Method for preparing humic acid bio-fertilizer from lignite

A technology of humic acid and biological fertilizer, applied in the direction of organic fertilizer and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

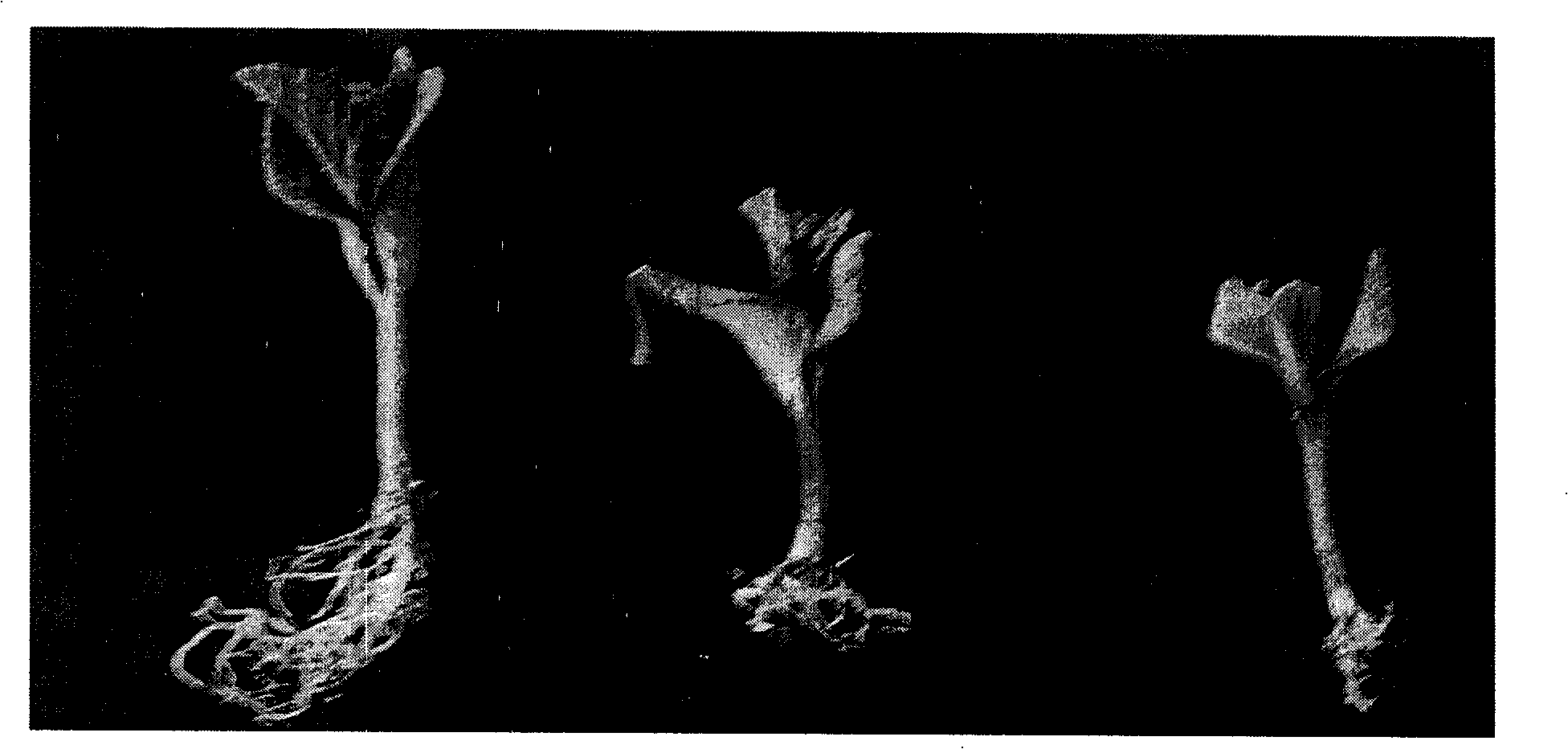

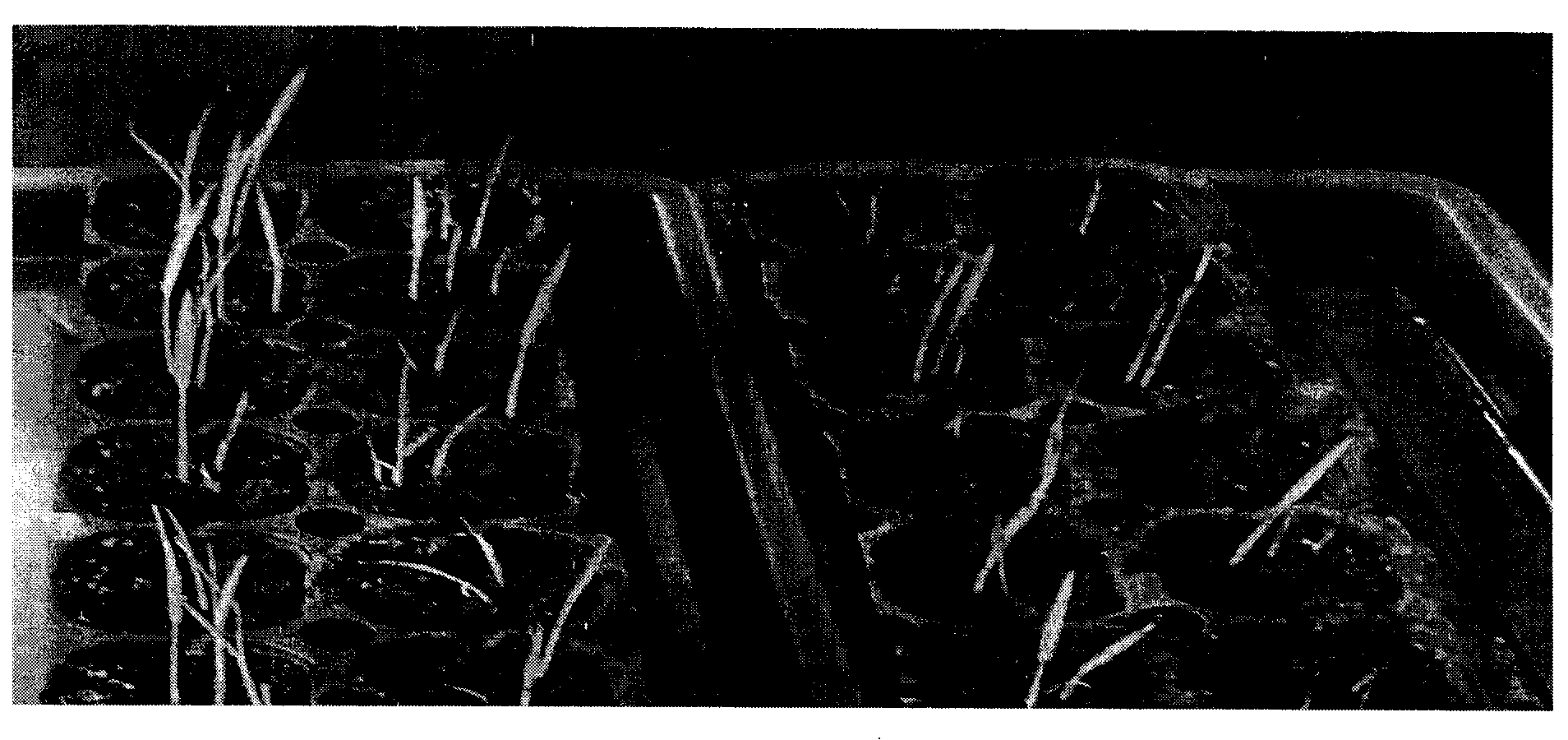

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment the present invention is described in more detail:

[0022] 1.1. Source of fermentation strain

[0023] In this example, Phanerochaete chrysosporium was purchased from the China Industrial Microorganism Culture Collection and Management Center, with the strain number CICC40719, and was used to produce lignin hydrolase.

[0024] 1.2 Strain domestication

[0025] 1.2.1. Contain 100-300ml of KH 2 PO 4 0.3%, MgSO 4 .7H 2 O 0.15% g, Vitamin B 1 O.01%, lignite coal powder 5% deionized water 94.54%. The culture medium was sterilized at 110-150°C for 10-30 minutes, inoculated with Phanerochaete chrysosporium, cultured on a shaker at 28°C for 96 hours, and made into bacterial suspension I;

[0026] 1.2.2. Contain 100-300ml of KH 2 PO 4 0.3%, MgSO 4 .7H 2 O 0.15% g, Vitamin B 1 0.01%, lignite coal powder 10%, deionized water 89.54% medium 110-150 ℃ sterilized 10-30 minutes, inoculate above-mentioned thalline suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com