furnace wall moves to the maximum limit range on both sides, the width of the window (such as Figure 5a Middle L a shown) is 1280mm. When producing bake-hardened steel automotive panels with a width of 1480 mm, the opening width of the window (eg Figure 5b Middle L b Shown) is 1280mm, so that the strip is cooled more uniformly along the w...

Embodiment 3

[0036] Example 3: A unit for producing alloyed hot-dip galvanized products. The strip width specification is: 800-1800mm. The soaking section of the alloying furnace is also divided into four sections along the running direction of the strip, each section is 7.5m. The furnace wall adopts Structural design of opening and closing window insulation cover plate, the furnace wall is divided into five sections along the strip width direction, which can be opened and closed up and down. The middle section (600mm) is controlled separately, and the left section L1 (300mm) and The right segment R1 (300mm) is jointly controlled, and the left second segment L2 (300mm) and the right second segment R2 (300mm) are jointly controlled, specifically as follows Figure 6 shown. When producing alloyed hot-dip galvanized bake-hardening steel with a width of 1680mm, open the middle three covers (total 1200mm wide), so that the strip steel can be cooled more evenly along the width direction, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com